SPE ACCE report

Automotive composites still on the horizon — are they getting closer?

Nearly 850 attendees gathered to assess the state of composite materials in automotive platforms at the Society of Plastics Engineers’ Automotive Composites Conference and Exhibition (ACCE), held at the Diamond Banquet and Conference Center at the Suburban Collection Showplace venue in Novi, Mich., from Sept. 9-11. ACCE welcomed 68 exhibitors and, with the aid of numerous event sponsors, fielded a technical program that comprised more than 80 presentations, roundtable discussions and keynote speeches covering advances and issues in the areas of thermoset composites, thermoplastic composites, nanocomposites, virtual prototyping/testing, sustainability as well as business trends and technology solutions for automotive applications of composites.

In the past, the ACCE’s executive panel discussion has been a “reality check” for composites advocates. This year was no exception. Moderated by Jay Baron, president and CEO of the nonprofit Center for Automotive Research (CAR, Ann Arbor, Mich.), the panel included Dr. Paul Krajewski, global manager and technical Fellow for vehicle mass integration and strategy at General Motors (Detroit, Mich.), Tom Pilette VP, product and process development, at automotive systems supplier Magna Exteriors (Troy, Mich. and Aurora, Ontario, Canada), Harry Singh executive program manager at design firm EDAG (Fulda, Germany), Martin Starkey, director, Gurit UK (Newport, Isle of Wight, U.K.) and Dr. Peter Friedman, manager of manufacturing research, Ford Motor Co. (Dearborn, Mich.). Reluctant to embrace composite materials per se, panelists preferred to discuss lightweighting in terms of a multi-material solution.

General Motors’ Krajewski admitted that there are many opportunities for saving weight, including interiors, wheels and vehicle frames, but he observed that “the customers only want a solution that works, and they don’t care about which material is used.” He went on to say that whatever material is selected, his team needs to be able to model it and predict its performance, and he suggested composites suppliers take their cue from the steel industry, where competitors have worked together as a group to collectively develop new, lighter material forms.

Magna’s Pilette agreed, urging the audience to develop working partnerships, among OEMs, suppliers and material manufacturers, to help bring down composites cost.

EDAG’s Singh pointed out that the steel industry has reinvented itself, quoting a cost of only $500 for a complete steel car body. Today’s steel, he added significantly, is 10 times stronger and better in quality than that of a decade ago. He did admit that, given the new CAFE standards, “any material is on the table, due to the activity in many areas.” But Ford’s Friedman emphasized, “We can’t just substitute new materials for old. We try to be material-agnostic, and use any material where it needs to be within a multi-material vehicle.”

Gurit’s Starkey pointed out that given the many forms of resins and reinforcements, composites are “infinitely tailorable for any application,” but deciding on the right mix and the right process, given that huge range of possibilities, can be a challenge.

When asked if lighter cars (i.e., those containing a lot of composites) are as safe as steel-bodied cars, panelists answered yes but pointed out that designs need to provide an adequate level of safety, no matter what the material. Magna’s Pilette pointed out that with more required safety features, such as backup cameras and self-braking systems, which add weight to the vehicle, the pressure is on to reduce it in other systems to compensate yet maintain safety.

As in previous years, the panel concluded that composites make sense for a vehicle when there is a compelling economic business case (e.g., tail gates and cargo doors). Krajewski admitted that elements such as seats lightweighted with a composite frame can yield cascading benefits, including smaller brakes, because dead weight is reduced. Ford’s Friedman emphasized that his company’s decision to use aluminum on its redesigned F-150 truck was driven in part by aluminum’s “infinitely recyclable” nature, implying that composites could do more around recycled content.

The take-away? New, lightweight steel alloys have captured the attention of OEMs and will increase the competitive pressure composites face to a greater degree in the automotive market than many realize.

Keynote speaker Habib Dagher, director of the University of Maine’s Advanced Structures and Composites Center (Orono, Maine), put a positive spin on the situation, however, saying in essence, “if you can’t beat ‘em, join ‘em” — if composites can be combined with other materials to achieve high-performance results, then that’s the way to gain market share.

