CAMX 2020 exhibit preview: DH Sutherland

DH Sutherland is introducing technologies for chemical application and the manufacture of protective armor.

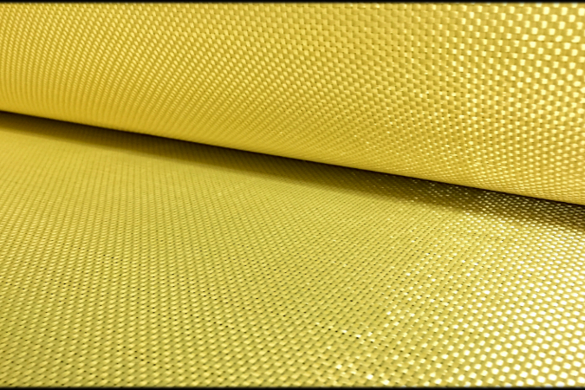

TPERxX prepreg for protective armor applications. Source | DH Sutherland

DH Sutherland (Beaverton, Ore., U.S.) is introducing technologies for chemical application and the manufacture of protective armor.

T-Link is a novel, dry prepreg system consisting of woven para-aramid fibers and a thermoplastic epoxy matrix. T-Link is said to enable armor manufacturers to improve scale and co-processability with other ballistic materials such as UHMW-PE.

According to the company, DH Sutherland and its partners developed T-Link to fill a need for dry prepreg reinforcement that is drapable, does not require refrigeration or special handling and that can be quickly consolidated into a composite structure. In the resultant T-Link dry prepreg system, DH Sutherland says, the coating is applied directly to a para-aramid tow. When delivered in a fiber, the weaving capability and size offerings are broad and determined by the weaver’s creel width. The technology is said to be ideal for armor manufacturers producing ballistic armor for applications in land vehicles, helicopters, maritime and personal protection applications.

KleanVak. Source | DH Sutherland

In the field of chemical application, KleanVak technology can be used both for mold preparation of composite parts and for solvent cleaning. The machine is said to significantly increase the speed of application, while controlling the amount of chemical applied and simultaneously removing harmful volatile organic compounds (VOC) from the working environment.

KleanVak machine applies a thin layer of solvent onto the surface of the tool or part to be cleaned, while simultaneously vacuuming and safely containing any VOCs. The VOCs are then sent through an activated charcoal filter before the air is recycled. KleanVak is also said to improve process efficiency by increasing mold utilization to reduce mold prep waiting time by up to 80%, enabling a single person doing solvent cleaning to cover more area in a shorter amount of time. In addition, KleanVak is said to enhance worker safety through both the capturing and filtering of VOCs as well as by enabling safe distancing between workers.

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

.jpg;width=70;height=70;mode=crop)