More efficient reusable vacuum bags

SWORL Inc. is featuring new accessory products to facilitate bag production, vacuum sealing, removal and reinstallation of its reusable vacuum bags.

Source | SWORL

SWORL Inc. (Hutto, Texas, U.S.) introduces new accessory products to facilitate bag production, vacuum sealing, removal and reinstallation of its spray-applied, reusable silicone vacuum bags.

The company’s vacuum bags are said to cut labor costs as much as 80% while improving part quality, consistency and weight. In addition, the reusable bags are thinner, lighter weight and more tear-resistant than single-use bags, SWORL says.

To produce further handling efficiency for operations with traditional tooling, SWORL has developed several new products:

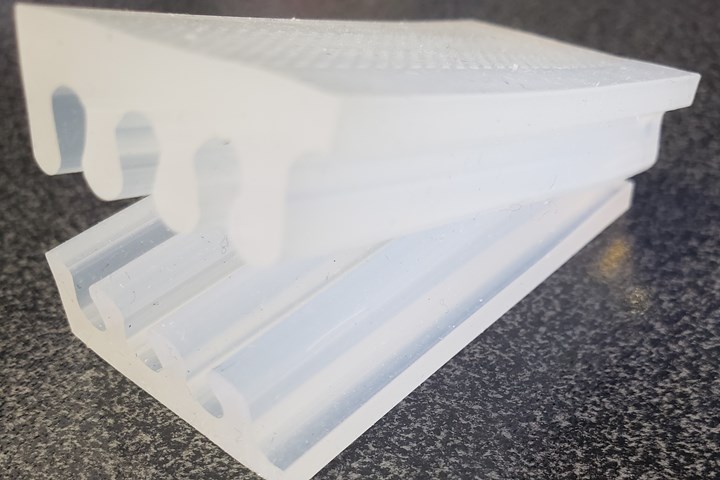

The ZSeal Profile is designed to securely seal reusable bags to the planar, flat geometries of flanges on legacy tooling. SWORL says this new product overcomes the obstacle of sealing its multi-use vacuum bags on tooling that was built without a V-groove. Each ZSeal profile is designed to interlock and form the vacuum seal. The bottom profile is bonded and cured to the flange, and then the upper profile is installed onto the bottom and bonded to the underside of the SWORL bag membrane.

SWORL Adhesive Tape is formulated to bond the reusable bag membrane to itself as well as to aluminum, composite and laminate surfaces. It oven-cures after one hour at 300ºF/149ºC.

SWORL Bonder Adhesive is said to be ideal for attaching Zseal profiles as well as injection or vacuum ports to silicone bags.

The SWORL Membrane Lifting Eye has been developed for easier handling of large, deep-draw SWORL membranes such as those built for wind turbine spinner caps, deep stand-up consoles or marine hulls. The lifting eyes can handle up to 1200 lbs of weight.

SWORL says its reusable vacuum bags are ultra-high strength products with superior tear strength at a thickness of 0.125 in. (3.0. mm). They reportedly eliminate the need for fabric reinforcement, peel ply, spiral wrap and other materials each time a part is infused, and the bags can typically be used to fabricate up to several hundred parts for many industries before requiring replacement. The bags are easy to spray-fabricate from economical dispensing equipment.

Related Content

-

ASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

-

Airbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

-

Composites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.

.jpg;width=70;height=70;mode=crop)