A wealth of technology

Technical sessions revealed a wealth of new revelations from composites research. A recurring theme was high-rate-capable processing methods for thermoset materials. Koichi Akiyama group leader for automotive composites material development group of Mitsubishi Rayon Co. Ltd. (Tokyo, Japan) described ongoing development of his company’s prepreg compression molding (PCM) technology, in which carbon fiber prepreg material, preformed in a press-forming process, is molded in a high-speed compression press. Akiyama reports that prepreg cure is in the three- to five-minute range, and work continues to reduce it further. PCM reportedly yields a Class A finish and can be modified for comolding with other materials, such as SMC. Akiyama described the redesign and processing of a carbon-fiber decklid for the Nissan R35 GT-R, using PCM. On display at the show, the part is 40 percent lighter than the aluminum part it replaced.

Although state-of-the-art epoxy systems can cure in as little as two minutes, high-volume automotive applications require production output of about 1,000 parts per day, which equates to a one-minute cure time over two shifts. Roman Hillermeier, transportation technology manager, Momentive Specialty Chemicals Inc. (Columbus, Ohio) presented a method capable of producing carbon fiber-reinforced “crash box” components via RTM at that rate, using its fast-curing EPIKOTE epoxy system and multi-cavity tooling. (Crash box components attach to the front-end module of the body-in-white, absorbing energy in event of a crash.) The carbon fiber preforms from the parts were continuously braided on a mandrel, cut and then placed directly in a multi-cavity mold. At nine parts per mold, given an average cure cycle of two to three minutes, the process can produce 1,000 parts in 10 hours. Hillermeier asserted that a cost objective of €5/kg of saved weight could be achieved by using glass or lower-cost, heavy-tow carbon fiber.

Allan James, the composites marketing manager at Dow Automotive Systems (Auburn Hills, Mich.) discussed high-speed resin transfer molding (RTM) processing teamed with his company’s VORAFORCE ultrafast curing epoxy system, as a candidate for high-rate production. For a six-ply test part, featuring 50 percent 24K carbon fiber (by volume) sourced from AKSACA Carbon Fibers (Marietta, Ga.), press cycle time was 1 minute, 21 seconds with acceptable resin conversion (98 percent) and a Tg of 130°C/266°F, using a tool made by Krauss-Maffei Corporation (Florence, Ky.). James says Dow has modeled part preforms and mold filling to avoid fiber displacement and dry spots, and adds an internal mold release to the epoxy resin, to increase cycle time.

Sebastian Schmidhuber, lead R&D engineer at KraussMaffei Technologies GmbH explained the nuances of several high-pressure RTM (HP-RTM) processes. One of the newest, Surface RTM, is capable of producing ready-to-paint carbon fiber exterior parts out of the mold. In this two-step process, a preform is placed in the mold and impregnated with a matrix resin via compression RTM. Next, the mold is opened slightly and polyurethane is introduced into the cavity through a side injector in the mold. The mold is again compressed, creating, after cure, an overmolded Class A surface.

Presenter Klaus Ritter, marketing manager and head of the Center of Excellence for Composites at Huntsman Advanced Materials (East Lansing, Mich.), contended that the differences between compression molding and HP-RTM can be exploited to produce composite epoxy parts tailored for distinct applications. In general, compression molding, which includes expandable epoxy systems and wet compression molding methods, is used to manufacture parts with less complexity, such as door or roof panels. HP-RTM, on the other hand, facilitates greater design freedom, including insert and part integration, for repeatable, medium- to high-volume auto part production. According to Ritter, recently introduced Huntsman epoxy systems shorten cycle times for both processes. Araldite LY 3585/Aradur 3475 is targeted for HP-RTM with a part cure time of about two minutes and an overall production time of four minutes. The company’s new EP System 1 epoxy is designed for wet compression molding processes and delivers a cure time of about one minute and a final part production time of approximately two minutes.

In the area of sheet molding compound (SMC) for body panels, Ashland Performance Materials (Covington, Ken.) Michael Sumner, group leader for SMC, gel coat and marine resin, in the composite polymers – Global Technology Organization, described its design-of-experiments project to improve the mechanical properties of its 39 percent glass-filled, 1.2 density Class A SMC by a minimum of 20 percent, by replacing the material’s unsaturated polyester resin with differing amounts of vinyl esters. Researchers found that a 50 percent blend of a particular vinyl ester with a new, low-profile additive and reactive toughener yielded up to a 40 percent improvement of target mechanical properties without a major compromise in surface finish quality.

