Bombardier forms academic partnership for pan-Canadian EcoJet project

As flight testing ramps up its second phase, University of Victoria Centre for Aerospace Research (CfAR) and British Columbia’s SME Quaternion Aerospace will help explore the blended wing body aircraft configuration and new technologies to reduce business jets emission by up to 50%.

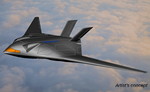

An EcoJet prototype is out for testing with the Bombardier engineering team. Source: Guillaume Plisson/Bombardier

Aircraft manufacturing company Bombardier (Montreal, Canada) has unveiled the first of many academic collaborations on its pan-Canadian and sustainability-focused EcoJet flight testing research project. One such collaboration is with Bombardier’s long-standing partnership with the University of Victoria Centre for Aerospace Research (CfAR) and British Columbia’s SME Quaternion Aerospace, in a shared vision of the positive role innovation plays in the sustainable transformation of the Canadian aerospace industry.

The multi-year EcoJet research project that debuted around 15 years ago kicked off its first phase of flight testing in 2017 with 8-foot-span prototypes and is now leveraging a flight vehicle more than twice as large. Bombardier’s expertise as a business aircraft OEM and of the CfAR and Quaternion Aerospace with scale vehicles strengthen the innovation capacities of all parties while fostering new knowledge about the next generation of more sustainable aircraft. CfAR does offer composites manufacturing services, so advanced materials may play some role as this project accelerates.

“Now that we have publicly disclosed some aspects of the first phases of the EcoJet flight testing program, it is important for us to give credit and to share the response with our partners who are instrumental to this dimension of the research project,” says Stephen McCullough, senior vice president of engineering and product development, Bombardier. “Collaboration between local businesses and top academic institutions is key in nurturing a strong and thriving Canadian aerospace industry. Our hand-in-hand work with the University of Victoria is a meaningful example of such innovation pathway that stimulates coast-to-coast skill transfer and talent development.’’

Moreover, according to Afzal Suleman, Canada Research chair, director and professor, Centre for Aerospace Research, University of Victoria. “Through this collaboration, our students and researchers are gaining critical real-world skills while helping to push forward the frontiers of sustainability and redefining the boundaries of what is possible for the future of the global aviation industry.”

Piloted by Bombardier, the collaborative work on the design and fabrication of the EcoJet flight test vehicles involves multidisciplinary teams, consisting of Québec-based Bombardier engineers and technicians, along with BC researchers, engineers and students.

All flight campaigns on blended wing body (BWB) scale test vehicles, which have been exploring the prototypes’ behavior in free flight and perfecting their radically different flight control laws, are the fruit of this collaboration.

Related Content

-

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.