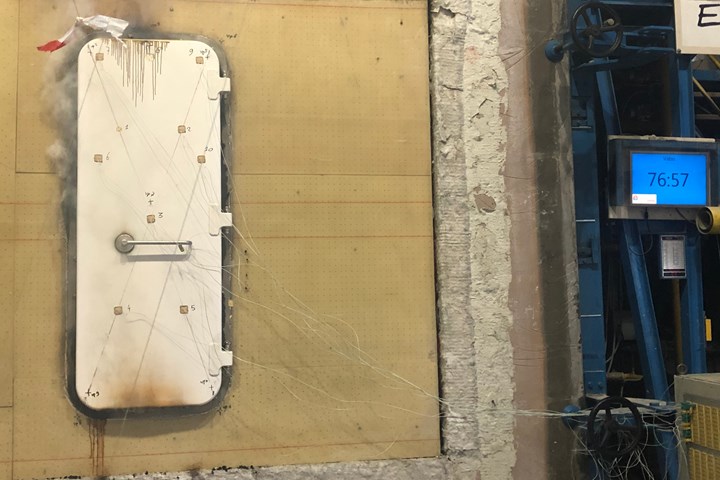

VABO Composites' maritime fire doors pass 60-minute resistance test

FRD60 composite doors cover all B15 and B30 requirements and enhance VABO portfolio for the company’s commercial, superyacht and naval sector client base.

Photo Credit: VABO Composites

VABO Composites (Emmeloord, Netherlands) has launched a new maritime fire door that meets all the criteria for the 60-minute resistance test. According to the company, these FRD60 doors enhance its portfolio for the company’s commercial, superyacht and naval sector client base around the world.

VABO manufactures composite doors and hatches for shipyards that wish to leverage the lightweight properties of composites in comparison to steel and aluminum. The company claims its composite products require virtually no maintenance, and VABO FRD30 doors cover all B15 and B30 requirements in terms of fire resistance.

“VABO has made significant investments in developing a door that reaches the 60-minute target,” explains sales and marketing manager Jeroen van Deutekom. “Although it took considerable time and effort with a stringent testing regime, the VABO team has now amply passed the 60-minute milestone. Our tests follow the FTP code [FRD60] to cover the equivalent A60 and A0, with VABO’s high quality level guaranteed.”

According to VABO, this expansion means it can now support an even wider part of the markets in which it operates, with a complete selection of hinged doors and hatches that includes those which need to be fire resistant.

Related Content

-

Orbital Composites wins AFWERX award for Starfighter drone fleet

Under the TACFI contract, Orbital is implementing the AMCM process to build 3D printed composite multi-mission UAS aircraft, surpassing $10 million in government awards.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.