CAMX 2019 exhibit preview: IKONICS Advanced Material Solutions

IKONICS AMS will offer a presention on “Machining Methods for Perforating Composites,” during CAMX 2019.

IKONICS Advanced Material Solutions (Duluth, Minn., U.S.) is well-known in the aerospace field for its non-traditional machining method, Precision Abrasive Machining (PAM). The company is also branching into a variety of new areas such as designing customized patterns for prosthetic limb enhancement, emergency vehicle interiors, fenders, steel screen replacement and more.

IKONICS AMS will offer a presentation on “Machining Methods for Perforating Composites,” during CAMX 2019. Wes Barton, senior application and sales Specialist for IKONICS AMS will cover such topics as:

- Composite Growth in Aerospace

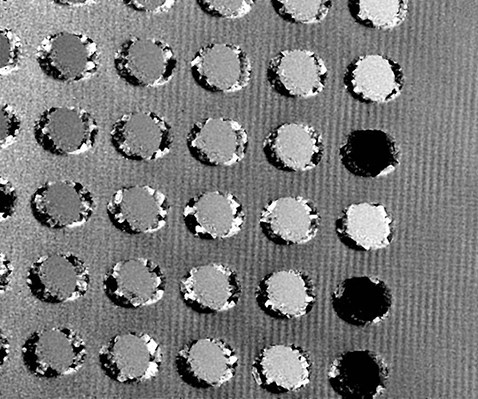

- Typical Perforated Expectations & Traditional Perforating Limitations

- Perforating Methods

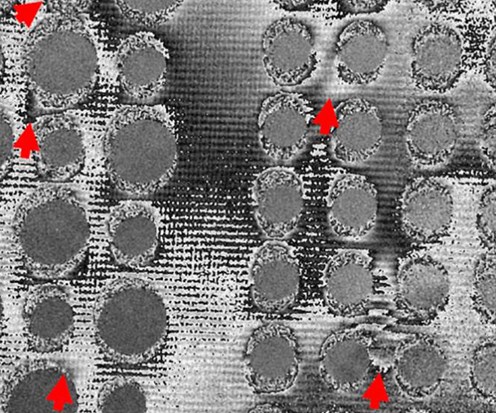

- Precision Abrasive Machining (PAM)

- PAM Process vs. Traditional Machining Methods

- PAM Applications

Related Content

-

Exacting chemistry streamlines composite surface prep

CAMX 2025: Hawkeye Industries exhibits Duratec, Styrosafe, Styroshield and Aqua-Buff brands for optimal composites coating, compounds and polish solutions options.

-

Concentrated smooth dispersion simplifies electrical conductivity applications

CAMX 2024: Total Resin presents Total Nanotüp, a concentrated dispersion of carbon nanotubes in a bifunctional reactive monomer for polyester, vinyl ester, melamine and acrylic resins.

-

Fall events chart the course for composites

A busy fall brings industry-leading events and recognition for operations setting new benchmarks for excellence.