CW Blog

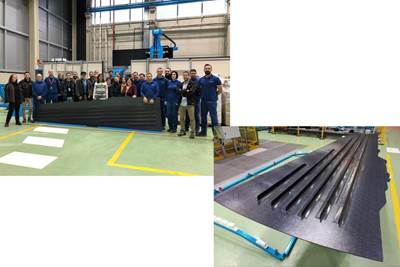

CIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

WatchFairmat and the rise of deep tech in France

This first column in CW’s new Investors and Startups column series takes a closer look into the region of France, decoding the technologies, teams and funding actors driving its composites innovation.

Read MoreAdvancing thermoplastic composite primary structure and morphing wings

The HERWINGT project in Clean Aviation seeks to ready technologies — including at least 16 composite demonstrators — for a hybrid-electric regional aircraft with 50% less fuel burn to be launched by 2035.

WatchThere's a lot up in the air

Trade tensions and supply chain shifts — what the U.S.-China dispute means for aerospace and composites suppliers.

Read MoreOligomer polymer engineering transforms 100% recyclable thermoplastic composite paradigms

MET-OL thermoplastic technology alters high molecular weight polybutylene terephthalate into low-viscosity oligomers, enhancing fiber impregnation and catalytic repolymerization for fully recyclable, high-performance composites.

Read MoreCompositesWorld introduces new column: Startups and Investors

Welcome to an exploration of how startup and investor ecosystems around the globe are shaping the future of composites.

Read MoreComposites Fabricating Index loses ground in April amid tariff uncertainty

Latest reading of 47.3 is fueled by a drop in new orders as markets react to quick changes in trade policy.

Read MoreSpanish startup to ramp up production of “recyclable” EV prototype

Liux’s BIG electric vehicle features multiple structural components manufactured via RTM from flax fabric and a thermoset resin said to enable the entire component to be recycled and reused again.

WatchNear-zero erosion ultra-high temperature CMC

K3RX commercializes UHTCMC for a wide range of markets, demonstrating performance in prototypes, assemblies and advancing manufacturing to reduce cost.

Read MoreLaser cleaning in composites manufacturing

Laser cleaning technologies for cleaning production molds for composites offer alternatives to harsher, less-friendly methods with features like automation and higher power cleaning.

Read MorePost Cure: Composite assemblies orchestrate smaller satellite designs, payload flexibility

CubeSats have become key to space exploration and R&T development, though they are often expensive to build and launch. Funded efforts like the DiskSat program aim at mitigating these challenges.

Read MoreComposites end markets: Aviation and advanced air mobility (2025)

Despite persistent supply chain issues, markets were set for healthy growth before Trump policies and tariffs, yet long-term trends favor composites in new platforms. Meanwhile, advanced air mobility shakes out and moves forward.

Watch