Low & Bonar licenses EconCore’s thermoplastic honeycomb technology

Using EconCore’s honeycomb technology, Low & Bonar has developed a lightweight flooring underlay product designed with high acoustic properties.

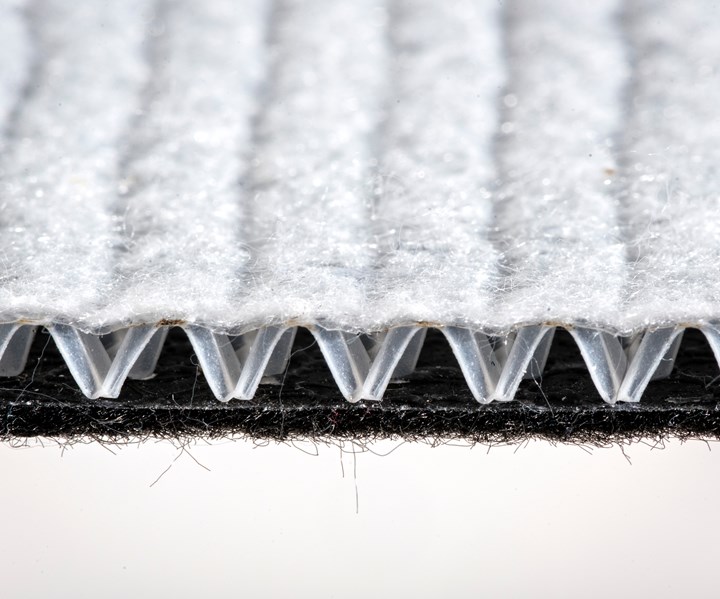

A close-up view of Colcore Sonic, showing the relaxed honeycomb core with non-woven performance fabrics. Source | Low & Bonar and EconCore

Advanced fabrics company Low & Bonar (London, U.K.) has signed a license agreement for the use of EconCore’s (Leuven, Belgium) thermoplastic honeycomb technology. At the Domotex trade show in Hannover, Germany (Jan. 10-13, 2020), Low & Bonar launched a new flooring flooring product using EconCore’s honeycomb technology.

The product, called Colcore Sonic, uses EconCore’s continuous, high-volume production process for lightweight thermoplastic honeycomb sandwich panels. Colcore Sonic is deliverable on a roll, rather than as a rigid panel, for easy handling, storage and installation, and it is said to be lightweight and thin while exhibiting strong soundproofing and high compression strength properties.

The new product concept was developed in 2018, followed by a series of testing, learning and further optimization. Relevant industry qualification tests were achieved to demonstrate the product meets and exceeds industry standards, Low & Bonar says.

Independent testing found that Colcore reduced impact sound by 20 decibels and airborne sound transmission is 57 decibels, both defined as the noise perceived in a room below. Radiated walking sound, defined as walking noise in the same room, registered at 56.4 Sone (a unit of loudness), considered to be a comfortable sound level. The results demonstrate that the product is ideal for flooring of both, commercial and residential buildings.

“Even with the latest generation of leveling compounds, preparing subfloors prior to the installation of vinyl click flooring is time-consuming. Unrolling, cutting and positioning this high-performance underlay system is all it takes to smooth out uneven surfaces in minutes rather than hours or days,” says Soon Joo Bovenschen, new technology manager at Low & Bonar.

“This license agreement and the subsequent successful product development is a result of intensive work and an excellent partnership between EconCore and Low & Bonar,” says Tomasz Czarnecki, chief operating officer at EconCore.

Related Content

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

MFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;width=70;height=70;mode=crop)