Automated Preforming, Part 4: Drapability Testing

Textechno discusses how this test works, the new German test standard and its benefits for composites

This is part four of a seven-part series about preforming. For more on this series, click the links below:

part one, part two, part three, part five, part six, part seven.

Also, don’t miss the printed version of this series:

Preforming Goes Industrial, Part 1 and Part 2.

In this blog, I present the DrapeTest automated test equipment for characterizing the drapability of woven and noncrimp fabrics and the formation of defects during draping and forming. Now a DIN-Spec standard in Germany, its developers see the benefit in having an international standard. In the meantime, this test provides a means for comparing fabrics to be preformed as well as data that can be used in simulation and analysis.

Textechno (Mönchengladbach, Germany) is a pioneer in developing new test methods and instrumentation for textile testing. More recently, the company has added testing services. “We have had requests to provide this for many years, but we didn’t want to compete with the institutions that were also our customers,” explains Textechno managing director Dr. Ulrich Mörschel. However, with increased demand, the company finally conceded, now offering the following services specifically for composites:

- Characterization of fibers and tows

- Drapability of fabrics

- Fiber-to-matrix adhesion testing

DrapeTest Development

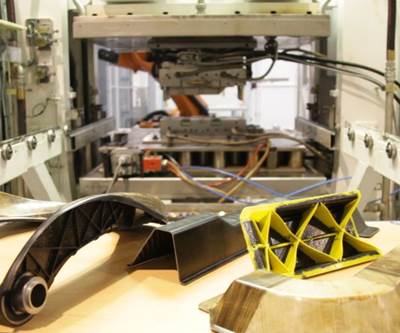

Development of the automatic drapability tester began in 2011 with an early prototype from noncrimp fabric (NCF) producer SAERTEX (Saerbeck, Germany) and a working group of German partners including Faserinstitut Bremen (Fibre), Institut für Textiltechnik (ITA) of RWTH Aachen University, technical fabrics producer J. Schilgen (Emsdetten), composites fabricator Haindl Kunststoffverarbeitung (Bremen) and Textechno. Their objective was to automatically characterize the drapability of woven and noncrimp fabrics and to analyze the formation of defects during draping and forming.

The group’s efforts were recognized by the JEC Europe show in 2012, which noted that as the production of 3D fabric-reinforced composite parts becomes increasingly automated, detection of defects such as gaps, loops or wrinkles during draping becomes even more important.

How Does DrapeTest Work?

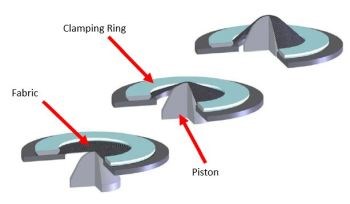

The DrapeTest equipment combines the measurement of the force required for forming with an optical analysis of defects by means of image analysis. A flat circular sample of the fabric to be tested is deformed from below using a motor-driven, rounded piston. The fabric sample is held with a clamping ring and the tester is connected to a Windows-based PC for setting test parameters and data acquisition/storage.

A force transducer inside the piston measures the force required to deform the sample. Both maximum and average force is measured up to a maximum elevation of 100 mm. Elevation steps can be programed—a test could contain the elevations 0, 20, 40, 60, 75, 85, 95 mm.

DrapeTest uses a rounded piston to deform a circular sample of fabric held by a clamping ring. Force required to deform the fabric is measured at set elevations up to 100 mm—shown here as 0, 40 and 80 mm.

SOURCE: Textechno.

Optical Defect Detection

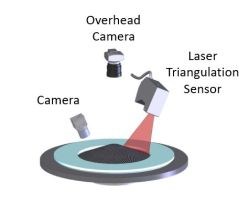

In contrast to the original SAERTEX prototype, DrapeTest equipment now features optical defect detection. A high-resolution camera inspects the sample for fine-scale defects (e.g., gaps, changes in fiber orientation). The camera can be positioned in three axes and the sample can rotate by more than 360 degrees. The angle range to be inspected as well as the number of pictures to be taken are test parameters that can be varied.

|

DrapeTest uses a multi-tool optical system to defect both fine-scale (gaps, fiber orientation errors) and large-scale defects (wrinkles).

SOURCE: Textechno

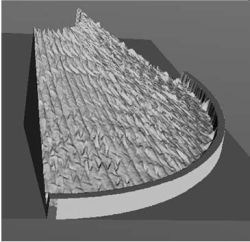

The camera obtains images in 2D only, thus, an additional laser-triangulation sensor is used in order to define the surface morphology of the sample before and after forming. The sample is rotated while the laser sensor scans the sample continuously, enabling DrapeTest to also detect large-scale defects such as wrinkles.

