JEC World 2019: Boston Materials

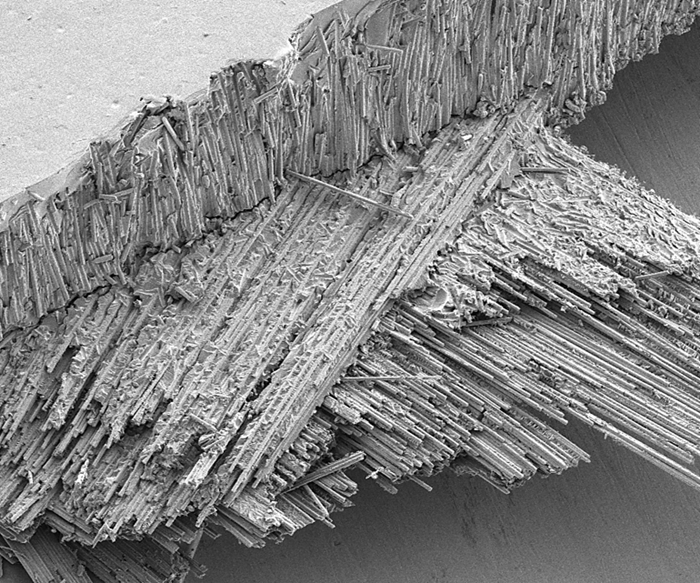

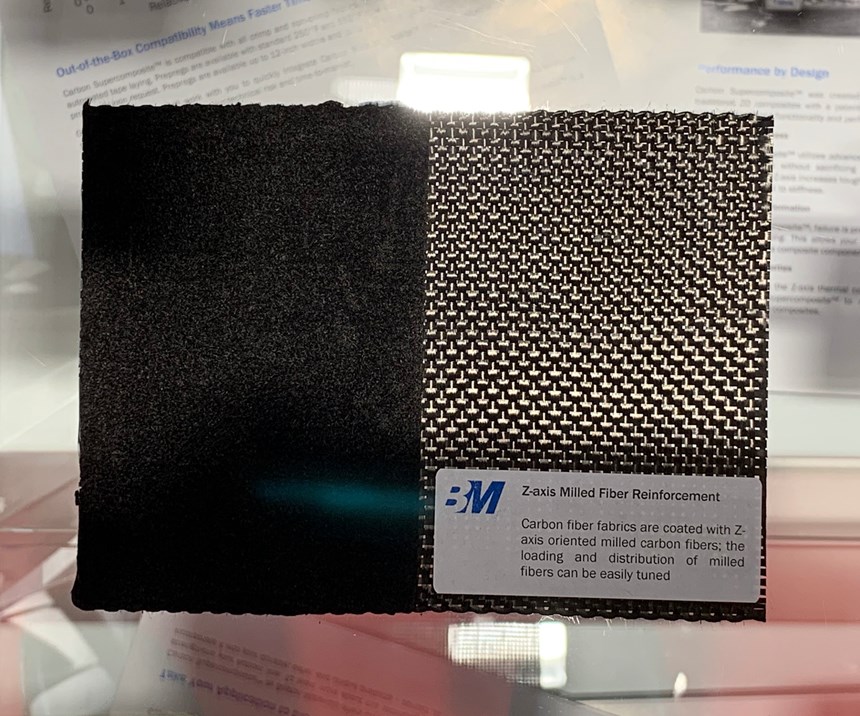

Boston Materials announced its Carbon Supercomposite, a carbon fiber fabric that features milled carbon fibers magnetically aligned in the “z” direction to provide uncommon ply-to-ply strength.

Boston Materials (Bedford, Mass., U.S.) announced at JEC World 2019 the development of its Carbon Supercomposite, a carbon fiber fabric that features milled carbon fibers magnetically aligned in the “z” direction to provide uncommon ply-to-ply strength. Although Boston Materials is working with Sabic (Pittsfield, Mass., U.S.) to integrate Carbon Supercomposite with polyetherimide (PEI) and polycarbonate (PC), the fabric, says the company, is resin agnostic and compatible with any thermoset or thermoplastic resin matrix. Anvesh Gurijala, founder and CEO of Boston Materials, says Carbon Supercomposite can increase compressive toughness by as much as 300 percent and compressive strength by 35 percent compared to traditional prepreg systems. He said the company is initially targeting sporting goods and overmolding applications, but the material clearly has potential in a variety of end markets.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.