National Composites Centre wild water champion spearheads project for U.K.’s first sustainable kayak

A wild water kayak, made from composite materials and manufactured using Recyclamine technology, presents new solutions for sustainability and a challenge for graduate engineering team.

The NCC engineering team that successfully developed the sustainable composite kayak. Photo Credit, all images: NCC

A wild water kayak, made from sustainable composite materials — reported to be a U.K. first — has been designed and manufactured by a team of 19 graduates, apprentices and year-in industry students from the National Composites Centre (NCC, Bristol, U.K.).

Jacob Holmes and Emma Burns, graduate research engineers at the NCC, part of the High Value Manufacturing Catapult, were inspired by Holmes’ history of wild water racing to create a wild water kayak using more sustainable materials and tackle end-of-life (EOL) composites challenges. Jacob has been selected for the senior GB team for five consecutive years and was ranked #2 in the U.K. in 2021.

“The idea for the project came about after the rules for wild water racing kayak dimensions changed this year,” Holmes reflects. “There is now no minimum width, and while this development has been slow over decades, it is potentially set for rapid change. There are currently no white-water racing kayaks made in the U.K. and there is no end-of-life [EOL] solution for them either. We thought this would be a great challenge for our team of young engineers to work together on.”

The team focused on new materials for the kayak that offer lower embedded CO2, longer life and recyclability, selecting “Recyclamine” technology from Aditya Birla Advanced Materials (Mumbai, India) for the manufacturing process (learn more about this patented process). The project provided the team the opportunity to develop processing knowledge and performance testing for new sustainable materials and tools, that are said to increase composite EOL options and be deployed to future projects.

The final wild water kayak produced is of the same weight as current kayaks — 10.5 kilograms — but has reduced the minimum width from 60 centimeters to 53 centimeters after the recent rule change. Following the successful completion of the kayak, Holmes will then test in wild water conditions and ascertain whether the new reduced width affects racing performance. If this is successfully tested, the NCC says Holmes will take the new kayak into racing conditions later in the year. The project team also plan to run recycling trials with the material and generate data on the recovered fiber and matrix to give confidence in secondary uses.

“Being able to see a project through from an idea to a completed product was really rewarding,” notes Burns, who jointly led the project. “Leading the project from the technical side, I gained insight and understanding into so many areas — from tooling to material selection, through to manufacture. I feel it has also formed stronger links within the early careers community at the NCC.”

This project also enabled the testing of new processes, in order to conduct an effective life cycle analysis (LCA). Material waste and energy consumption data was collected on the manufacturing instruction sheet, as operations were executed.

This provided an invaluable opportunity for the early careers team, Kate McClearn, a graduate at the NCC explains: “I was able to learn from the difference between what I had planned and what was carried out in practice, allowing me to optimize this process for [the] future, and giving me guidance on how I can improve my manufacturing instruction writing.”

According to Hannah Swinbourne, another graduate from the project team, added, she was able to conduct an LCA covering everything from the process mapping, boundary setting and data collection, through to finding out the global warming potential values.

Related Content

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCarbon fiber/flax landing gear achieves 54% weight reduction via tailored layup optimization

Fuko’s Biogear showcases how strategic composite material distribution and natural fiber damping properties can lightweight and enhance critical aerospace structure performance.

Read MoreGenerative Orthoses project to reshape orthopedic care

CRP Technology, MHOX and Istituto Ortopedico Rizzoli, one of the winners of the WORTH Partnership Project II, have developed bespoke orthoses using generative design, Windform GT fiberglass materials and PBF.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreRead Next

NCC digital design trial speeds up composite pressure vessel proof of concept

Application of multi-disciplinary optimization (MDO) techniques determines optimal composite hydrogen pressure vessel design five times faster, says the NCC.

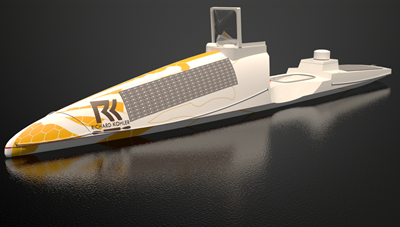

Read MoreSicomin-sponsored solo kayak crossing takes advantage of composites

Incorporation of Sicomin carbon fiber and PVC foam sandwich construction ensures an efficient kayak for extreme paddler Richard Kohler’s 6,700-kilometer journey across the South Atlantic.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More