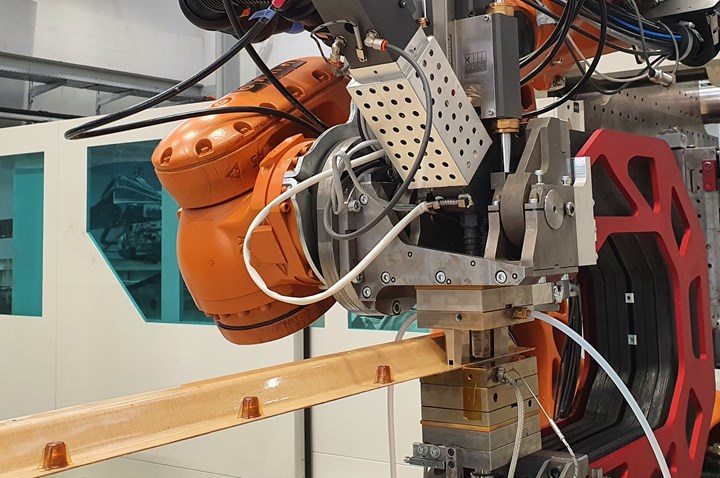

Functionalized PEI profiles made using CCM. Anybrid worked with REHAU Innovation Group to demonstrate use of its ROBIN robotized injection molding system to overmold Böllhoff Hitsert metal inserts into Xelis glass fiber/PEI omega profiles made using its CCM process, aimed toward possible aerospace applications. Photo Credit for all images: Anybrid

As global industries and markets demand increased sustainability, novel automated systems such as Anybrid’s (Dresden, Germany) robotized injection molding (ROBIN) offer a means to functionalize composite components, eliminating bonding and facilitating lightweight assemblies.

“We developed this robotized injection molding machine in 2019 to produce hybrid components,” says Michael Stegelmann, managing partner at Anybrid (see “Robotic injection molding for functionalize composites”). “Hybrid components” refers to functionalizing a structure with an injection molded polymer to create local attachment points, stiffening ribs, etc. This overmolding process has gained traction in composites, but typically uses a traditional injection molding machine.

Anybrid has miniaturized the process to fit within a robot arm end effector, enabling, for example, pultrusions to be overmolded inline or molded structures to be functionalized within a robotic cell. Anybrid has recently completed a series of demonstrations to highlight new capabilities its technology can offer including:

- Overmolding joining/fastening inserts with compression-molded polyamide (PA) composite profiles and polyetherimide (PEI) composite stringers made using continuous compression molding (CCM);

- Combining 3D printing and overmolding;

- Hybridization with new processes and materials such as reactive thermoplastic pultrusion and wood polymer composites.

Functionalized profiles for auto, aero

“The use of composite materials in structural applications creates specific challenges for joining,” explains Stegelmann. “ROBIN can be added to production lines to integrate inserts that enable attachments and facilitate assembly [Fig. 1]. Anybrid has demonstrated this in two projects with the Innovation Group of REHAU Industries [Rehau, Germany]. REHAU produces polymer-based solutions for construction, automotive and industrial applications including window profiles and components for car exteriors, bumpers and air duct systems. REHAU is also researching a variety of innovations using composites, including natural fiber and bio-based composites.”

Dr. Ahmad Al-Sheyyab, manager of the Composites Technologies Department of REHAU Innovation Group, notes, “Our mission is to check every idea for relevance and make what sometimes seems impossible possible.”

As explained on the REHAU Germany website, when Dr. Stephan Sell, research chemist in Al-Sheyyab’s team, first saw Anybrid’s ROBIN technology at the K trade fair in 2019, he could see many opportunities for it at REHAU. “They have succeeded in transforming the otherwise stationary injection molding machine into a mobile machine that can be moved freely in space,” says Sell. “This means that functional elements such as seals, metallic inserts, connecting elements or ribs can be retrofitted to existing molded parts, profiles, semi-finished products and metal hybrid composites.”

Fig. 1. Functionalized automotive profiles. Anybrid worked with REHAU Innovation Group to integrate threaded inserts into GF/PA6 profiles by overmolding with GF/PA6 compound, including functionalization such as anti-twist features (top). The small size of the mold enables ROBIN to reach in between the walls on the rear side of the omega profile (bottom).

In 2021, Al-Sheyyab and his team began an extensive study with Anybrid on thermoplastic extrusions, composite profiles and molded parts. By late 2022, they had successfully overmolded profiles offline but also integrated a ROBIN unit into a production line at the REHAU technical center, where profiles were overmolded in-situ.

