Matlantis report indicates AI turning point for materials science

Industry report, based on a survey of 300 U.S. researchers, finds materials and engineering R&D at an AI inflection point, signaling an urgent need for faster, trusted tools.

Matlantis Inc. (Cambridge, Mass., U.S.), the U.S. hub of the materials discovery arm of Japan’s AI company Preferred Networks Inc. (PFN, Tokyo), has announced the release of a research report titled “The State of AI‑Accelerated Materials R&D” that is based on a survey of 300 materials science and engineering professionals across the U.S. The report reveals an inflection point: Materials R&D has entered its mainstream AI era, with nearly half (46%) of all simulation workloads now running on AI or machine learning methods.

Yet this acceleration comes with significant growing pains. An overwhelming 94% of R&D teams reported abandoning at least one project in the past year because the simulations ran out of time or computing resources, leaving potential discoveries unrealized. The findings underscore the industry’s urgent need for faster simulation capabilities to keep pace with surging innovation demands.

At the same time, the economic stakes for accelerating R&D have never been clearer. According to the survey, organizations are saving roughly $100,000 per project on average by leveraging computational simulation in place of purely physical experiments. This proven ROI is driving heavy investment in new tools and workflows. Researchers are also eager to speed up their work even if it means accepting minor trade-offs in precision — 73% of respondents said they would trade a small amount of accuracy for a 100-times increase in simulation speed.

“This is the quiet crisis of modern R&D: the experiments that never happen,” says Daisuke Okanohara, CEO of Matlantis. “Our study shows nearly every materials research team has had to leave promising projects on the shelf, not for lack of ideas, but because their tools couldn’t keep up. It’s a stark wake-up call that traditional trial-and-error methods are too slow and costly for today’s pace of innovation. We’re at a turning point where the industry must embrace faster, smarter approaches to ensure crucial discoveries don’t get left behind.”

The report also highlights that trust and security remain paramount. Every team surveyed expressed concerns about protecting intellectual property when using external or cloud-based tools, and only 14% felt “very confident” in the accuracy of AI-driven simulations. In sum, materials scientists are hungry for speed and efficiency, but solutions must also earn their confidence.

For Matlantis, the survey’s findings validate the urgency of its mission. The company’s cloud-native Matlantis platform was built to accelerate materials discovery through AI-accelerated, high-speed simulations without compromising on scientific fidelity or data security. By integrating advanced neural-network potentials with proven physics, Matlantis enables researchers to iterate rapidly while maintaining confidence in the results.

“At Matlantis, we anticipated this inflection point and designed our platform to deliver acceleration and efficiency without sacrificing accuracy or security,” Okanohara says. “Our AI technology lets scientists run high-fidelity simulations in hours instead of months, with the assurance that those results can be trusted. As R&D teams race to develop sustainable batteries, catalysts, semiconductors and more, Matlantis is here to ensure they can carry those projects through to breakthrough results rather than abandoning them mid-stream.”

The full findings and analysis are detailed in the report, which is available for download on Matlantis’ website.

Related Content

Aurora reveals latest SPRINT X-Plane design concept

An Aurora and Boeing team advances its high-speed, vertical lift concept to the preliminary design phase, which features three lift fans, a more refined composite exterior and an uncrewed cockpit.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

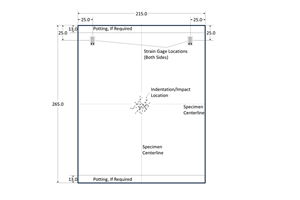

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreProving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Read MoreRead Next

Siemens adds AI to Simcenter Testlab, reinventing modal testing and analysis

Simcenter Testlab, already used with composites, now uses intelligent test automation and AI assistance to execute physical testing workflows faster, smarter and earlier in structural design programs.

Read MoreModular, hybrid machining centers with intelligence for complex composites

Machine Tool Camp’s purpose-built systems combine CNC machine centers and robots with specialized machining tools, clamping and configuration, automating steps before and after, including data integration, to empower manufacturers for the future.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More