A second, medium-resolution camera oriented above the sample (overhead camera) records images of it before and after the test. A typical test with several elevation steps takes 5-15 minutes per sample.

|

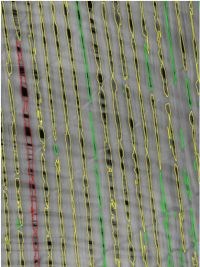

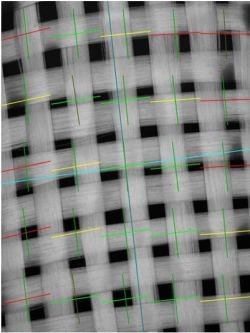

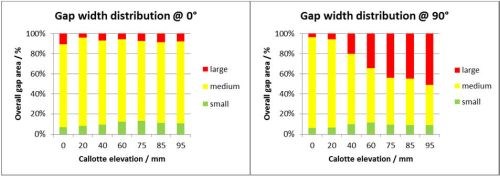

Results of the gap detection after an elevation of 95 mm at 0 degrees (top left) and 90 degrees (top right) position. Wide gaps are colored red, medium gaps yellow and narrow gaps green. At the 90-degree position, more wide gaps have occurred compared to the 0-degree position, which corresponds to the graphed data at the bottom.

SOURCE: Textechno.

Test results

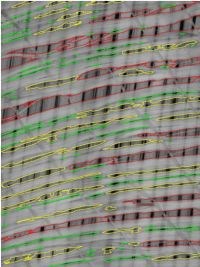

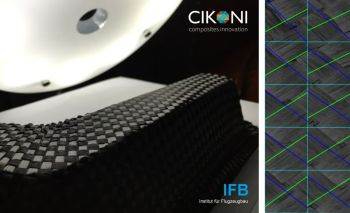

From the pictures taken by the initial, 2D high-resolution detail camera, the image analysis software determines width, length and area of gaps, as well as the degree of fiber misalignment. Area and volume of wrinkles are measured using the laser-triangulation sensor. With the overhead camera, the overall deformation of the original circular shape of the specimen can be measured and quantified via the image analysis software. Although image analysis on carbon fiber fabrics is tough because of their high reflectivity, the detection of gaps and misalignments works well for these specimens, too.

A complete description of the test fabric’s drapability can be derived from the test data. The quantitative results of DrapeTest are reproducible and can be used as input for numerical simulations or to verify existing material models.

|

DrapeTest results showing classification of fiber misalignment in a glass fiber is woven fabric (left) and 3D model generated from data of the laser-triangulation sensor taken on a carbon fiber sample (right).

SOURCE: Textechno

DIN Spec 8100

Thus, the DrapeTest equipment has been advanced from the original development in 2012-2013. Work also continued toward a standardized test method, which would allow a true comparison of fabrics. The group continued forward, led by Textechno, SAERTEX and Fibre, but now with Deutsches Institut für Normung e.V. (DIN), known in English as the German Institute for Standardization (Berlin) as a key member and new partners Groz Beckert KG (Albstadt), which provides textiles equipment, development and training courses, and its research arm FTA Albstadt.

In November 2015, the DIN Spec 8100 "automated drapability testing for woven and non-crimp fabrics used in continuous fiber reinforced plastics" was finalized and adopted in Germany. It subsequently received a DIN Innovation Award.

Now there is an objective to create an ISO standard on the basis of DIN Spec 8100. “We’ve been talking to ISO and they are interested but would extend it to all types of fabrics,” says Textechno managing director, Dr. Ulrich Mörschel.

Benefits to the composites industry

Mörschel and the other DrapeTest partners agree that its main benefits include the ability to define drapability of fabrics for composites forming and compare, in a standardized, reproducible way, one fabric to another. “Parts manufacturers can now evaluate and select the best raw material for their processes,” Mörschel notes. It also allows manufacturers, designers, researchers and material suppliers to communicate efficiently, using well-defined data and benchmarks. Mörschel also sees value in using DrapeTest when developing new textile products. “For example, machine settings such as stitching yarn tension can have a strong influence on the drapability of noncrimp fabrics,” he explains. “Using DrapeTest will allow material producers to look at how the formation of gaps is reduced or increased.” Finally, the data obtained is useful in material simulation models. “Fabric is commonly modeled as a continuum,” he points out, “allowing you to see the formation of wrinkles, but not gaps or fiber undulation.”

For more information, DrapeTest equipment will be exhibited in Textechno’s booth (B52) during CAMX 2017 (September 11-14, Orlando, Florida). Dr. Mörschel will also be available to discuss the latest machines unveiled earlier this year that can do dynamic tests for fiber-to-fiber friction and for fiber-to-matrix adhesion.

Related Content

Biesterfeld gains composites distribution rights from Saertex

Under the new strategic distribution partnership, Biesterfeld will be the official sales partner for various Saertex material products to the German market.

Read MoreDesigning an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

Read MoreUltra-light woven reinforcement fabrics enhance space-grade parts

CAMX 2024: TeXtreme is showcasing its TeXtreme 0/90 woven fabrics, demonstrated through customer Kerberos Engineering’s satellite solar array.

Read MoreRWC completes prototype radome using Renegade NCAMP-certified composite

Completed prototype for Georgian Aerospace uses a low-dielectric epoxy prepreg on quartz fabric, which has passed radio frequency testing with results equivalent to traditionally higher-cost, low-dielectric matrix options.

Read MoreRead Next

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

Read MoreAutomated Preforming, Part 5: Holistic Quality Optimization

Simulation and testing key to integrated approach for optimization of automated preforming, offering time and cost savings as well as basis for automated quality inspection.

Read MoreCutting engine weight via thermoplastic composite guide vanes

Greene Tweed replaces metal stator vanes with its DLF material co-molded with a metal leading edge that meets performance, cost and high-rate production targets while cutting 4 kg per engine.

Read More