3D-printed fixtures & jigs

Holding fixtures, jigs, trim tools and metal-forming dies can be expensive elements of post-mold composite part processing and assembly. Additive manufacturing, therefore, is proving especially useful in reducing the design/build time/cost in this area.

Holding fixtures, jigs, trim tools and metal-forming dies can be expensive elements of post-mold composite part processing and assembly. Designing and building such tools can be an expensive and time-consuming part of the production process in its own right. Additive manufacturing, therefore, is proving especially useful in this area.

One application is in the post-mold trimming of similar but not identical series-molded parts. Aurora Flight Sciences (Manassas, VA, US), for example, recently produced a series of female bulkhead tools, 3D-printed in polycarbonate, for a UAV demonstrator.

“We’ve pulled about six parts from the bulkhead tools so far,” says project engineer Dan Cottrell. David Dahl, an application engineer for AM supplier Stratasys (Eden Prairie, MN, US), explains that AM enabled successful production of the bulkhead parts: “Traditional metal tools typically are designed with scribe lines machined into the surface that transfer to the composite parts, and guide post-cure trimming operations. But you can’t really print a scribe line on an AM tool.” Because each bulkhead is shaped slightly differently, parts made on the same tool end up with different dimensions because they’re trimmed uniquely. Cottrell says that to save time during trimming and finishing, Stratasys simply printed lightweight trim tools (router templates) for each bulkhead version, in a matter of a few days, to expedite the trimming process (see photo, at left). “We were able to generate an entire tooling family, very economically,” he adds.

Mike Vander Wel, head of equipment and tool engineering for Boeing Commercial Airplanes (Seattle, WA, US), describes another application: the use of AM to build a drill jig for an older aircraft part. Because legacy aircraft — US Air Force tankers, for example — were built before digital engineering tools were available, it can be time consuming to develop a mold, or holding fixture, for a replacement part.

“If we had made this drill jig in metal, it would have cost at least $50,000,” he says. Instead, the part that required replacement was laser scanned, which captured the part dimensions in a CAD file that could be easily transferred to the 3D printer. A holding jig was then 3D-printed using a low-cost plastic polymer within a few days. The jig enabled support and fast drilling of the metal replacement part. “This is a great example of how we can justify the cost of placing and using 3D printers in our facilities in a matter of months,” adds Vander Wel.

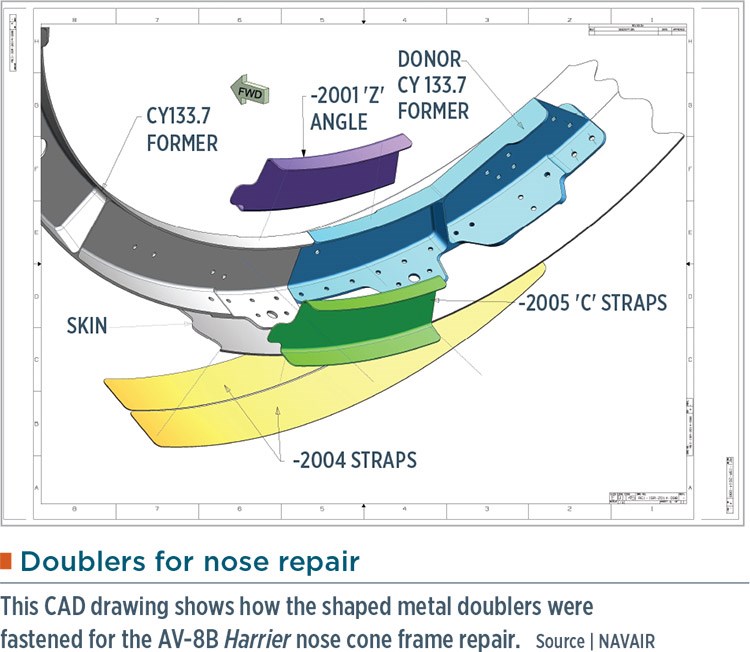

Robert “Yogi” Kestler, Science & Technology (S&T) lead; Robert Thompson, a materials engineer; and Douglas Greenwood, an aerospace engineer, at FRC East (Cherry Point, NC, US), the maintenance, repair and overhaul center for all US Navy and Marine Corps vertical-lift aircraft, tell of a set of 3D-printed fixtures used to repair a damaged AV-8B Harrier jet, which lost its front landing gear during a flight from the aircraft carrier USS Bataan. To safely land, the pilot had to descend vertically and place the aircraft’s nose cone onto a padded cradle, which substituted for the inoperative gear. All went well until the last moment, when the plane bounced, damaging an internal metal frame within the nose. After damage assessment, repair planning and structural analysis, Kestler’s group received the CAD solid model of the frame on a Wednesday, began 3D printing the next day, and on Friday, tooling blocks were complete.

Greenwood explains that the AM blocks, made in polycarbonate on FRC East’s Stratasys Fortus 400mc and 900mc AM machines, enabled forming of stainless steel Z- and L-shaped metal doublers that were subsequently mechanically fastened, on board the ship, to splice a new portion of the frame that replaced the damaged portion of the frame (see images, at left). “The combination of the CAD solid model geometry and software, our tool designers, our AM machines and a dedicated workforce enabled a one-week total turnaround of the parts needed for this repair, which is pretty remarkable.”

This short article is a sidebar to a longer feature article titled "A growing trend: 3D printing of aerospace tooling" and a companion to another sidebar titled "Additive manufacturing in automotive applications." (To read either, click on its title under "Editor's Picks.")

Related Content

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreRead Next

A growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

Read MoreAdditive manufacturing in automotive applications

Although they have been overshadowed by aerospace applications, 3D-printed tools also are finding a place in automotive processing. Here's one example.

Read MoreRobotic computed laminography brings X-ray CT resolution to large composite structures

Omni NDE collaborative robots, X-ray end effectors and Voxray’s reconstruction approach enables 5-micron inspection of aerospace parts without size constraints.

Read More