SMC also was the topic for AOC Resins (Collierville, Tenn.) Jeff Klipstein, a closed mold technical service specialist, who described his company’s new low-density (1.2) SMC that reportedly has properties equivalent to standard SMC at 37 percent lower mass, and with a Class A surface. This is tricky, explains Klipstein, because adding more glass enhances mechanical properties but tends to degrade the molded surface quality. The new, low-density formulation of polyester and glass fiber is reportedly competitive with aluminum in terms of cost and weight savings. Work is ongoing to further reduce density while maintaining properties and surface quality.

Nanotech sessions

During his overview of carbon nanotube/polymer composites, Brian Grady, the Conoco-DuPont professor of chemical engineering at the University of Oklahoma (Norman, Okla.), said he foresees an increasing role for CNTs as a secondary reinforcement agent for composite parts, rather than as a primary reinforcement. The price of CNTs continues to drop, albeit at a slower rate than predicted. Current prices are about $100/g (almost $300/oz) for single-wall CNTs and about $22.50/kg ($50/lb) for multiwall CNTs, the latter being cheaper because of a much higher yield per pound of catalyst. Grady said if MWCNTs can be manufactured an order of magnitude cheaper, he believes they would replace carbon black in most applications (e.g., electrical conductivity) bacause the properties of the former are superior.

Another nanotechnology paper, presented by David Lashmore, research professor of materials science at the University of New Hampshire (Durham, N.H.) reported the school's researchers are in the preliminary stages of an effort to make continuous boron nitride fiber from boron nitride nanotubes (BNNTs). If successful, the research could pave the way for unique applications of the fibers in automobiles. BNNTs and CNTs have similar tensile strength, but unlike CNTs, which begin to degrade at about 400°C/752°F, BNNTs maintain their structural integrity up to 900°C/1652°F and have piezoelectric properties.

A doctoral student at Michigan State University, Keith Honaker described research that involved the design and manufacture of a six-layer HDPE automotive fuel tank with incorporated graphene nanoplatelets, which achieves an impermeable barrier. The tank reportedly complies with the California Air Resoures Board (CARB) for zero evaporative emissions, and work is proceeding on the best methods for dispersing the graphene material onto or into the HDPE polymer.

Thermoplastic autocomposites

Thermoplastic composites were featured in several sessions. One of the challenges for thermoplastics in automotive applications is meeting part stiffness requirements at elevated temperatures — typically 90°C/194°F. DuPont Automotive (Wilmington, Del.) Paul Kane, who leads DuPont’s performance materials North America advanced development automotive light-weighting solutions team, presented a review of high glass transition temperature (Tg) polyphthalamides (PPAs) and their use as overmolding resins with stamped, continuous glass fiber polyamide inserts. Kane reported that at 90°C, a 50 percent glass-reinforced PPA with a Tg >100°C/212°F has almost twice the modulus of a 50 percent glass-filled PA 6/6. Kane reported results of a study that found crossmember beams comprising stamped, 1.5 mm/0.06-inch-thick, 66 percent continuous glass sheet and polyamide overmolded with PPA had almost 30 percent higher stiffness at 90°C than the same beams overmolded with PA 6/6, as evaluated by a three-point bending test.

Presently, injection molded, glass fiber-reinforced parts are most commonly manufactured from thermoplastic pellets that contain strands of chopped glass fiber. Mark Paddock sales manager for Arburg Inc. (Lossburg, Germany), provided details of a project entailing long fiber injection molding from continuous glass rovings. The glass roving is paid out into a side feeder, where it is cut into fiber strands in lengths of 15 to 50 mm (about 0.6 to 2 inches). The project used a 275-ton injection molding machine equipped with a specially designed 60-mm/2.36-inch two-stage screw, which carries out both melting of the resin and homogenization and blending of the fibers into the melt. Arburg claims that analysis of a sample airbag housing made from long-fiber granulate showed that only 30 percent of its fibers were longer than 2 mm/0.086 inch. Another housing, made using Arburg’s method, showed that 50 percent of its fibers were longer than 2 mm, resulting in far better properties. Development and optimization of the process is ongoing.

