AVANCO: Driving the industrialization of CFRP structures

The AVANCO Group is producing high-quality CFRP parts into a wide array of applications from six production facilities in Germany and the US.

I recently received a press release about the company INOMETA and a new carbon fiber reinforced polymer (CFRP) bridge adapter it has introduced to enable high-quality, high-speed printing without the need for expensive hydraulic clamping systems. Look for it in our upcoming Nov issue. Visiting the INOMETA website, I was surprised that they are part of a larger entity, the AVANCO Group, which also includes Xperion, now renamed Xelis, and filament winding specialist Dynexa (Laudenbach, Germany). I knew the name Xperion, having written a 2010 Inside Manufacturing article about its Continuous Compression Molding (CCM) process, used to make a variety of continuous fiber-reinforced thermoplastic composites, including glass fiber/polypropylene bed springs and CF/polyetherimide fixation rail assemblies used to attach Airbus A330/A340 interior sidewall panels.

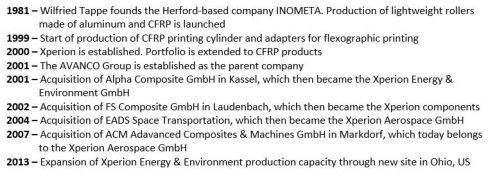

So what is the history for this family of companies? INOMETA head of development Christian Göhner replied with the timeline below.

I asked if there are synergies between the companies. “At each location we are focusing on different markets and have different production capabilities, like hand lay-up, prepreg, RTM, filament winding, automated fiber placement, press molding and pultrusion,” Göhner responds. “Depending on the complexity and level of automation we can choose each available production technology in our group.” He adds that the design and development teams for each location are strongly connected, allowing AVANCO to identify and offer the most economical solution to each customer and project. The companies can manufacture in batch or serial production, and tout the largest winding machine in the world, for example, building structures up to 3 m (9.8 ft) in diameter and over 23 m (75.4 ft) in length.

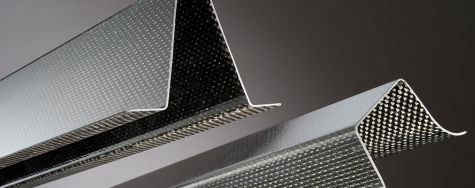

Thermoplastic profiles like these are used as sidewall and ceiling panel attachment rails in Airbus and Boeing aircraft. SOURCE: Xperion, now Xelis.

The companies span a wide range of product expertise via six production facilities in Germany and the US:

Advanced Roller & Profiles — composite rollers and profiles for industrial applications, including the entire spectrum of rotating elements for the film, paper, printing and packaging industry.

Composite High Pressure Systems — composite CNG pressure tanks for natural gas-powered applications.

Composite Components — mechanical engineering structures such as tensile or pressure struts, structures, levers, beams or shafts, as well as parts for machine tool fabrication and drive technology like drive shafts for automotive and marine applications.

Composite Ventures — a range of aerospace structures including thermoplastic composite clips and rails, as well as satellite parts and substrates for satellite solar generators.

AVANCO does produce structures using aluminum and steel, but it focuses mainly on its expertise in CFRP, and that mostly in industrial applications. I asked why CFRP is being used in industrial rollers. Göhner explains that the demand for bigger rolls and higher running speeds in production machines is constantly increasing, to where steel or aluminum rollers can’t meet the requirements for stiffness, density, inertia and critical speed. “The only solution is CFRP with its high specific stiffness, low density and high damping,” he says. “The properties of fibers are also continuously improving, so we can achieve even lower deflection and higher critical speeds in the future, which furthers the efficiency and quality of production machines.”

The AVANCO Group produces filament wound tubulars that span a wide range of diameters, including up to the world’s largest, at 3m and 23m in length. SOURCE: AVANCO Group

Göhner says most of INOMETA’s and Dynexa’s products are made using filament winding. INOMETA’s CFRP doctor bar is an example of the company’s engineering and manufacturing prowess. INOMETA can design the natural frequencies out of the range of excitation and compensate the thermal expansion in axial direction down to zero.

This gantry milling bridge uses CFRP to meet needed accuracy and acceleration requirements. SOURCE: The AVANCO Group.

Some examples of the AVANCO Group's impressive industrial CFRP applications include this gantry milling bridge installed at an German shipyard. "With an overall width of more than 12 meters and the needed accuracy and high accelerations, CFRP was the only possibility to fulfill the costumer’s demands," says Göhner. "The total weight including spindle and drives is only 3,000 kg." The composite-coupling below is produced by compression molding in an automated process, and provides a fatigue-resistant connection for a marine drive-shaft.

Compression molded CFRP coupling for marine drive-shaft. SOURCE: The AVANCO Group.

INOMETA has also developed expertise in technical coatings. "With our thermal spray technology," Göhner explains, "we manufacture functional surfaces like extreme abrasion resistance, electrical insulation or conductivity, non-stick or specific roughness by using polymer, ceramic, metal or hard metal coatings."

As I said, look in the Nov CW for the Application story on INOMETA's new CFRP bridge adapter, and hopefully even more in-depth information on some of AVANCO's other intriquing CFRP industrial structures in 2016.

Related Content

Syensqo, Teijin Carbon achieve aerospace qualification for composite resin

Resin infusion system Prism EP2400 achieves NCAMP qualification with Teijin Carbon’s advanced NCF and UD reinforcements.

Read MoreCOMPINNOV TP2 project promotes use of thermoplastics in aerospace

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreAM method enables tool-free, energy-efficient thermoset composites production

University researchers highlight how the combination of a thermally curable resin system with photothermal curing eliminates the post-curing steps involved in discontinuous, continuous fiber parts fabrication.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More