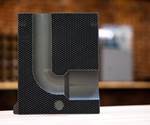

Markforged launches first FR continuous fiber-reinforced plastic for 3D printing

V-0 rated Onyx FR to open new applications in aerospace, defense and automotive

Markforged (Cambridge, Mass., U.S.), manufacturer of metal and carbon fiber 3D printers, has announced the availability of Onyx FR, a V-0 rated flame-retardant material designed for industries such as aerospace, automotive and defense. Traditional 3D-printed plastics will burn if they catch fire, but this new material is self-extinguishing, so it will actually stop itself from burning. Onyx FR features unmatched strength, superior print quality, high-quality surface finish — all while resisting fire.

Onyx FR is available with Markforged’s Industrial Series printers. Learn more through the company’s datasheet.

Onyx FR joins Markforged’s portfolio of industrial metal and composite materials, including the cloud-based software platform Eiger, designed to enable users to design and print remotely. The company recently raised $82 million expand its product line, to include investments into composites fabrication.

“Onyx FR opens up more applications for 3D printing across automotive, aerospace, and defense industries because it meets higher fire safety standards,” says Jon Reilly, VP of product at Markforged. “When these parts are reinforced with strands of continuous carbon fiber, they are as strong as aircraft-grade aluminum at half the weight.”

Related Content

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

.jpg;width=70;height=70;mode=crop)