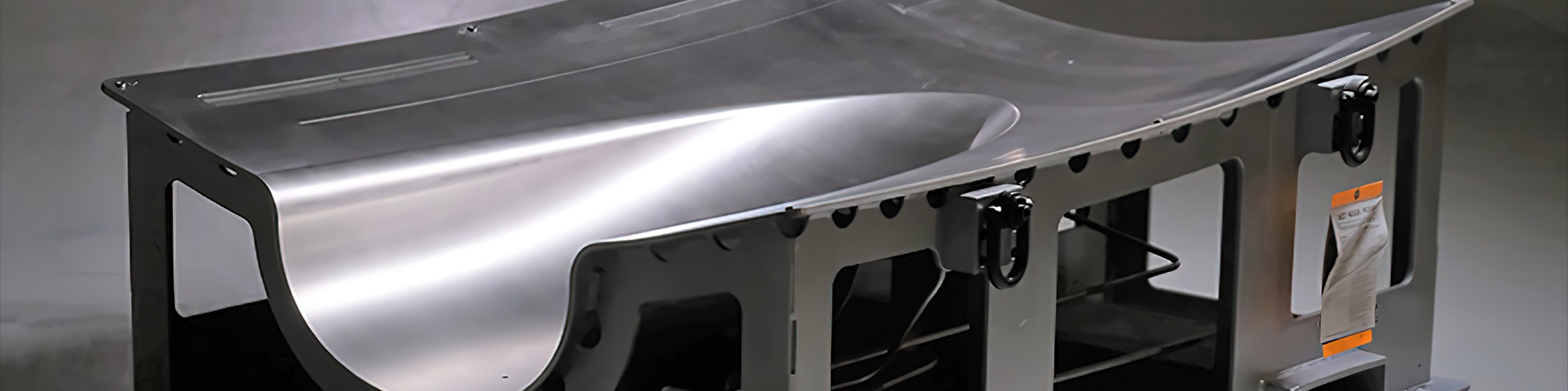

Lincoln Electric Additive Solutions has recently delivered its first aerospace tool with the facesheet 3D printed in Invar. Although the design of the tool has been described as “traditional,” by additively manufacturing the cure surface from Invar instead of machining a block or plate of the alloy, the manufacturing process was simplified and cycle time was reduced. Photo credit all images: Lincoln Electric Additive Solutions.

As the use of composites has soared in commercial aircraft in the last decade, so too has the size of parts being converted from metals to composites — mostly to carbon fiber-reinforced epoxy prepreg. That has made it more challenging to find tooling options that can be produced in large sizes relatively affordably and quickly.

One challenge is that typical carbon fiber composite prepreg has a very low coefficient of (linear) thermal expansion (CLTE or CTE). As composite aerostructure parts get larger, so too must the tools in which they’re formed. However, if a tool material has a higher CLTE than the material being molded in it, then final part dimensions can deviate unacceptably from specifications. In tools with trapped/undercut features, the cured part could actually break during cooling and/or demolding, or could become die-locked in the tool.

Consequently, prototype and low-volume production tools for traditional composite aerostructure parts have typically been fabricated from hand layup/autoclave-cured carbon fiber/epoxy prepreg itself, with higher volume production tools typically machined from blocks or plates of Invar, a nickel-iron alloy renowned for its low CLTE. Both tool materials are expensive and can have long lead times, which has caused many in the industry to seek alternatives in large-format additive manufacturing (LFAM).

As reported in the CW December 2020 issue (see Learn More), one option that’s been tried is to 3D print a thermoplastic composite core and then apply conventional carbon fiber/epoxy tooling prepreg facesheets to the core. This entire assembly is then autoclave cured together (without need for adhesives) to produce a tool. While this approach may prove viable to mold prototype and low-volume production parts, high-production volumes still require a more durable option. That option is now available in the form of mold facesheets and backing structures fabricated with 3D-printed Invar.

