CAMX 2018 preview: Norplex-Micarta

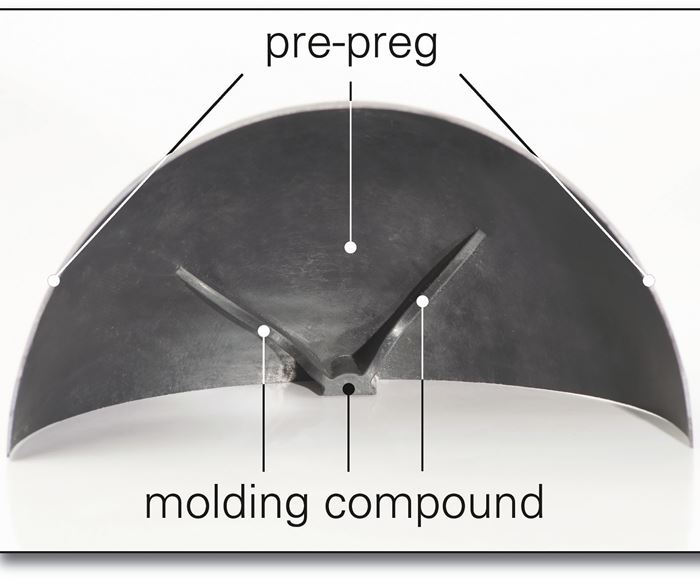

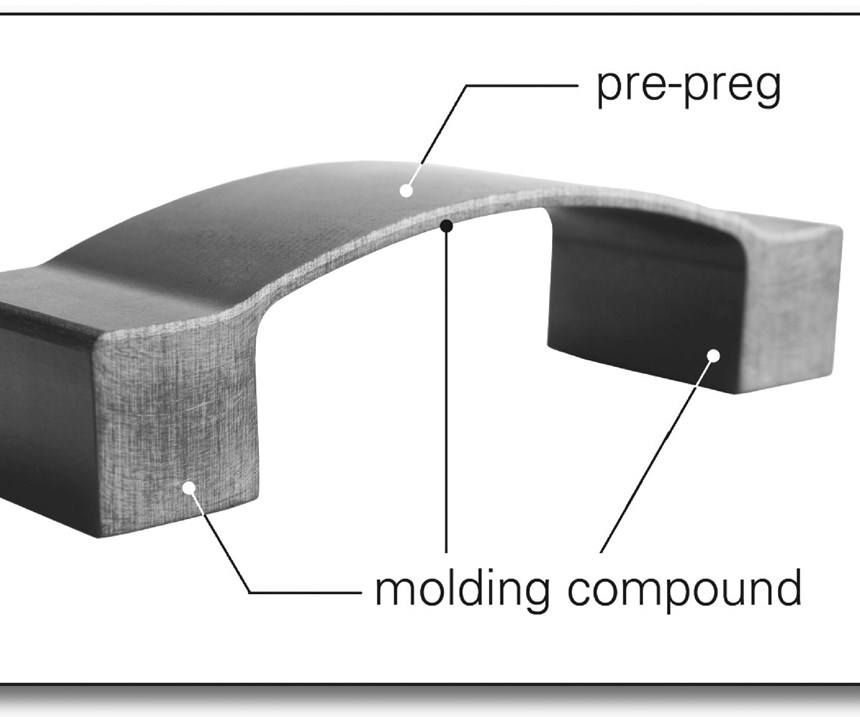

Norplex-Micarta (Postville, IA, US) is featuring its recently introduced EnableX, a continuous fiber prepreg that can be co-cured in a multimaterial molding system to produce near net shapes.

Norplex-Micarta (Postville, IA, US) is featuring its recently introduced EnableX, a continuous fiber prepreg that can be co-cured in a multimaterial molding system to produce near net shapes. EnableX materials are specifically designed for compression molding and tested by Norplex-Micarta to ensure compatibility with the process. In addition, Norplex-Micarta’s in-house laboratory and development capabilities allow for new concepts to be prototyped, or datasets to be developed to support specific design criteria. EnableX has been verified on several epoxy and phenolic resin systems, with more in development. Reinforcement options include natural fibers such as cotton or paper, carbon fiber, glass fibers and fibers that significantly alter the behavior of the material such as PTFE or thermoplastics.

Related Content

-

Clean Sky 2 outer wing box demonstrator validates OOA LRI, shimless assembly and SHM

Full-scale wing box project achieves TRL 5 with 2% weight reduction and 4% reduction in recurring production costs through improved manufacturing efficiency and assembly processes.

-

Induction heating system enables OOA composites processing

JEC World 2025: Roctool focuses attendees’ attention on the light induction tooling (LIT) system targeting efficiency, sustainability and performance.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.