Work In Progress

Reinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

WatchFilament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

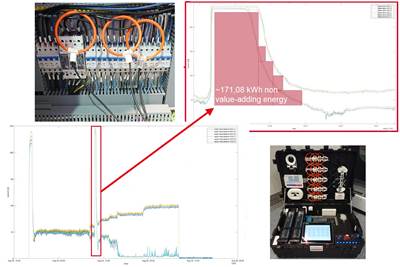

Read MoreMeasuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

Read MoreDemonstrator project targets circularity solutions in carbon fiber composite sports equipment

The Carbon Fibre Circular Alliance (CFCA) brought together OEMs and technical partners to reclaim short carbon fibers from end-of-life sports equipment, realign into continuous prepreg tapes and remanufacture into new equipment.

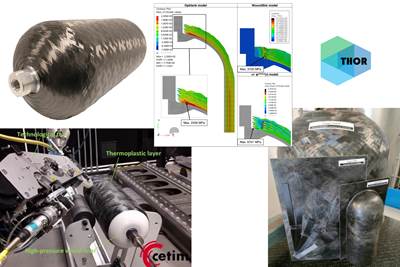

WatchUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreInnovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

Read MoreManufacturing tech for scalable Type V hydrogen tank fabrication, CFRP lifecycle management

Cygnet Texkimp’s Multi Roll Stack and composite recycling technology catalyze ASCEND program’s mission to optimize aerospace, automotive hydrogen storage and CFRP sustainability.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

WatchThermoplastic composite, tube-shaped preforms for large-volume manufacturing

Starting with the sporting goods and bicycle market, French startup 3DiTex targets its continuous preforming system for thermoformable, thermoplastic composite tubes in complex geometries.

Watch