RocTool composite demo at K 2016

In partnership with Flextronics and Arburg, the RocTool new technology combines the forming of a composite sheet and injection overmolding of thermoplastic in the same process.

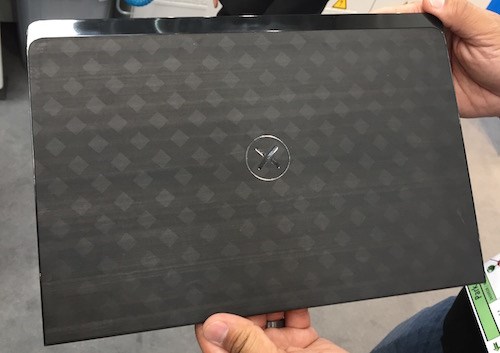

RocTool is showcasing its latest molding technologies at K 2016. The company has several demos throughout the show including one of its Induction Dual Heating (IDH) process, a combination of plastic and composite materials with the new RocTool heating configuration. In partnership with Flex and Arburg, the RocTool new technology combines the forming of a composite sheet and injection overmolding of thermoplastic in the same process. RocTool presented the process for a "hybrid" 14-inch computer cover that is 1.0 mm thick, bringing the benefits of composite (high modulus, lightweight) and plastic (cosmetic integration functions integrations) in one and the same product while eliminating secondary operations. This is done in a 1-minute cycle time per part and in the same machine. Pretty cool technology. Here's the computer cover:

Check out video of the process below:

Related Content

-

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?