iPul pultrusion system enhances Carbon TT’s CFRP profile production for vehicle chassis

Krauss Maffei’s subsidiary, Pultrex, delivers a customized iPul pultrusion system for the production of large profile parts for around 70,000 vehicle chassis annually.

Carbon TT composite profiles. Photo Credit: Krauss Maffei

“We’re making vehicles lighter. This will allow them to transport higher cargo loads while using less energy,” says Carbon Truck & Trailer GmbH (Carbon TT, Stade, Germany), the corporate philosophy in line with the young company’s specialization in building carbon fiber-based chassis for lightweight commercial vehicles. More recently, its use of an iPul pultrusion system for the development of lightweight, CFRP construction profiles is one primary reason behind the company’s success. The newly installed pultrusion system, delivered by Pultrex (a British Krauss Maffei subsidiary, Lawford, U.K.) and tailored to Carbon TT’s requirements, produces profile parts for around 70,000 vehicle chassis annually.

“Despite all the obstacles, we managed to deliver and commission the system on schedule,” explains Krauss Maffei Sales Expert Wolfgang Hinz. “The unpredictable political situation in the wake of Brexit, as well as the consequences and other limitations caused by COVID-19 were not foreseeable when the system was ordered in mid-2020. [However], the experience and dedication of the technicians and project managers helped in commissioning the system according to plan.”

The highly automated iPul pultrusion system is operational at Carbon TT’s Buxtehude location near Hamburg, Germany, and produces large CFRP profiles in series, which are used in high-load components for vehicles such as buses, small trucks and mobile homes. “The iPul system makes it possible for us to manufacture components in series at a consistently high level of quality. At the same time, the system gives us another selling point in multi-axial pultrusion — there are only five other systems like this one in the world,” says Gerret Kalkoffen, managing director of Carbon TT.

According to Kalkoffen, the company’s carbon fiber construction solutions help meet increasingly rigid requirements for sustainability, efficiency and safety, especially for vehicles powered by batteries and hydrogen fuel cells. “Carbon fibers provide more material advantages than just their weight,” he notes. For example, a CFRP chassis is approximately 60% lighter than comparable steel chassis; this weight reduction also lowers CO2 output and increases both the payload and the cruising range. In addition, the CFRP chassis compensates for the additional weight of batteries in electric vehicles (EVs) and effectively protects them in the event of a crash.

“Our customers are automotive OEMs with high standards. Our own standards for the technology and service of our production systems are equally high,” says Kalkoffen. “In Pultrex, we’ve found a partner with decades of experience in pultrusion. In collaboration with Krauss Maffei, they offer fast and reliable service.”

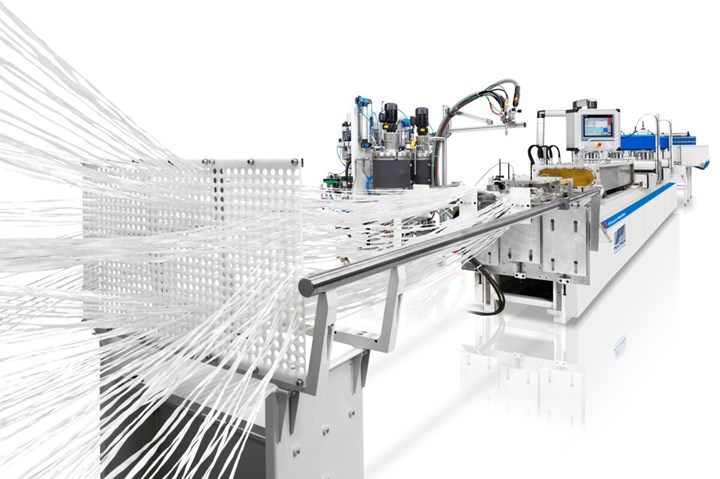

Pultrex iPul pultrusion system. Photo Credit: Krauss Maffei

It is reported that the system’s innovative gripper concept made an especially positive impression. “The grippers operate with precision and without slipping. This is a must for ensuring the consistent high quality of our complex CFRP profiles.” All system components — both for mixing and metering technology and for injection and pultrusion technology — comes from a single source. The iPul technology also enables Carbon TT to run production at a speed of up to 2.25 meters per minute at 20 tons of pulling force. For large and complex profiles, pultrusion can also be carried out at up to 40 tons in parallel operation.

Carbon TT has also developed its own roving guide for wrinkle-free reforming of multi-axial roving used on the system. The injection box makes it possible to quickly and easily impregnate the large profiles with thick walls and a high fiber volume fraction, the company says. First, the fibers are soaked in the injection box with a polyurethane matrix and then shaped into the approximate profile form. At the same time, the closed box prevents any unwelcome odors which arise during production with open baths.

The mold was adapted and designed by Carbon TT with spring-in and shrinkage taken into account for the final geometry. The profiles are trimmed down to the final dimensions automatically by the system and then processed further.

Related Content

ASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreDITF oriented rCF tapes target virgin fiber CFRP substitution

Infinity project developed highly oriented rCF/PA6 tapes with 88% the tensile strength, modulus of a virgin CFRP product and 49-66% reduction in global warming potential.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More