A twist on long-fiber technology was the focus for Alexander Roch scientific staff member and project director in the polymer engineering department at Fraunhofer Institute for Chemical Technology (ICT) (Pfinztal, Germany), who discussed the automotive lightweighting potential for injection molded, long glass fiber-reinforced integral foams using “breathing mold” technology. Two material systems, PP-LGF and PA6-LGF, were tried, coupled with chemical blowing agents and a physical blowing agent, at both low and high pressure. A gas-loaded melt is injected into a cold mold, forming a solidified skin with a foamed core throughout the entire mold cavity, regardless of part complexity. The sandwich approach saves material in the neutral-axis area and provides high bending stiffness at a low surface weight, which, Roch claims, could work for large parts, such as door panels, spare wheel wells, seat shells and backrests, underbody assemblies and instrument panel supports.

Vasant Pednekar, senior engineer, application development in high-performance materials, at LANXESS Corporation (Pittsburgh, Pa.) described an interesting project, during which a prototype airbag housing was produced for a Tier 1 integrator. The goal was to reduce the weight of the existing plastic part by 35 percent, yet maintain its performance — a tall order. After extensive simulation and topological optimization modeling, Lanxess’ woven preconsolidated glass/thermoplastic TEPEX laminate sheet was chosen to carry loads, with the sheet material overmolded in an injection molding process with glass-reinforced nylon to form the part. Pednekar says a chemical bond was achieved between the two materials during a cycle of less than one minute. Further work will be done as the concept moves to production.

Testing and test results

If more automotive parts are to be made with composites, trained technicians and an infrastructure to enable repairs will be a key element of success. To that end, Louis Dorworth, division manager, direct services, at Abaris Training Resources Inc. (Reno, Nev.) gave a one-hour, detailed session on inspection methods to locate damage, and specific methods to affect a repair, using tapered-scarf repairs as the preferred method. Dorworth believes that body-shop technicians can be trained in the correct techniques using the methods currently in place for aerospace repair experts.

Finally, applications and testing engineer Mike Mathews of PCCR USA Inc. (Carpentersville, Ill) presented a summary of a study assessing possible material solutions for reducing fatigue cycling damage and crack propagation in composite parts. In particular, the study compared the critical damage/recovery properties of test coupons made from carbon fiber-reinforced vinyl ester resin, modified with core shell rubber (CSRVE) to fiber-reinforced samples made from a low-viscosity epoxy, a standard vinyl ester and a standard polyester. The company found that CSRVE samples that were deformed during ASTM D790 flexural testing returned to their original shape when the samples were heated above their Tg of 130°C/266°F for three minutes, and they retained about 80 percent of the resin’s original flexural modulus. Comparatively, epoxy samples subjected to the same test showed slight, permanent deformation, and samples made from standard polyester shattered. Study results imply that CSRVE composites could be a promising material solution in applications entailing high fatigue and stress loadings, such as structural automotive parts, says Mathews.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreRead Next

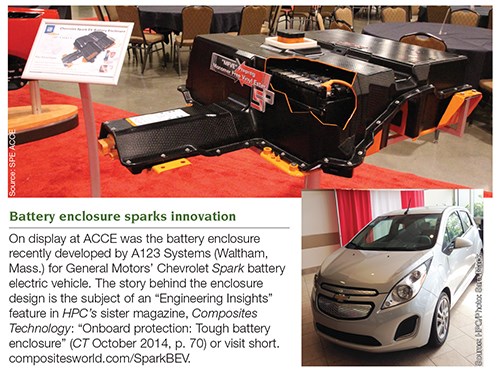

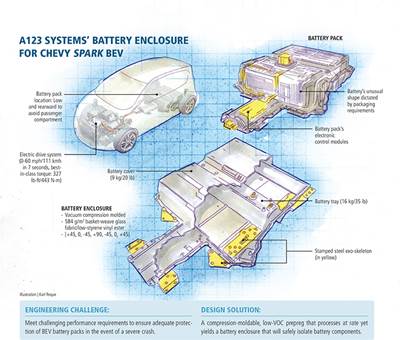

Onboard protection: Tough battery enclosure

Unique composite laminate provides crash protection for electric vehicle’s battery, occupants and first responders.

Read MoreOnboard protection: Tough battery enclosure

Unique composite laminate provides crash protection for electric vehicle’s battery, occupants and first responders.

Read MoreA123’s Better Battery

Last week we wrote about the potential for some significant developments in batteries, and lo and behold, on Tuesday A123 Systems announced, well, what its CEO David Vieau describes, with what we can only describe as a bit of hyperbole, but describes nonetheless, as follows: “We believe Nanophosphate EXT is a game-changing breakthrough that overcomes one of the key limitations of lead acid, standard lithium ion, and other advanced batteries.

Read More