Additive manufacturing reimagined: large-scale, fiber-reinforced thermoset printing

ORNL, MVP and Polynt-Reichhold launch world’s first commercially available, large-scale thermoset composite additive manufacturing machine and reactive print material.

Magnum Venus Products (MVP), a leading manufacturer of composites application equipment, began working on its Reactive Additive Manufacturing (RAM) machine in 2017. That same year, Polynt, a supplier of thermoset polymers, gelcoats and SMC, began work with Oak Ridge National Laboratory (ORNL) to develop a reactive material to use in the RAM system. By CAMX 2018 (Oct 15-18, Dallas, TX), the team’s efforts were recognized with the ACE Infinite Possibility Award for its Large Area 3D Printer for Thermoset Materials. This week, CW attended a launch event where these three partners demonstrated the world’s first large-scale thermoset composite additive manufacturing system at the Dept. of Energy’s (DOE) Manufacturing Demonstration Facility (MDF) at ORNL.

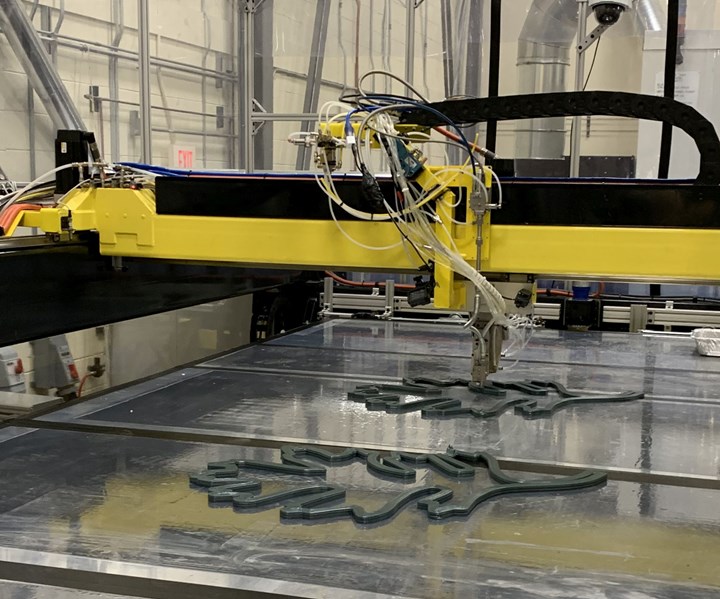

MVP’s Reactive Additive Manufacturing (RAM) machine and Polynt Reactive Deposition PRD-1520 print material are demonstrated at Oak Ridge National Laboratory (ORNL). SOURCE | CW

Reactive Additive Manufacturing (RAM)

Although technology has been developed enabling 3D printing with UV-cure thermosets, RAM and Polynt Reactive Deposition PRD-1520 print media comprise the first large-scale system — current build envelope is 8 feet by 16 feet by 3.5 feet — to use a reactive resin that cures at ambient temperature without UV activation. This technology is aimed at low-cost fixtures, thermoforming tools and autoclave molds, as well as a wider range of applications. “RAM delivers stronger, more energy-efficient products with improved thermal properties,” explained MVP CEP Bob Vanderhoff.

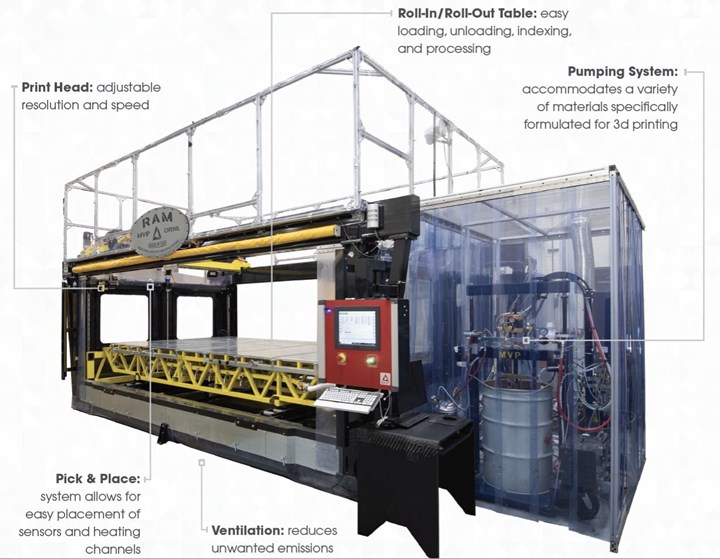

The RAM system includes the large print platform and a floor-mounted MVP pumping system, with only the printhead mounted onto the computer-controlled gantry. The pumping system accurately measures and meters the short glass fiber-reinforced vinyl ester resin and peroxide initiator into a static mixer in the printhead. The mixed resin is then extruded through a nozzle, similar to most fused deposition modeling (FDM) systems. “Using a 1.2-millimeter diameter nozzle, print speed is roughly 1.2 meters/second,” said John Lindahl, ORNL technical lead for thermoset polymers/composites in additive manufacturing (A.M.). “RAM can achieve FDM-scale features while still delivering a high output of almost 7 kg/hr (15 lb/hr).”

