JEC World 2019: Kordsa

Kordsa has, in a just a few short years, transformed itself into a major supplier in the composites supply chain.

Kordsa (Istanbul, Turkey) has, in a just a few short years, transformed itself into a major supplier in the composites supply chain, and at JEC World 2019 it occupied a large, highly visible stand. Kordsa CEO Ali Caliskan sat down with CW and outlined his company’s goals. First, however, Caliskan noted that Kordsa is part of a larger organization that has a long history in the tire reinforcements business. In 2014, in an effort to diversify, the company expanded into composites, focusing on the manufacture of honeycomb cores, fabrics, prepregs and other fiber-based reinforcements. Since then, Kordsa has worked hard to establish a presence not just in Europe, but North America as well. “We are seeking balance between the market in North America and in Europe,” Caliskan said. “And we look for synergies to exchange information between the two.”

To that end, Kordsa in February acquired U.K.-based Advanced Honeycomb Technologies and, in late 2018, U.S.-based Fabric Development Inc. (FDI) and Textile Products Inc. (TPI). Going forward, Caliskan says Kordsa has plans to expand into composites fabrication operations, either via organic or acquisition growth. “We continue to search for companies that are a good fit for the Kordsa strategy,” he says.

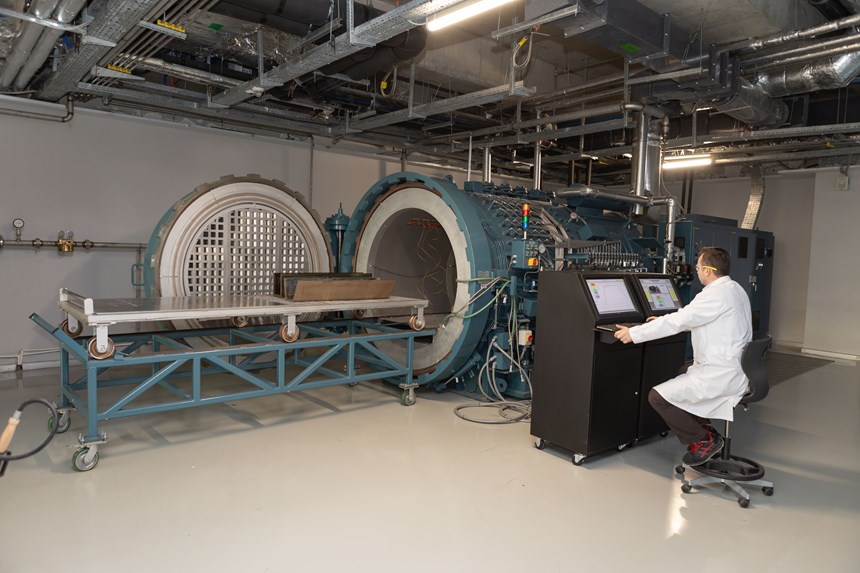

Kordsa is building a technical center in Turkey that will offer fiber placement, autoclave, testing, prototyping and additive manufacturing services. In addition, the company is working on its own automated fiber and tape placement technology. Caliskan also said the company is looking at establishing similar technical centers in the U.S. and Europe.

“We want to grow in this industry,” Caliskan said. “We are making a second Kordsa that might, in a decade, be larger than our tire business.”

Related Content

-

TCR Composites introduces TR1116 snap-cure epoxy prepreg resin system

Designed for press-cure applications, the resin system is highlighted for its snap-cure capability and tailored properties.

-

Prepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

-

Aerospace prepregs with braided reinforcement demonstrate improved production rates, cost

A recent time study compares the layup of a wing spar using prepreg with A&P’s TX-45 continuous braided reinforcement versus traditional twill woven prepreg.