NCC successfully demonstrates AFP manufacture of CMC parts

Core Research program adapts existing AFP technology and identifies optimal deposition parameters using a novel 3M towpreg material for wider CMC use.

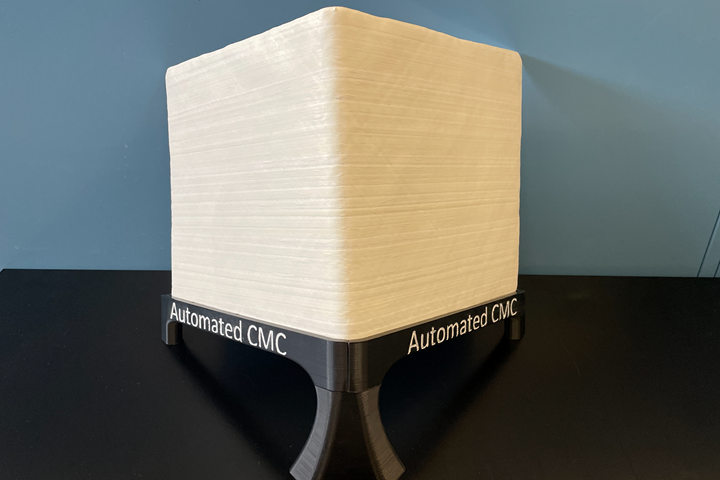

Engineers at the National Composites Centre (NCC, Bristol, U.K.) have completed what they say is a European first by manufacturing ceramic matrix composites (CMC) using automated fiber placement (AFP) technology, paving the way for the materials’ high-temperature capabilities to be unlocked within engines.

The project — completed as part of the NCC’s Core Research program, and supported by Rolls-Royce, Reaction Engines, MBDA and 3M — has demonstrated that a novel oxide-based ceramic towpreg material from 3M can be used in automated deposition.

While conventional nickel-based superalloys have a maximum continuous temperature of approximately 800°C, oxide-based CMC can operate at 1,000°C, with the higher operating temperature potentially improving the efficiency of aerospace engines and reducing fuel consumption and subsequent CO2 emissions.

“In the next year we hope to use our optimized manufacturing parameters to create even more complex geometries, starting with curved surfaces, to closer represent industrial parts.”

However, the widespread use of CMC is currently limited to high-value applications, such as heat shields and turbine vanes. Being able to process a more affordable version of the material using AFP technology will reduce the final cost of making CMC parts, the NCC team believes, making them a more appealing proposition for industries that require components that can withstand high temperatures. Furthermore, using an automated process has the potential to offer optimized control over material deposition and could prove a vital innovation to improve material consistency.

The project team adapted existing AFP technology, typically used to process organic matrix composites like carbon fiber-reinforced epoxy materials, to process 3M’s material. They also investigated how process parameters such as speed, heat and compaction force influence the material deposition and quality. According to the NCC, identifying the optimal deposition parameters reduces the material variability, removing one of the largest challenges for CMC to be used more widely. This could also lower the cost of CMC and create less waste.

“By manufacturing 3D trial parts, we have demonstrated compatibility of CMC towpregs with existing AFP equipment,” Dr. Dave King, engineering capability lead for advanced materials at the NCC, says. “In the next year we hope to use our optimized manufacturing parameters to create even more complex geometries, starting with curved surfaces, to closer represent industrial parts. With 3M’s support, we are also investigating wider material formats to reduce the number of inter tape joints in the material to increase its performance. These factors are critical for their deployment in industry.”

Angus Braithwaite, senior materials engineer at Reaction Engines, notes that, alongside the development of its air-breathing, high-speed propulsion systems, Reaction Engines recognizes that CMC will play an important part in optimizing space-access, high-speed flight and other cutting-edge aerospace applications. “Solving the high-cost/low-volume manufacture constraints currently associated with CMC and their supply chain would greatly contribute to advancing progress in these sectors,” Braithwaite adds.

Related Content

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.