The expertise of both teams was important in these developments. “The parameters from extrusion have to be brought together with those from injection molding,” says Sell. “It is important to match the speed of the production line to that of the part to be overmolded. For example, the cooling time of the overmolded element must be taken into account.”

For automotive applications, demonstrations used Lanxess Bond-Laminates (Brilon, Germany) Tepex 102-RG600 PA6 with 47% glass fiber roving for compression molding. Resulting composite profiles were then overmolded using Lanxess’ (Cologne, Germany) PA6 flame-retardant Durethan BKV60 and BKV30 with 60% and 30% chopped glass fiber, respectively. For this application, ROBIN was used to integrate threaded fasteners from Böllhoff (Bielefeld, Germany) into a narrow omega-shaped profile (Fig. 1).

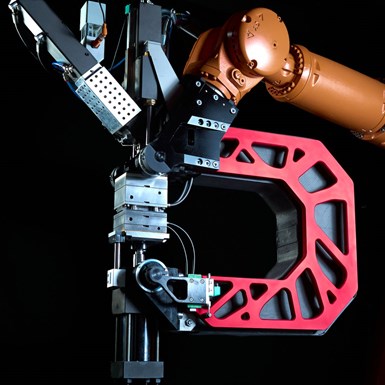

Stegelmann explains the steps involved: “First, we position the metal insert inside the small injection mold within the ROBIN machine [Fig. 2]. Next, the ROBIN system is aligned with the profile, and then the mold is closed and the fastener is overmolded. Because the mold is very small, ROBIN is able to reach even between the high walls on the back side of this profile and overmold fasteners with anti-twist resistance or integrated sealing, for example.”

In a second set of demonstrations, the teams used continuous glass fiber/PEI profiles produced by Xelis (Bermatingen, Germany) using its CCM process. Similar to omega-shaped stringers used in commercial aviation, Hitsert threaded inserts from Böllhoff were integrated via overmolding with glass fiber/PEI materials fom SABIC (Riyadh, Saudi Arabia). “These parts demonstrated our ability to overmold using high-temperature materials approved for aerospace,” notes Stegelmann.

“We see great potential to use Anybrid’s mobile injection molding in a variety of continuous process lines,” says Sell, “such as thermoplastic extrusion, pultrusion or CCM, for the production of composites parts for transport or industrial applications, for example. It enables monomaterial systems — products that consist of the same polymer matrix. Steps such as gluing are eliminated. This makes production faster and the products easier to repair or recycle.”

Fig. 2. Inserts aid assembly. A metal insert can be placed inside the mold (red circle, top) and then ROBIN is positioned over the profile, the mold is closed and the insert overmolded. Such functionalized profiles enable quick assemblies, such as this shell demonstrator using ULTEM PEI composite profiles with integrated aviation-certified Böllhoff inserts.

He notes that ROBIN also saves costs. “Using the small injection molding robot makes it possible to dispense with large, expensive tools. The logistical effort is also reduced since profiles no longer have to be moved to injection molding machines. We have shown that costs can be reduced and productivity and flexibility increased in our extrusion lines.”

“Mobile injection molding allows us to apply recurring elements as needed with a high degree of flexibility to profiles or large-scale components,” says Stegelmann. He points out a shell demonstrator (Fig. 2), “where we show that with overmolded omega profiles, you can achieve a very quick, simple construction to achieve light-weight, high-strength assemblies.” REHAU and Anybrid plan to continue development, looking at processes beyond extrusion and joining technologies for composite parts.

Combining 3D printing and overmolding

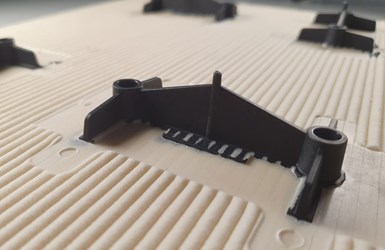

To demonstrate the ability to functionalize 3D-printed parts, Anybrid worked with the Institute of Lightweight Engineering and Polymer Technology (ILK) at Technische Universität Dresden in Germany. “The use of large-scale/large-format additive manufacturing [LSAM/LFAM] is growing,” notes Stegelmann. “The technology has been proven to be quite capable and cost-effective, but the problem with these big machines is they can print with high deposition rates but not with high resolution, and thus, fine details are impossible. This is where we can help, because ROBIN can overmold detailed functional elements during the print process.”

