CAMX 2021 exhibit preview: Ensinger

Ensinger offers a wide portfolio of products and services for thermoplastic composites, including its Tecatec materials range and polymer pulverizing and development services.

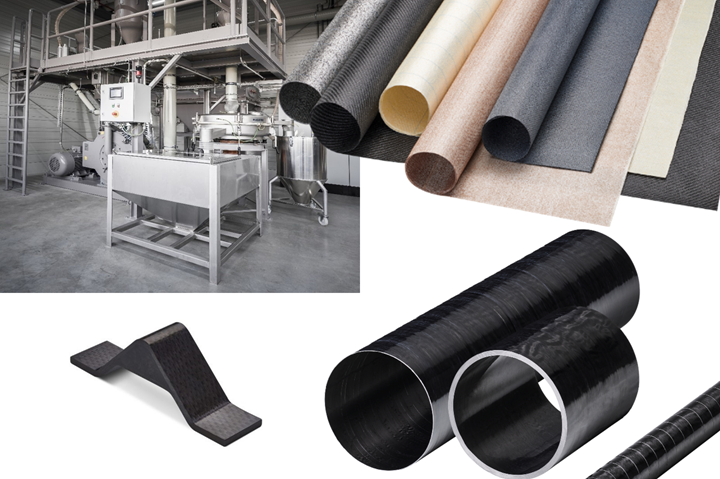

Powder pulverizing machine (top left), Tecatec CP fabric-based semipregs (top right), composite parts (bottom left) and composite tubes (bottom right). Photo Credit: Ensinger

With more than 50 years of experience in the field of thermoplastic materials, Ensinger (Bensalem, Penn., U.S. and Cham, Germany) offers a wide portfolio of products and services for thermoplastic composites and other high-end composite solutions. This includes Tecatec CP fabric-based semipregs, Tecatec IP fabric-based prepregs, Tecatec OS organosheet, powder pulverizing service, composite plates, tubes and parts.

Ensinger’s Tecatec CP single-layer semipregs are made from carbon or glass fiber fabrics coated with a thermoplastic matrix. The suitable matrix materials range from engineering polymers such as polycarbonate and polyamides, to high-performance plastics such as PEI, PEEK and PEKK. Alongside stock materials, Ensinger’s in-house compounding allows it to address most customer requests.

The portfolio also covers Tecatec IP thermoplastic prepreg materials. These are fully impregnated and consolidated, single-layer plies made from carbon or glass fiber fabrics. The full range of matrix polymers are available. Ensinger also offers customized matrix and fiber combinations, fiber architectures or matrix materials on request.

As a result of the addition of a double-belt press machine, Ensinger now offers a full in-house solution, from granulate polymer to fully consolidated, multi-layer composite laminates. Tecatec OS organosheets consist of several layers of prepreg or semipreg material, which are stacked according to the customer’s specification and then consolidated to form a laminated organosheet with a thickness of up to 5 mm. The organosheets, offered on coils or as plates, can be used for thermoformed parts or for the straightforward manufacture of thicker parts.

Ensinger’s recent investment in a polymer pulverizing machine compliant to the ATEX safety directive, delivers what the company claims is a cost-competitive advantage to customers through pulverizing polymers to tight tolerance powders. A polymer pulverizing service is also made available to customers.

Ensinger’s thermoplastic composite plates are available as carbon fiber-reinforced PEEK for medical applications, glass fiber-reinforced PEI and carbon fiber-reinforced PC and PPS as standard. Other material and fiber combinations, types of fabric or customized layer structures can be produced on request. Similarly, composite tubes are made with glass or carbon fiber reinforcement and a selection of thermoplastic matrix materials for industries such as oil and gas, sports and leisure or industrial applications. Composite tubes can be manufactured with smooth inside, outside or both, and with different fiber angles.

In addition to this product portfolio, Ensinger’s Germany-based facility is equipped with state-of-the-art technology and facilities, and retains a team of specialists for customer service and technical support. Design and engineering experience in development and manufacturing of parts made from thermoplastic composites for a wide range of industries is also available. Development services include layup design, material selection, mechanical simulation, prototype manufacturing, dimensional and mechanical testing.

Related Content

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.