Rolls-Royce expands partnership with Purdue University

Increased commitment expands Rolls-Royce’s test facilities in the Purdue Aerospace District to develop high-altitude and hybrid-electric engines, advances Purdue’s economic development.

Rolls-Royce has conducted research and development for its jet engine components in the 55,000-square-foot Purdue Technology Center Aerospace since 2017. Photo Credit: American Structurepoint Inc.

Aerospace engine manufacturing company Rolls-Royce (Manchester, U.K.) reports that it will expand its already large footprint at Purdue University (West Lafayette, Ind., U.S.), thanks to a new commitment among the university, the Purdue Research Foundation and the company.

The enhanced partnership, announced Aug. 2, calls for Rolls-Royce to further expand its facilities in the Purdue Aerospace District, which is adjacent to the university. The new test facilities will be used to develop high-altitude and hybrid-electric engines to power the next generation of U.S. military aircraft. Rolls-Royce West Lafayette will be developed through a multimillion-dollar investment from the research foundation, Purdue University and Rolls-Royce North America.

The partnership is said to be a major win for the national security and technology pillar of Purdue’s Next Moves, an initiative designed to advance the university’s competitive advantage announced by President Mitch Daniels and Purdue trustees in April 2021.

The facility will enable Rolls-Royce North America to continue its legacy of providing full-service advanced design, development, production and aftermarket support of world-leading propulsion solutions.

“Purdue is delivering new, one-of-a-kind facilities that are national assets and will further differentiate the university as a state and national leader in securing and defending our country,” Daniels says. “With this vital partnership and support from our good friends at Rolls-Royce and others, we continue to expand our role as the economic engine for this region of Indiana and beyond.”

Rolls-Royce already has facilities focusing on digital engine controls and conducts advanced technology engine research at Purdue's Zucrow Laboratories in the district. It’s part of a longstanding partnership between the company and university spanning several decades of conducting aerospace research. The company also employs hundreds of Purdue engineers.

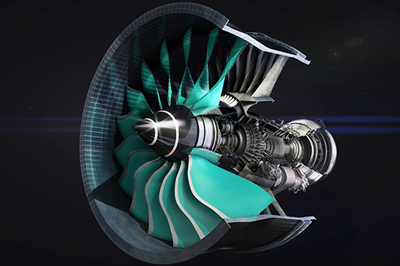

The new facility, according to Rolls-Royce North America, will enable it to continue its legacy of providing full-service advanced design, development, production and aftermarket support of world-leading propulsion solutions, such as the company’s ongoing development of the Ultrafan aeroengine prototype with carbon fiber-reinforced polymer (CFRP) rotor blades.

“Rolls-Royce has a proud history of supporting our U.S. military and commercial customers, and this new significant investment will continue to grow our capability to serve our customers,” adds Tom Bell, chairman and CEO of Rolls-Royce North America. “This reflects yet another major investment in Indiana, and we are also planning significant upgrades to test facilities at our Indianapolis manufacturing campus, which has benefited from a recently completed $600 million modernization program to grow advanced manufacturing and technology capability. We thank both local and state governments for their ongoing support.”

Mung Chiang, Purdue’s executive vice president for strategic initiatives and the John A. Edwardson Dean of the College of Engineering, says testing to be conducted by Rolls-Royce will substantially advance national security. “Today’s announcement is pivotal for two reasons,” Chiang says. “It represents the largest single economic development success to our neighborhood with Rolls-Royce colleagues and the largest research collaboration with a private-sector partner. It also advances the excellence at scale by Purdue in creating the epicenter of aerospace engineering R&D in the U.S.”

Related Content

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreOptimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreRead Next

Purdue University to establish Thermwood LSAM research laboratory

Industry-funded research to pursue large-scale composite thermoplastic additive manufacturing, with the goal of providing services to enhance, encourage and expand the adoption of large-scale AM for diverse industrial applications.

Read MoreTeijin Tenax carbon fiber prepreg adopted for UltraFan aeroengine nacelle

Prepreg developed specifically for aircraft applications using high-performance and rapid-curing epoxy resin, with low-temp molding and automated processing capabilities.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More