Source | Scheurer Swiss GmbH

A team of engineering students at ETH Zurich (Zurich, Switzerland) is working to develop an autonomous agricultural robot to serve as a sustainable alternative for the use of herbicides in agriculture. The project began in September 2019, and in June 2020, the first functional prototype, called Rowesys (short for Robotic Weeding System), went into a practical testing phase.

The project, run by 10 ETH Zurich students with the assistance of eight coaches and sponsors, aims to demonstrate how digitalization and smart technology can help minimize negative environmental effects of herbicides within the agriculture industry. Among the project’s sponsors is engineering company Scheurer Swiss GmbH (Volketswil, Switzerland), which is providing the team with 3D-printed, carbon fiber-reinforced components for the robot as well as its engineering expertise in an advisory capacity.

Curved, 3D-printed composite slats on the front and back of the robot enable LED light displays to be seen through the chassis. Source | Scheurer Swiss GmbH

The underlying concept for the Rowesys robot is based on mechanical, rather than chemical, weed killing. The agricultural robot pulls small plows through the soil that pull weeds out of the ground by the roots, leaving them to dry up on the surface. The robot drives autonomously through the rows of plants, detecting the end of the field and moving between the roads with the help of built-in cameras.

The Rowesys prototype is said to meet many of the project’s goals for an autonomous agricultural robot in terms of efficiency, reliability, autonomy, safety and user-friendliness. According to Scheurer Swiss GmbH, the use of 3D-printed, carbon fiber-reinforced materials for many of the robot’s components helps contribute both to the cost efficiency of the project and the robot’s design flexibility.

The robot’s composite top cover. Source | Scheurer Swiss GmbH

“Only with the technology of carbon-reinforced 3D printing is it even possible to produce such a precisely fitting, filigree and yet stable component,” says Dominik Scheurer, CEO of Scheurer Swiss GmbH.

Given the design parameters and delicate nature of the components, chopped carbon fiber-filled polyamide 12 (PA12) was chosen, and the parts were manufactured via a select laser sintering (SLS) additive process.

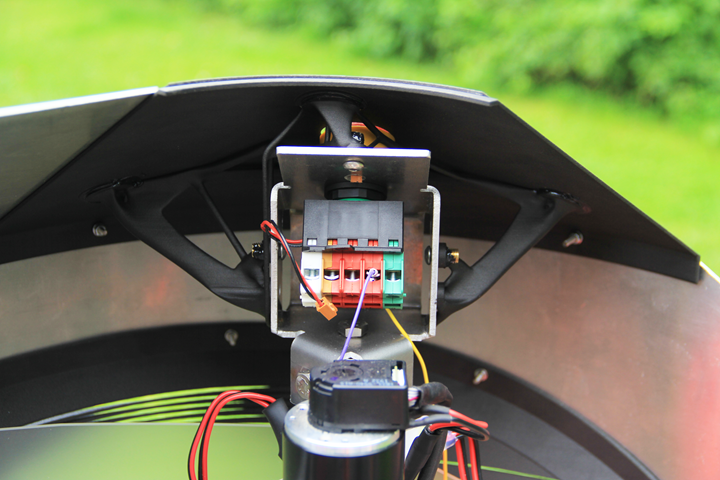

The robot has an aluminum chassis, with composites featured in the most detailed components such as parts of the robot’s top cover, wafer-thin slats on the front and back of the robot, a filigree component that connects the electronics to the chassis, and fixation brackets on the bottom of the robot. Slats in the chassis are backed by LED lights that signal the robot’s status during operation. The electronics connector’s unique shape is designed for minimum material usage to reduce weight on the robot, with composites contributing to the stability requirements needed to hold the electronics in place while the robot is moving.

The electronics connector within the chassis of the robot is designed for minimal material usage while maintaining a high degree of stability. Source | Scheurer Swiss GmbH

Currently, the project has resulted in a functional prototype designed specifically for sugar beet fields — chosen for the relatively high use of herbicides by sugar beet farmers. Test results so far have indicated that using a mechanical weeding robot like Rowesys can significantly reduce pollution of groundwater, air and the crops themselves.

“What motivated me about this project, apart from the relevance of what I learned and the chance to gain practical experience in teamwork, was the sustainability of herbicide-free sugar beet cultivation. Because up to now, there has been no investment in more sustainable production in this area of agriculture,” says Nico Burger, ETH student on the software and controls team at Rowesys.

“The focus project Rowesys is an example of how digitization and the use of innovative materials can produce efficient and intelligent technical achievements,” Scheurer says.

Related Content

Composites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.

Read MoreEuropean boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

Read MoreJEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More

.jpg;width=70;height=70;mode=crop)