Gas-metal arc welding

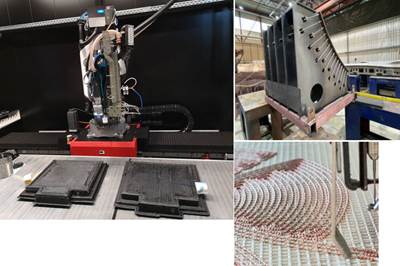

Presently, there are several printing technologies for both small- and large-format metal additive manufacturing. Some systems use laser-fused metal powders, with or without a binder (which must be flashed off in a post-print bake cycle). Another technology option is wire-arc additive manufacturing (WAAM). Generally, WAAM systems combine metal (in wire form), a gas-metal arc welding (GMAW) power source mounted on an industrial robot, and a numerically controlled (NC) multi-axis positioner on which the build takes place.

Unlike powder-metal AM technologies, WAAM permits a much larger build area, offers much faster deposition rates (5-10 pounds/2.3-4.5 kilograms per hour) and, overall, uses less expensive material. Versus machining plates/blocks of metal or castings, WAAM can reduce lead times from months to weeks, helping manufacturers bring parts to market faster. It also significantly increases design freedom and part-consolidation opportunities. For example, rather than machining a facesheet and then building a separate backing structure for an aerostructure tool, the entire tool with integral backing structure can be printed in a single build with less waste/scrap. Additionally, the ability to print lattice structures can lead to lighter printed tools, which makes them easier to ship and store, and improves thermal properties, reducing autoclave heat-up/cool-down cycles.

Currently, WAAM’s biggest limitations are the physical reach of the robots used and the size of the room that encloses the printing cell in which the build takes place. On the other hand, this cell does not need to be in a cleanroom, as with many metal AM processes. The only room requirements are an air handling system to collect fumes and localized shielding of the gas source.

One of the few design constraints on WAAM prints is the reach of the robot and its associated wire-arc welding arm. That can be overcome by printing smaller sections and then welding them together post-printing, prior to machining to clean up the molding surface. In this image, the Wisk cure tool with integral backing structure was printed in Invar in two sections, which were then welded together prior to machining the facesheet to achieve an acceptable surface (top). After machining, the tool was checked for surface finish (bottom). By printing smaller sections and welding them together, total printing and production time for the tool are reduced.

As with 3D-printed plastic parts or tools, WAAM produces a near-net shape part or tool whose surface is striated and bumpy (in this case, from the weld beads). Thus, post-print machining of the molding surface is needed to bring WAAM-fabricated tools into dimensional compliance.

Supply integration

Several companies sell large-format WAAM systems, although very few offer printing services. One of the latter is the Additive Solutions unit of Lincoln Electric Co. (Cleveland, Ohio, U.S.), which offers custom WAAM printing services using the company’s own GMAW-based WAAM technology on 20 machines at its 75,000-square-foot/6,968-square-meter facility in Cleveland, Ohio, U.S. Post-process machining of 3D-printed components is conducted at its Baker Industries

(Macomb, Mich., U.S.) subsidiary, which provides tool engineering and fabrication services for automotive and aerospace markets, plus custom-machining services.

Lincoln Electric is a long-time supplier of welding and cutting equipment, automation and consumables such as welding wire in various tool steel, stainless, nickel, bronze and aluminum alloys. Reportedly, the company has been exploring metal AM for more than a decade. Lincoln Additive Solutions launched in 2019 and began printing with Invar wire in 2020. Metal additive manufacturing has long been used to prototype parts and to repair or replace legacy parts, but now — with the addition of Invar wire — it also can be used to produce aerospace tooling.

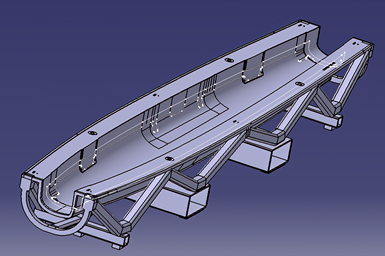

Boeing and Lincoln collaborated to design and 3D print an aerospace composite cure tool (above) that integrated the entire backing structure as well as the facesheet into the printing process, expanding the technology’s capability. After printing, the tool was finish machined at Baker Aerospace (below) prior to functional testing at Boeing’s St. Louis, Mo., U.S., facility to document dimensional stability, surface roughness and vacuum integrity.