SOURCE | https://www.mvpind.com/3d-printer/

The build platform is modular, made from eight segments. “Each of these is easily removed and indexed,” notes Vlastimil Kunc, ORNL manufacturing science group leader. “I can move these with just my fingers, so you could pull one out and replace it with another if you wanted to post-cure or machine it.” This then modularizes the process so that it can be scaled for high-volume parts production. “We have also integrated pick-and-place robot capability into RAM to embed sensors, thermocouples, RFID tags and heating elements, for example, as needed,” he adds.

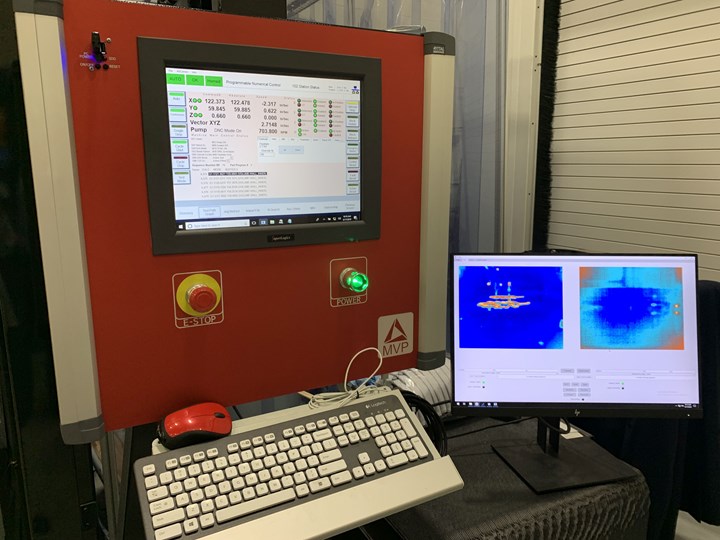

“RAM is also outfitted with infrared cameras and optical sensors to monitor exotherm and temperature during the build,” notes Lindahl. “We have developed a 1D thermo-chemo-rheological model that we use with a semi-infinite wall, which is the toughest feature to build with these materials. The model tells us, based on print resin and reaction, what layer time you need, how fast you can print (volumetric output) and how hot it will exotherm. All of this guides us in optimizing RAM print parameters and fully understanding the viscoelastic behavior of the printed resin during gel, cure and fully completed print.”

The RAM printer is equipped with infrared cameras and optical sensors that monitor exotherm and conformance to optimized parameters, as defined by ORNL’s thermo-chemo-rheological model. SOURCE | CW

Polynt Reactive Deposition (PRD-1520) for efficiency

PRD-1520 is a pre-promoted, pre-compounded unsaturated vinyl ester resin designed with a high viscosity (2.5-3.0 millions cPs) for pumping and 3D printing. It was designed for use in the MVP RAM printer, featuring low shrinkage and a heat deflection temperature (HDT) of 94°C/201°F and a glass transition temperature of 107°C/225°F. This is compared to an HDT of 56°C, 88-98°C and 110°C for PLA, ABS and nylon, respectively, according to 3D printing filament suppliers. “However, PRD-1520’s patent-pending chemistry enables chemical bonding between the printed layers, which increases the properties of 3D printed structures, including 2 to 4 times greater z-direction strength compared to thermoplastics,” explained Polynt R&D director Steve Voeks. He also noted the resin’s long open time (gel time of 20-25 minutes), “which makes it possible to print large structures with starts and stops and long intervals in between layers.” This ability to print onto previously deposited yet still soft materials significantly increases tool path freedom.

“The tool path development that we’ve done is unique to thermoset materials,” explained Lindahl. “We can print very efficient structures by starting with a sparse infill and then topping that with a zero-void layer. We begin with alternating 0°/90° layers and then to 0° and 90° print paths in a single, transition layer which is then topped with a solid print layer. This allows you to print large surfaces while significantly reducing print material as well as weight, print time and cost.” A technical paper explaining this technology will be presented by ORNL post-doctoral researcher Chris Hershey at CAMX 2019 on Thursday, Sep 26 at 10:00 am. “Large-Scale Reactive Extrusion Deposition of Sparse Infill Structures with Solid Perimeters” has already been awarded CAMX 2019 Outstanding Technical Paper and best paper in the Additive Manufacturing conference track.

“Using PRD-1520, RAM is currently the most energy-efficient 3D printer for polymer and composite materials,” says Lindahl. Notably, the thermoset material does not require a heated table or chamber. Also not needed is the heat normally required to melt thermoplastic pellets.

“We have enjoyed a mutually beneficial collaboration with Polynt and MVP looking at next-generation reactive polymer additive manufacturing,” said Bill Peter, MDF Director. “With the support of DOE’s Advanced Manufacturing Office, we plan to continue fundamental research to improve this technology and better understand the underlying science while demonstrating further energy-efficient processes and applications with our industry partners.”

To learn more, visit MVP in booth G2 and ORNL in booth S25 at CAMX 2019 (Sep 23-26, Anaheim, CA) or contact Hannah Jay at MVP, Rick Pauer at Polynt or Jennifer Burke at ORNL.

Related Content

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)