Fig. 3. Overmolding and 3D printing. Anybrid demonstrated ROBIN’s ability to overmold GF/PP features onto a cellulose fiber/PLA panel made by a large-format 3D printer.

Anybrid and ILK performed demonstrations using the 8 × 2 × 2-meter-high “Supertooler” LFAM developed and built in-house at ILK onto an eight-axis Kuka Robotics (Augsburg, Germany) system. Materials included bio-based polylactic acid (PLA) reinforced with cellulose fibers supplied by UPM Biocomposites’ (Helsinki, Finland) UPM Formi (Lahti, Finland) division. The printed structure was then overmolded using polypropylene (PP) with 30% glass fiber supplied by Mitsui Chemicals (Tokyo, Japan). “The black PP compound allowed us to see the material flow onto the 3D-printed PLA substructure,” says Stegelmann. “We quickly preheated the 3D-printed surface using an infrared heater and then closed the ROBIN mold onto the panel, thermoforming the part surface. This thermoforming is needed due to the large bead size of the printed materials.”

Although the print bead is constant for each print, it could be 4-24 millimeters wide and 1-5 millimeters tall. That rough surface creates issues with achieving a good seal for the ROBIN mold and runout of the injection material during overmolding. “Thermoforming provides a smooth surface, and we also achieve a good connection between the overmolding and substrate materials,” says Stegelmann (Fig. 3).

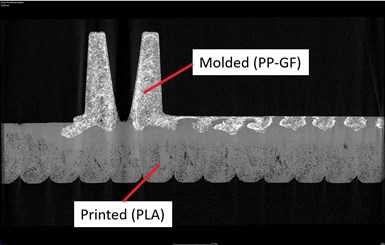

Computed tomography (CT) scan of overmolding on 3D-printed panels showing diffusion and interlocking of polymer systems.

This connection was investigated using computed tomography (CT). “We can clearly see diffusion between the two polymer systems, which creates a mechanical interlocking,” says Stegelmann. “There are still some challenges in optimizing the processing temperatures, but we see a real opportunity for in-situ functionalization of 3D-printed parts with local inserts, sealings, clips, etc. Our next step is to demonstrate this potential with a technical component from the marine industry. We can see a future where large-volume 3D printing facilities will be equipped with our mobile injection molding system as standard due to the possibilities it opens for their parts.”

Novel processes, materials

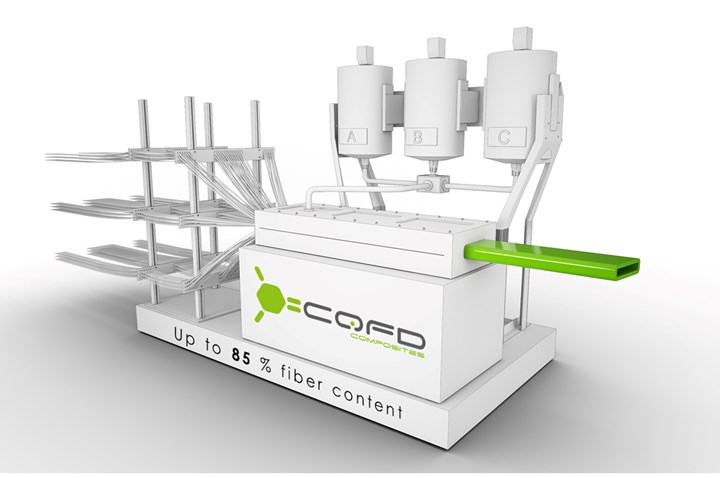

Although Anybrid works with a wide range of standard materials, the innovative nature of the technology makes it attractive for companies developing new materials and processes. One such partner is CQFD Composites (Mulhouse, France), a supplier of structural thermoplastic composite profiles. Founded in 2006, CQFD Composites has developed a reactive thermoplastic pultrusion system. This technology uses in-situ polymerization of low-viscosity caprolactam monomer to produce, in this case, PA6 pultruded profiles with high glass fiber content, up to 85% by weight.

Branding these materials as Supercore, CQFD claims other advantages, including a modulus of 50-62 gigapascals — roughly 1.5 times more stiffness than conventional glass fiber composite profiles — and a density of 2.0 grams/cubic centimeter. CQFD profiles made using unidirectional (UD) glass fibers (GF) offer a higher specific rigidity versus profiles made using aluminum (2.7 grams/cubic centimeter). Also, because these profiles are thermoplastic composite, they can be thermoformed, reshaped and overmolded.

