JEC World 2019: Center for Composites Materials, University of Delaware

The Center for Composite Materials (CCM) at the University of Delaware introduced at JEC a new fiber-based product called TuFF (Tailored Universal Feedstock for Forming).

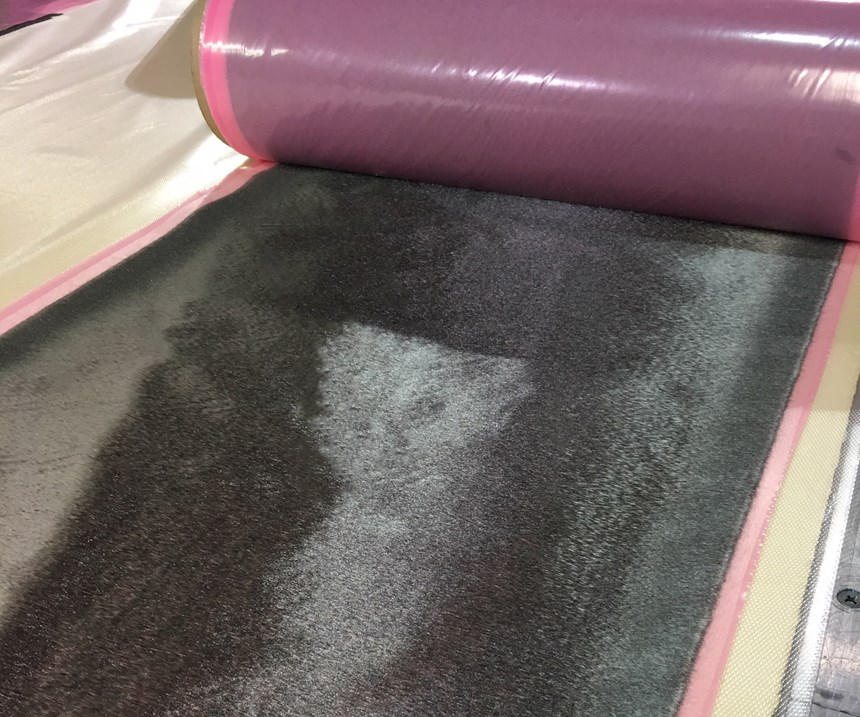

The Center for Composite Materials (CCM) at the University of Delaware (Newark, Del., U.S.) introduced at JEC a new fiber-based product called TuFF (Tailored Universal Feedstock for Forming), which is designed to integrate short fibers (particularly those from recyclate) into a 20-inch-wide unidirectional (UD) sheet. The novelty of TuFF is that CCM has developed a process whereby 95 percent of the short fibers in this UD material are aligned within ±5 degrees. John Tierney, senior scientist at CCM, says TuFF can integrate any fiber type with any resin type, but admits that most of CCM’s work has focused on use of carbon fibers and polyetherimide (PEI) resin. Features of the material include fiber volume fraction of 63 percent, equivalent properties compared to continuous IM7/8552 (well-known Hexcel carbon fiber/epoxy prepreg), 40 percent biaxial in-plane stretch, and easy and fast formability (~1 minute). Thin-ply formats are available, as are dry preforms and consolidated blanks, all in a variety of areal weights.

Parts on the CCM stand at JEC (see photo), made via rapid vacuum-forming, showed that TuFF offers good, homogenous stretching with minimal perimeter pulling or separation of material. “It behaves like metal in terms of material and processing,” says Tierney, adding that the material is adaptable for automated fiber and steered tape placement as well as material source for 3D printing/additive manufacturing. In addition, he notes that the use of thermoplastic resins makes TuFF easily recyclable. The team will present a number of papers on this new material technology at the upcoming SAMPE conference in Charlotte with TuFF materials on display in booth N42. The research that led to the development of TuFF was funded by the U.S. Defense Advanced Research Projects Agency (DARPA).

Related Content

-

Prepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

![CCM University of Delaware, 250-gsm quasi-isotropic [0°/90°/45°/-45°] laminate made with highly aligned 3-mm carbon fiber](https://d2n4wb9orp1vta.cloudfront.net/cms/brand/CW/2019-CW/cw-19-blog-jec-ccm-tuff-closeup.jpg;width=860)