CAMX 2018 preview: Parabeam

Parabeam BV (Helmond, The Netherlands), part of Canadian ZCL Composites Inc., is featuring its Paraglass and Paratank 3D E-glass and hybrid fabrics, as well as its Hssue fiberglass sandwich system.

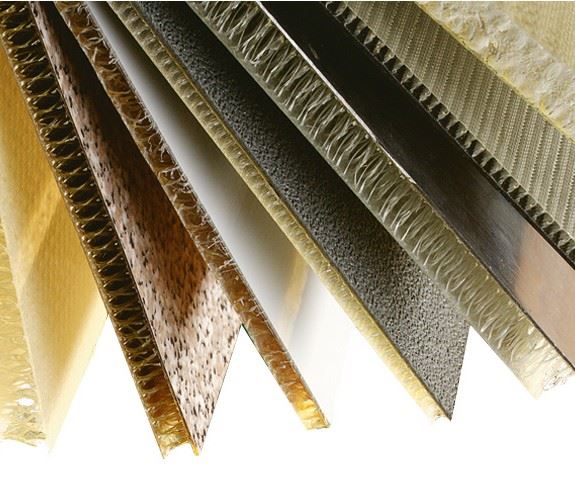

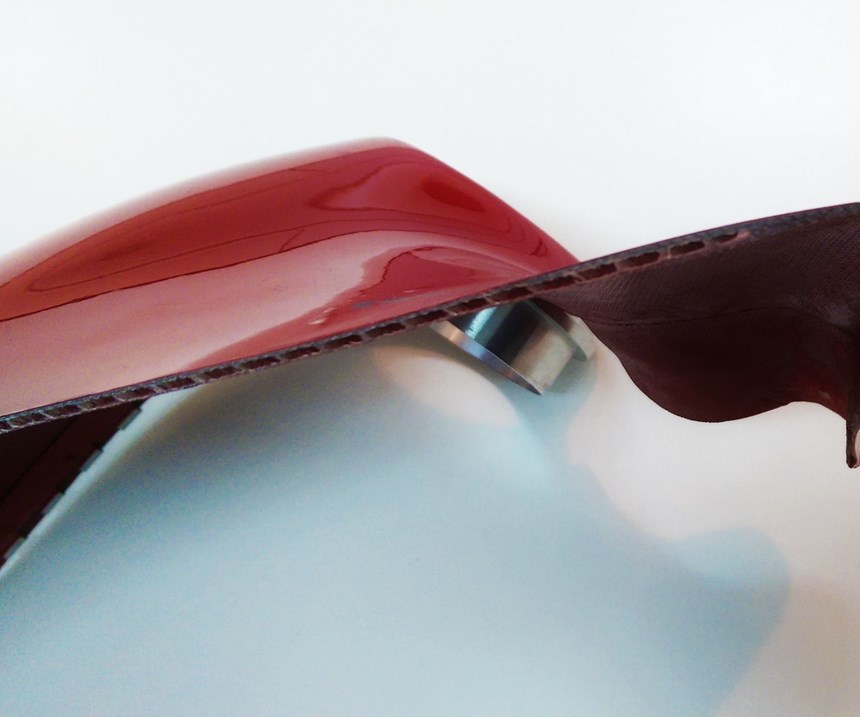

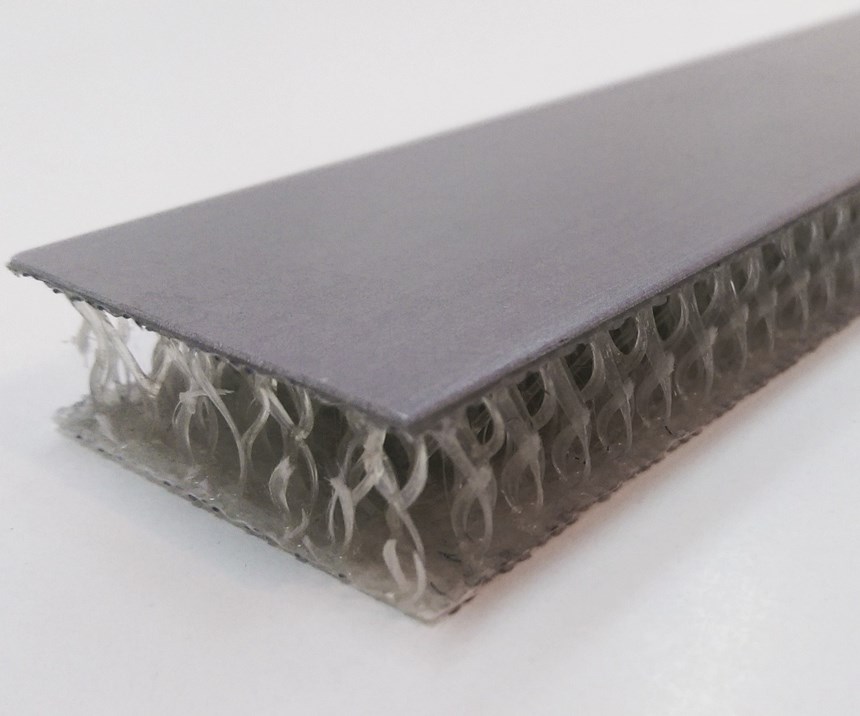

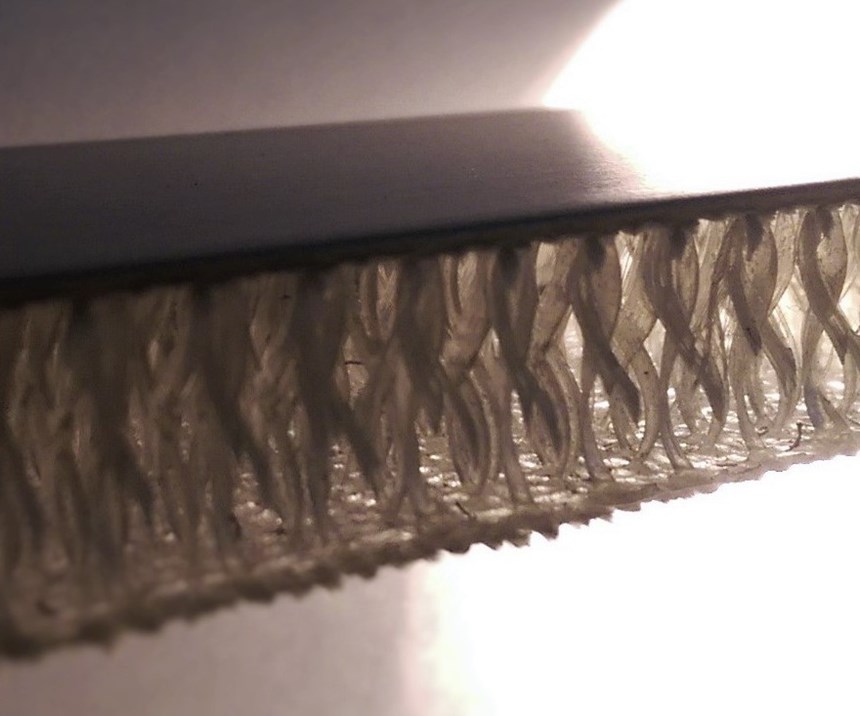

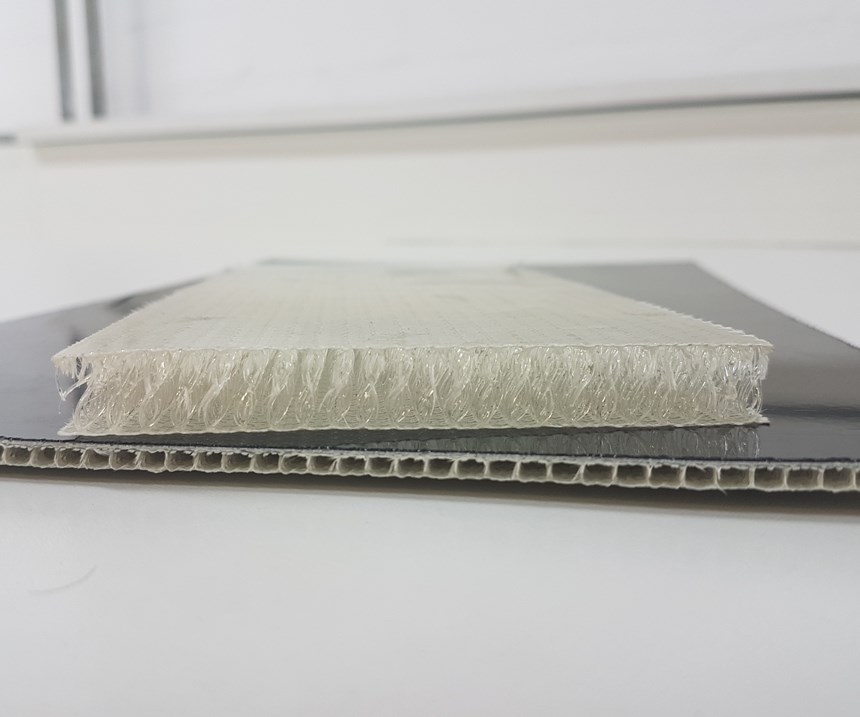

Parabeam BV (Helmond, The Netherlands), part of Canadian ZCL Composites Inc., is featuring its Paraglass and Paratank 3D E-glass and hybrid fabrics, as well as its Hssue fiberglass sandwich system. Parabeam says its products are targeted toward core applications in end markets that rely on factors such as weight, impact resistance, thermal insulation, acoustic damping or strength. Parabeam’s fabrics, combined with phenolic resin, reportedly meet performance standards like BS 6853, NFP 92501 (values M1 and F0) and EN 45545-2. Combined with polyurethane resin, the laminate becomes permanently flexible and offers significant durability. Parabeam also notes that its fabrics can be combined with foam epoxy to create lightweight panels. Standard sandwich thickness ranges from 0.118 to 0.866 inch; custom thicknesses are also available. Noted applications for Parabeam’s materials include tank liners, aircraft interiors, prop blades, public transport interiors, cladding and walls for construction, or marine superstructures. Booth J30.

Related Content

-

Repurposed carbon fiber waste support closed-loop recycling goals

CAMX 2025: Work with Carbon Fiber Conversions, a supplier and a strategic partner, to transform carbon fiber waste into a valuable resource, strengthening both business and sustainability credentials.

-

Maximize your experience: CAMX 2025 exhibit previews, Part 1

This list of 90+ exhibitor previews solicited by CW offers a glimpse into the various technologies, emerging trends and solutions attendees should look for on the CAMX show floor.

-

The future is composite: Innovation, resilience and human experience

CAMX 2025 showcased the power of collaboration and purposeful innovation, a clear reminder that the composites industry is all about human potential.