48th auto-plastics competition highlights changing industry

Additive manufacturing, autonomous vehicles, greener parts featured prominently.

On November 7, a global audience of nearly 1,000 gathered for the Society of Plastics Engineers’ (SPE, Bethel, CT, US) 48th-annual Automotive Innovation Awards gala to learn this year’s category and Grand Award winners.

When it started in 1970, the competition — organized by the Automotive Division of SPE — was intended to draw automaker attention to plastics as an underutilized material in the automotive industry. At the time, most polymeric content on cars was restricted to ashtrays, buttons, knobs, rubber mats, seals and tires. To borrow a tagline from that era, “We’ve come a long way, baby.”

Today, the American Chemistry Council (Washington, DC, US) reports that polymeric materials make up 50% of the volume of new passenger vehicles but only 10% of their weight. And you’d better believe that content is increasing as we draw closer to 2025 fuel efficiency mandates in North America and tailpipe emissions mandates in much of Europe and Asia.

The trends changing how automotive plastics and composites are used have been spelled out pretty accurately in SPE’s annual parts competition over the last half-century and this year’s contest was no exception, which is why it’s so interesting to participate as a judge. For example, one of the long-standing competition rules is that nominations must be used on vehicles commercially available for purchase (or in use to produce commercial parts) by November 1st of the year the nomination is submitted — although they also can be submitted after start of production (SOP). Given the rapid growth in additive manufacturing and 3D printing technologies, and the increasing breadth of materials available, it was not surprising to see that organizers added a new category for this year’s competition for Additive Manufacturing. Eight strong nominations were entered, including lighter, more ergonomic lift assists, assembly alignment fixtures, and B-side body tools for final assembly that replaced much heavier (and often more metal-centric) traditional tools that were costlier and took far longer to produce. Carbon fiber-reinforced polyamide 12 (CF-PA12) featured prominently in several cases. Other applications included additively manufactured inserts for injection molding tools that replaced the porous, sintered metal-matrix composite, Porcerax (International Mold Steel Inc., Florence, KY, US), which reportedly is more sensitive to mold release and mold-cleaning products and doesn’t last as long. Still another application was an OEM replacement part for an older model vehicle whose original tooling had been misplaced. For the small number of parts needed each year, 3D printing was far more cost-effective than producing new injection molding tools. In fact, that application was reportedly the auto industry’s first commercial use of CLIP technology from Carbon Inc. (Redwood City, CA, US) to produce thermoset parts — in this case in epoxy.

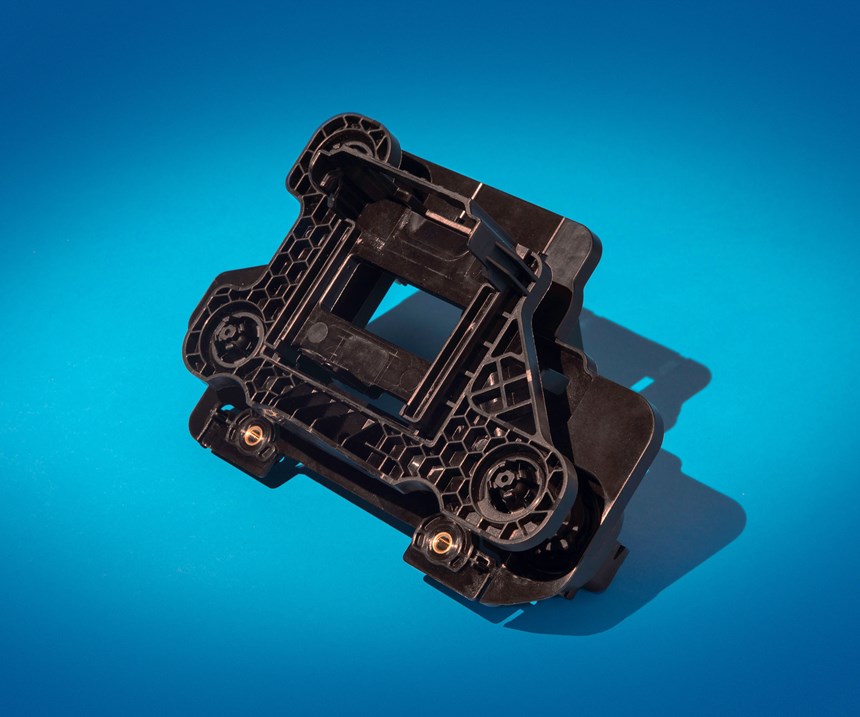

Another sign of the times is that a front-mounted composite millimeter-wave radar bracket with breakaway functionality for pedestrian impact protection in 33% glass-reinforced PA 6/6 (GR-PA66) was a Safety category finalist. In recent years there have been more and more nominations with clever ways to incorporate forward- and rear-projecting cameras and various sensors in bumper fascia, rear fins, front grilles, and even in a rear taillight assembly. As autonomous vehicles move out of testing and begin entering roadways in quantities, expect to see more nominations like these.

The Environmental category also had a strong showing this year. Judges had to choose among applications that used up 11.9-million ft2/1.1-million m2 of old carpet backing plus 26,250 lb/11,907 kg of recycled tire rubber versus several 100% post-industrial recyclate (PIR) applications — one of which, remarkably, was a Class A exterior part — and a third that combined PIR automotive scrap plus post-consumer recyclate (PCR) from food packaging, as well as the industry’s first use of a combination of cellulose fiber (from sustainable forestry) plus long-glass fiber polypropylene (LGF-PP). In every case, weight and costs were saved, greenhouse-gas emissions reduced, and presumably more positive lifecycle analyses yielded.

Related Content

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreAerospace prepregs with braided reinforcement demonstrate improved production rates, cost

A recent time study compares the layup of a wing spar using prepreg with A&P’s TX-45 continuous braided reinforcement versus traditional twill woven prepreg.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More

.jpg;width=70;height=70;mode=crop)