Dielectric properties measurement drives NDT technology to composites market

Material-Wave Interactions Laboratories is ready to put its nondestructive, in-process quality control and lab-based antennas into the market; they measure anisotropic/dielectric/magnetic material properties at high scpeeds.

Material-Wave Interactions Laboratories (MWI Lab, Tempe, AZ, US), a 2010 spin-off of non-destructive material inspection technology developed at Arizona State University (Tempe), is coming through a period of substantial research and development and is preparing to put its product into the composites fabrication and maintenance and repair market.

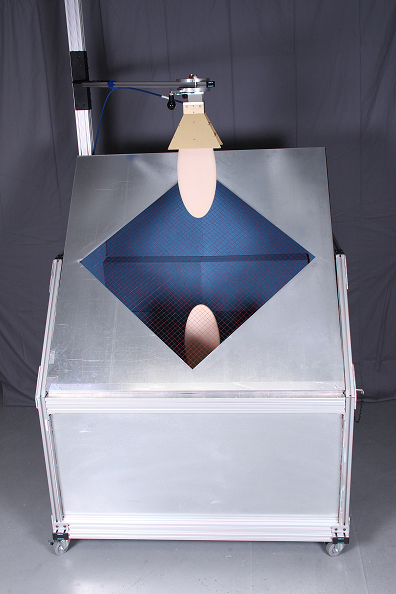

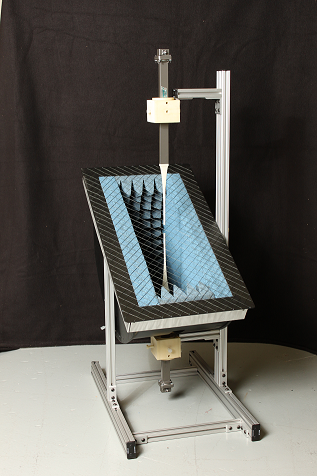

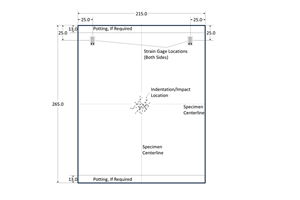

MWI Lab manufactures nondestructive, in-process quality control (QC) and laboratory quality assurance (QA) antennas and systems. Using MWI’s patented radio frequency (RF) and microwave (MW) antennas, MWI provides testing services or customized manufacturing solutions using Gaussian Beam technology. These antennas and systems are used to measure the anisotropic/dielectric/magnetic material properties in advanced composites such as honeycomb, resistive films and radome materials. This technology can detect defects such as subsurface voids, delamination, faulty repairs or RF and MW leakage in composite structures.

The technology is the brainchild of Rudy Diaz, an engineering professor at ASU, and Jeff Peebles, MWI Lab president and formerly of ASU. The two worked together in the defense aerospace industry for more than 20 years and together at Hexcel Advanced Products Division (subsequently acquired by Northrop Grumman) 10 years ago where the idea of measuring dielectric values to evaluate material properties was hatched, but limited at the time by subpar computing power. The two reconnected at ASU in the early to mid 2000s and resurrected the technology. The increase in computing power during the intervening years enabled the design of a new generation of antennas and near field sensors: the Gaussian Beam technology. The computing speeds available today enable MWI Lab’s Gaussian Beam systems to operate in real time in realistic industrial environments.

MWI Lab’s non-contact Gaussian Beam antennas have a planar-wave, broadband, narrow beam (without focus points) spot sizes and offer relatively large dynamic ranges when used in insertion loss, reflection loss, composite repair and RCS applications. Data collection and signal processing is provided by analyzers manufactured by Keysight Technologies (Santa Rosa, CA, US).

Matthew Witte, chief commercial officer at MWI Lab, says the number of potential applications of the company’s technology is broad and ranges from in-line/in-process analysis during manufacturing to prepreg manufacturing to composites maintenance and repair.

As an example of in-process analysis, Witte points to a system MWI Lab developed to assess the dielectric properties of coating on Kevlar paper that was to be used to fabricate honeycomb for a radio-sensitive composite structure. Peebles says the system, which scanned Kevlar paper roll-fed in web form through an MWI Lab scanner, identified flaws in 42% of the paper’s coating — flaws that would have rendered the honeycomb, and the composite structure in which it was used, useless.

MWI Lab has also focused on providing customers rental scanners to assess a variety of parts, particularly for aerospace applications. Customers include Boeing, Northrop Grumman, General Atomics, General Dynamics, Raytheon, GE Aviation and others. Peebles says the attraction of MWI Lab’s technology is its speed of interrogation, which can be done in as few as 2-3 minutes, compared to hours for other comparable systems. Frequency of its products range from 40 Hz to 50 GHz.

Going forward, says Witte, the company is focusing on “cradle to grave” services for all levels of composites fabrication and application. “We offer a chance to catch a flaw before it goes to market,” says Witte. This effort includes development of a handheld unit (due out by the end of 2015) for maintenance and repair applications that can provide high-speed composites surface interrogation at a variety of depths and sensitivities. Applications include aerospace and automotive parts and structures.

MWI Lab is seeking channel partners to help it move its dielectric-measuring technology into the composites marketplace. Interested parties are encouraged to contact Witte at mattwitte@mwilab.com.

Related Content

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreOptimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreRead Next

Ultrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More