SPE ACCE 2018 keynote to highlight carbon fiber pickup box

Mark Voss, engineering group manager at General Motors Co. will discuss the creation of the new “CarbonPro Box” on the 2019 MY GMC Sierra Denali.

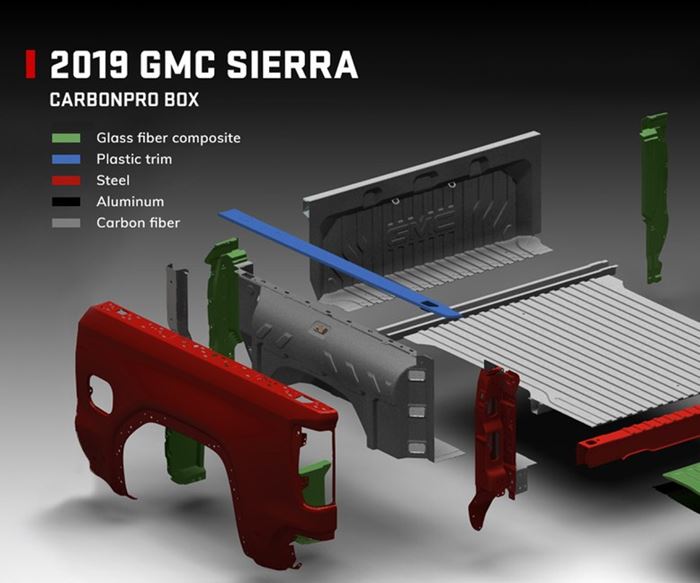

The SPE Automotive Composites Conference (ACCE, Troy, MI, US) team announced April 11 the keynote “The World’s First Carbon Fiber Pickup Box” to be presented at their 18th annual event Sept. 5 - 7 at the Suburban Collection Showplace in Novi, Mich. Mark Voss, engineering group manager, Body Structures Advanced Composites and Pickup Boxes at General Motors Co. will highlight the material change enabling the development of a 62 lb (28 kg) weight savings, 40% mass reduction and improved performance with their new CarbonPro Box on the 2019 MY GMC Sierra Denali.

“Composites – Driving Innovation,” is the theme for this year’s event reflecting the growing interest automotive OEMs have in the latest composites technologies. In addition to keynote presentations, The ACCE features approximately 80 technical presentations, three roundtable discussions, and over 100 sponsors with close to 80 exhibits highlighting advances in materials, processes and equipment for both thermoset and thermoplastic composites in a wide variety of transportation applications. Networking breakfasts, lunches and receptions enhance the value of the event that attracts over 900 attendees worldwide. The Automotive and Composites Division of the Society of Plastics Engineers (SPE, Troy, MI, US) jointly produce the ACCE to educate the automotive industry about the benefits of composites in automotive applications.

For more information see www.speautomotive.com.

Related Content

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.