Viritech and Haydale pursue new functionalized materials for Type V composite vessels for hydrogen storage

Goal is considerable weight savings via lightweight, impermeable pressure vessels without a liner, further advance in Graph-Pro structural storage tanks with integrated fixation.

Viritech (Nuneaton, Warwickshire, U.K.), developer of high-performance hydrogen powertrain solutions for the automotive industry, has announced that it is extending its cooperation with Haydale (Ammanford, Carmarthenshire, U.K.) a supplier of functionalized graphene-enhanced nanomaterials.

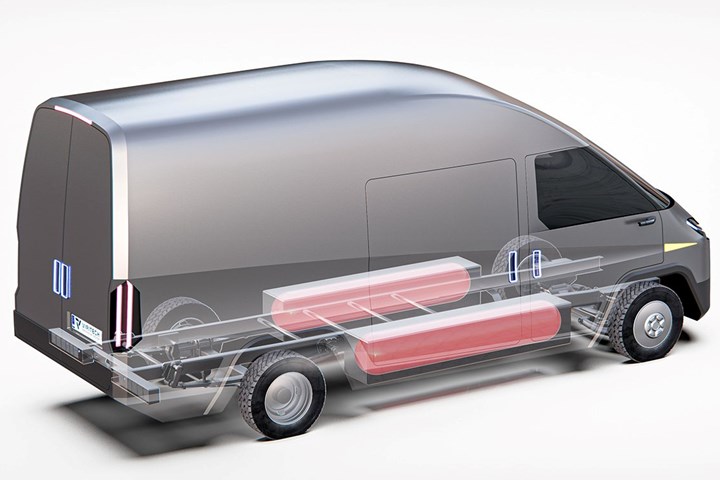

The two companies will work together on solutions for Type V, linerless composite pressure vessels for hydrogen storage in automotive applications, initially focusing on commercial vehicles. According to a recent report by the UK’s Advanced Propulsion Centre (APC), fuel cell electic vans will offer a lower total cost of ownership (TCO) than battery-electric vans by 2030, for applications where the vehicle travels more than 300 miles per day - vans on more than one shift a day would be a prime example.

By focusing on Type V linerless composite pressure vessels, Viritech and Haydale seek to develop the world’s most efficient vehicle storage system for compressed gaseous hydrogen. This technology is already being developed for automotive, aerospace, and marine applications, and has great potential in the emerging market for fuel cell vans. The new functionalized materials and resins being developed by Viritech and Haydale for Type V pressure vessels will deliver considerable weight savings and remove the need for an inner liner, which is currently required to provide a hydrogen-impermeable barrier in composite pressure vessels. Viritech and Haydale’s advanced graphene-enhanced carbon fiber composite material will enable the construction of impermeable pressure vessels without a liner.

In addition, Viritech will be further developing its Graph-Pro structural pressure vessels, which include fixing points that attach directly to a vehicle chassis — meaning no separate attachments or frames are required. This greatly simplifies the installation of pressure vessels and saves weight.

Having previously co-developed hydrogen storage solutions for Viritech’s iconic Apricale Hypercar, this collaboration marks the next stage in the Viritech-Haydale partnership and will play a significant role in bringing UK-developed and industry-leading storage solutions to the automotive market.

“We are delighted to be extending our partnership with Haydale,” says Timothy Lyons, CEO of Viritech. “With hydrogen’s growing emergence as a key pillar in the road to sustainable transportation, vehicle manufacturers are starting to design their first series-production fuel cell vehicles, and working together, our two companies are ideally placed to capitalize on one of the most important growth markets of the next two decades.”

“We are pleased to be continuing our work with Viritech,” says Keith Broadbent, CEO of Haydale, “and to be leading the way with ground-breaking hydrogen pressure vessel designs. Our expertise in functionalized nanomaterials alongside Viritech’s pioneering approach to fuel cell vehicles is an exciting step forward in providing the technology for this growing market.”

Related Content

-

Composite pressure vessels enable future energy storage

Q&A between Hexagon Purus, Infinite Composites and Hyosung USA delves into the future of H2 storage, including scalability and production goals, materials and application trends and other dynamics.

-

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

-

Forvia moves toward more sustainable automotive composites manufacturing

Automotive technology supplier Forvia shares sustainability goals and recent developments aimed at bio-based and recycled materials and ramping up hydrogen tank production for clean mobility.