Fig. 4. Hybridizing reactive thermoplastic composite pultrusion. Anybrid demonstrated ROBIN’s ability to overmold onto high-fiber-content (up to 85% by weight) GF/PA6 panels (bottom) made by CQFD using its reactive thermoplastic pultrusion process (top). Photo Credit (top): CQFD

“We wanted to demonstrate a process chain where CQFD’s reactive pultrusion process could be combined with our robotized injection molding inline,” says Stegelmann. The first demonstration used CQFD’s in-house GF/PA6 profiles and a black-tinted PA compound with 30% glass fiber supplied by Lanxess for overmolding. The overmolded feature (Fig. 4) is a shape Anybrid created to demonstrate the complexity that is possible with ROBIN. It also provides a good basis to test for adhesion between the overmolding and the substrate.

“Due to the innovative composition of CQFD’s composite materials and the right process parameters, it is now possible to obtain excellent adhesion with the overmolded PA6 inserts even when using a highly fiber-filled composite,” says Frank Chauzu, founder and CEO at CQFD. “Supercore profiles are also available with compatibility for other material combinations such as PP. To reach that compatibility, the profiles go through a specific treatment developed by CQFD that promotes adhesion between the PA6 and PP materials.”

Stegelmann notes the tests with CQFD produced a monomaterial system with excellent adhesion. Overmolding was also demonstrated using Mitsui Chemicals’ PP material. “I was surprised by the great adhesion quality of the first trials using PP,” says Stegelmann.

Stegelmann and Chauzu also emphasize that it is possible to use the process heat during reactive pultrusion instead of preheating the profile for overmolding, as is typically necessary. This would enable even better process and energy efficiency, they explain. “For example, a PA composite might be heated to 180 to 200°C,” says Stegelmann, “instead of allowing the profile to cool, we can overmold as the pultrusion exits the system to achieve a good connection, saving time and process steps. Again, overmolding is not new, we are just enabling it to become directly part of the process line, but with increased flexibility and lower cost.”

Chauzu adds, “Due to the great flexibility of the Anybrid technology, the combination with our thermoplastic pultrusion leads to many interesting applications to develop together.”

In a separate trial, Anybrid was able to demonstrate the potential for ROBIN in combination with a new type of sustainable bio-based material. “We met Dongnam Realize [Daejeon, South Korea] when they won the JEC startup competition at last year’s composites show in Paris,” says Stegelmann. “Their CXP material uses a cellulose-based polymer made from waste wood products.” The Dongnam Realize website notes that cellulose cross-linked polymer (CXP) can be made from sawdust, wood chips, discarded vegetables and even invasive species like certain reeds and water hyacinth, for example.

Anybrid overmolded panels made of the natural composite wood (cellulose fibers in lignin matrix) with cellulose cross-linked polymer (CXP) from JEC award winner Dongnam Realize.

“Dongnam sent us some of their pelletized materials and we did overmolding tests using ROBIN,” says Stegelmann. “The materials processed really well and create a whole new possibility of generating functionalized biocomposites for furniture or consumer goods that eliminate the need for petroleum-based plastics. We see a lot of potential for using ROBIN with these cellulose polymers in the future.”

The opportunity for Anybrid’s ROBIN technology to produce a variety of more sustainable composite parts seems, if not limitless, then at least very broad. “The issue is convincing companies to move beyond the known and familiar,” says Stegelmann. “Overmolding has been well proven and is gaining use in composites. We are just making that process mobile and more flexible to provide really futuristic solutions that can generate value for manufacturers now.”

Related Content

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreBraided thermoplastic composite H2 tanks with co-consolidated molded boss areas to fit EV battery space

BRYSON project demonstrates possible designs, automated manufacturing and low permeability concepts, including EVOH liner and novel PPA matrix.

Read MoreComposites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.

Read MoreRead Next

Novel processes for hybrid thermoset-thermoplastic pultruded parts

CFRP pultrusion and pullwinding specialist Epsilon Composite combines thermoplastic overmolding with traditional thermoset processes, demonstrated through aircraft struts and industrial applications.

Read MoreThe democratization of composites is reconfiguring supply chains

New robotic and digital technologies are enabling advanced in-house capabilities for small companies and innovative suppliers willing to embrace the move toward more affordable, sustainable composites.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More