Building code requirements renewed for CarbonCast wall panels

ICC-ES ESR#2953 renewal revalidates performance and compliance of AltusGroup precast wall assembly featuring C-Grid carbon fiber grid connector and rigid foam insulation.

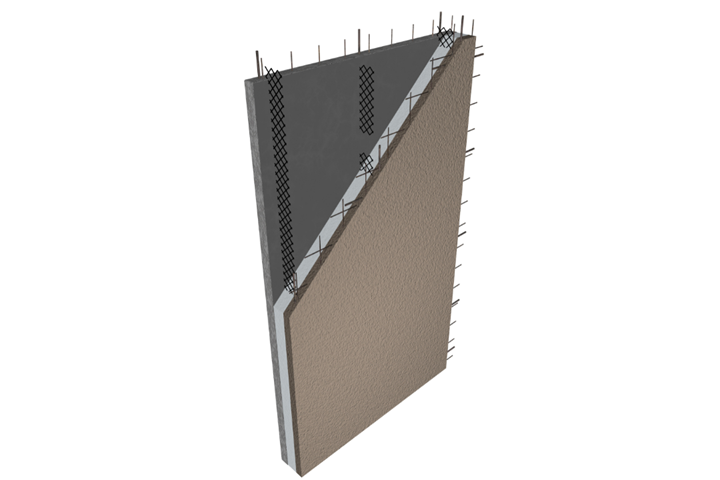

An illustrated cutaway of a CarbonCast panel, with the C-Grid (in black) integrated. Photo Credit: AltusGroup

CarbonCast high-performance insulated wall panels, manufactured by AltusGroup (Greenville, S.C., U.S.), an international collaboration of precast concrete companies across North America, have renewed their evaluation report (ESR#2953) through ICC Evaluation Service (ICC-ES, Brea, Calif., U.S.), reaffirming that the CarbonCast wall panels meet code requirements.

CarbonCast high-performance insulated wall panels with C-Grid carbon fiber-reinforcing shear truss connectors and rigid foam insulation were tested in accordance with ICC-ES Acceptance Criteria AC-422. The accepted report, ESR#2953, was first published by ICC-ES in February 2014 and has been renewed yearly.

Building officials, architects, contractors, specifiers and designers usee ICC-ES Evaluation Reports to provide a basis for using or approving products in construction projects under various ICC building codes. Many municipalities and building jurisdictions require an ICC-ESR certification before allowing use of a structural building product in their area.

ICC-ES has thoroughly examined AltusGroup’s product information, test reports, calculations, quality control methods and other factors to ensure the product is code-compliant. Testing for much of the ICC-ES criteria was completed in the accredited laboratory facilities at the University of Miami (Florida), as well as at the Constructed Facilities Laboratory of North Carolina State University (Raleigh), along with prior research and testing performed at other independent laboratories and agencies. Dozens of precast sandwich test samples were submitted by AltusGroup precasters nationwide to verify the performance of the C-Grid connector and assembly across the group’s North American manufacturing base in satisfaction of the AC-422 criteria pioneered by the AltusGroup and ICC.

In collaboration with C-Grid composite reinforcement producer partner Chomarat North America (Anderson, S.C., U.S.), the most recent report included additional testing to address carbon fiber, epoxy, supply chain and durability performance confirmation tests of the grid. According to John Carson, executive director for AltusGroup Inc. and its precast partner members in North America, the criteria and testing “remains the most significant of any wythe composite connector in the market today.”

Related Content

-

MFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.