Covestro to provide materials to “Sonnenwagen Aachen” team for solar race

The material manufacturer supports the development of a solar-powered electric car with material donations, technical service and as a gold sponsor.

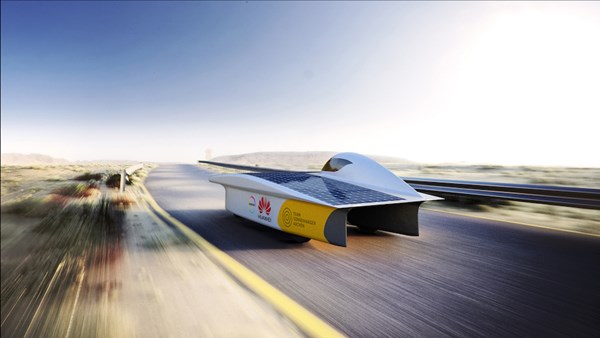

Covestro will take advantage of the Sonnenwagen project to test various materials under the harsh climate conditions prevailing along the race’s route. (Photo credit: Sonnenwagen Aachen).

A group of students at RWTH Aachen University and Aachen University of Applied Sciences are working on developing a solar-powered electric car for the World Solar Challenge 2017 from October 8 to 15 in Australia. The approximately 45 junior researchers established the “Sonnenwagen Aachen e.V.” association, with the support of their professors.

Covestro (Leverkusen, Germany) has cultivated a long-term partnership with the university and is supporting the “Sonnenwagen” (German for “solar car”) project as both a material and technical service provider and Gold Sponsor. The two partners recently signed a cooperation agreement for the project. The Leverkusen-based company is very much familiar with using its materials for solar mobility: As an official partner of the Solar Impulse project, it made a significant contribution to the success of the first manned flight around the globe in an aircraft powered exclusively by solar energy.

Covestro wants to take advantage of the Sonnenwagen project to test various materials under the harsh climate conditions prevailing along the race’s route: temperatures of up to 45 degrees Celsius, high UV radiation and a high air dust content are typical there in October. The most important product application is a three-layer polyurethane coating from PPG (Pittsburgh, Pa.) The coating is particularly suited to application on body parts made of carbon fiber composites.

The climate conditions have a significant impact on the top clearcoat. It is formulated with the bio-based hardener Desmodur eco N 7300 from Covestro, 70 percent of whose carbon content is sourced from biomass.

The Sonnenwagen further incorporates polyurethane and polycarbonate materials from Covestro, which contribute to the lightweight and aerodynamic design of the solar car.

“As sustainability is part of our strategy, we support this ambitious project, in which young researchers want to show that innovative and sustainable mobility concepts are already possible today,” says Markus Steilemann, board member for innovation and chief commercial officer of Covestro. “Solar mobility can make a key contribution to protecting the climate and conserving fossil resources. With our developments and this project partnership, we want to demonstrate our commitment to innovation and sustainability, but also to supporting junior talents.”

The World Solar Challenge is considered to be the toughest solar race on earth and celebrates its 30th anniversary this year. Teams from all over the world compete every two years in their homemade vehicles to win the 3,000 kilometer race from Darwin to Adelaide – without using any fuel.

Related Content

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.