“What’s different about Lincoln Electric is that we’re in control of the entire process, from start to finish, since we manufacture power sources, welding equipment, flexible automation [robots and positioners], post-print subtractive processes [machining] and our own wire feedstock,” explains Mike Wangelin, business development/sales manager for Lincoln’s Additive Solutions. “Not only do we have decades of experience in welding and advanced automation, but we also own and develop our own additive software, which not only sections a 3D model into layers to generate the deposition path, but also programs the robot and positioner. Our SculptPrint operating system was originally developed to drive complex 5-axis NC machining and has since been adapted to AM. Since we own the software, as more is learned about the WAAM process and efficiencies are gained, immediate updates are made. Backed by the power of our large parent corporation, we’re able to invest in each advanced technology segment along the way to drive the whole WAAM process forward.”

Lincoln’s current WAAM systems have a build space of 4 x 6 x 6 feet/1.2 x 1.8 x 1.8 meters, although Wangelin says that is expandable as needed. “Basically, right now the system can print in a 5-foot cube (0.14 cubic meters), but that’s part dependent,” he explains. “If it’s a narrower part, print volume is increased up to 9 feet [2.7 meters] long. We’re only limited by the robot’s reach, so we could easily use a larger robot or pedestal to raise the robot up, if needed, to extend our current build envelope. We’ve been working on a couple of projects that are 10 feet [3.1 meters] long and vertically printing 4- to 5-foot [1.2- to 1.5-meter] segments and welding them together after printing. Printing shorter segments and then joining them not only extends the effective reach, but it also shortens tool build times.”

Proof is in the printing

Lincoln reports that it has already produced and delivered its first WAAM Invar tool to an aerospace customer. While the production tool is described as “traditional in design,” by 3D printing its facesheet in Invar, Wangelin says the fabrication process was simplified significantly and overall cycle time was reduced. Lincoln also delivered several carbon-steel production tools to aerospace customers in 2020.

Currently, Lincoln is collaborating with The Boeing Co. (Seattle, Wash., U.S.) on a project focused on incorporating an Invar backing structure into the 3D print to produce a fully integral 3D-printed tool for a composite part on an aerospace program under development at Wisk Aero LLC (Mountain View, Calif., U.S.). Wisk, which is backed by Boeing and Kitty Hawk Corp. (Mountain View, Calif., U.S.), is developing commercial aircraft for the urban air mobility (UAM) market.

“Boeing continues to be an industry leader in additive manufacturing technology development and integration, but we also acknowledge the need for tool engineering’s philosophy to evolve because traditional tool design hasn’t capitalized on newer technical capabilities,” explains Melissa Orme, Boeing Additive Manufacturing vice president. “We recognized the technical expertise of Lincoln Electric and their commitment to rapidly advancing wire-feed additive manufacturing technology by collaborating with them on the Wisk project.”

Teams from Boeing Research & Technology and Boeing Additive Manufacturing proposed the development of a composite cure tool that pushed the envelope of WAAM technology to the next level and provided design optimization support to help Lincoln develop the fully 3D-printed Invar composite cure tool.

“Tooling is the last item needed before a production run, so there’s always schedule pressure to produce tools as quickly and affordably as possible,” adds Wangelin. “As aerostructure parts become more complex, and tooling lead times and costs start to come down because of AM, Lincoln Additive Solutions can offer a real advantage by cutting production and delivery times — especially for complex tools. Add to that our focus on design for additive collaboration and our work in topology optimization, and we have something that will be of great interest to aerospace customers.”

“The Boeing and Lincoln Electric collaboration to advance state-of-the-art WAAM technology is a revolutionary achievement and a testament to both companies’ commitment to innovative technology development,” adds Michael Matlack, Boeing associate technical fellow. After finish machining at Baker Aerospace, the WAAM cure tool will undergo functional testing at Boeing’s St. Louis, Mo., U.S., facility to document dimensional stability, surface roughness and vacuum integrity.

Related Content

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MorePlant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreRead Next

3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More

.jpg;width=70;height=70;mode=crop)