Next-generation automation for high-performance composites fabrication

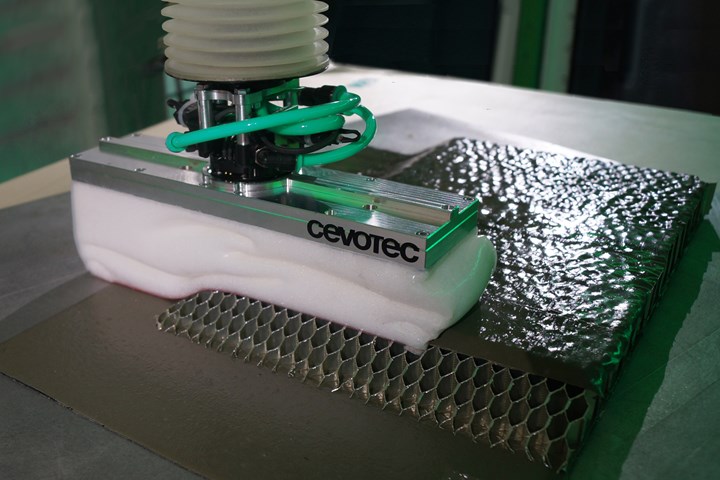

Cevotec’s Fiber Patch Placement technology uses robot-based systems to automate material layup for complex composite parts and structures, saving 20-60% in production time and costs.

Automation specialist Cevotec (Unterhaching, Germany) has developed the Fiber Patch Placement (FPP) process to enable the precise, repeatable and consistent application of fiber plies - in various sizes and of different material types onto complex geometries that are difficult to fabricate using traditional composites manufacturing methods. The result, says Cevotec, is savings of 20-60% in production time and costs, and a highly optimized and efficient composites production process. In this Digital Demo, one of Cevotec’s co-founders introduces the FPP process, explores more recent technology developments, reviews the digital process chain of FPP from CAD to finished part, summarizes equipment options, provides examples of parts and structures made with FPP, and offers suggestions on how to get started with FPP.

Related Content

-

Ultra high-rate composite deposition system trials to surpass layup targets

The NCC, alongside partners Loop Technology, Coriolis and Güdel, are on track to deliver dry fiber deposition rates exceeding 350 kilograms/hour, seven times more than standard aerospace rates.

-

Broetje-Automation works with Boeing Germany, consortium in “Shimless Assembly” project

Foundation for future aircraft programs aims for -75% manufacturing time, -25% cost via end-to-end digitization, tolerance compensation and force-controlled joining.

-

Clemson Composites Center leads research in low-cost composite tooling

Innovative technology approach to use additive manufacturing and artificial intelligence to produce tools faster, at a lower cost and with less environmental impact.