Preforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

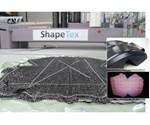

Complex, tailored preforms in minutes

The Quilted Stratum Process was developed by a partnership that included French composites suppliers, automakers and Nantes, France-based Cetim. It can feed, cut and assemble multi-thickness, multi-oriented unidirectional thermoplastic tapes into tailored preforms in 40-90 seconds. It can produce complex parts with molded-in holes and inserts in cycle times of 1-2 minutes. Source | Cetim

Editor’s note: See the secoond part of CompositesWorld’s series on composites preforming here: Preforming goes industrial: Part 2.

In the race to reduce the cost and cycle time of composite parts, automation has successfully transformed cutting, molding and machining into processes more suited to industrial production. However, when CW last looked at the manufacturing step of preforming — the process of preparing the reinforcements used to mold three-dimensional (3D) parts — it was still a production bottleneck: a complex, step-intensive, often manual process (see Structural preform technologies emerge from the shadows). In the three years since, the emerging technologies that could automate preforming have proliferated and are finally reaching maturation. In Part 1 of a two-part series on the topic, CW looks at a wide variety of new commercially available systems that benefit from robotics combined with preform building processes adapted from automated tape laying (ATL) or automated fiber placement (ATL) technology.

Enclosed automated fiber placement cell

In 2015, Broetje Automation (Rastede, Germany), a supplier of specialized production systems (e.g., handling, assembly, machining) for the aerospace industry, introduced its STAXX Compact 1700 automated AFP workcell for near-net shape preforms (Fig. 1). “When we started development, there were many companies focused on automated fiber placement for aerospace,” says Dr. Matthias Meyer, VP of Broetje Automation’s subsidiary BA Composites GmbH (Grenzach-Wyhlen, Germany), “So we focused on automotive and industrial parts, and also on using a low-cost input material — towpreg.” This also motivated the unit’s design as an enclosed, climate-controlled cell with a footprint of 3m wide by 6.5m long by 3m high — a compact system that could be put into production quickly in practically any facility.

Fig. 1. Cored preforms for auto parts at 100,000 per year

The STAXX Compact 1700 automated fiber placement (AFP) workcell, developed by Broetje Automation (Rastede, Germany), can lay up preforms from towpreg or slit tape at 30 kg/hr, with integrated sandwich core and/or inserts, supporting production of as many as 100,000 automotive parts/yr. Source | Broetje Automation

Meyer, who defines towpreg as a carbon fiber roving impregnated with a typically epoxy matrix, notes that the STAXX also can process dry fiber with binder applied ready for subsequent liquid molding, or a thermoplastic product, which, after preforming, is simply thermoformed into finished parts. (STAXX also can process slit prepreg tape because it can remove the backing film, but its use increases cost because it requires post-prepreg slitting operations).

Comprising two magazines, each housing 16 spools for towpreg feed, an AFPhead with a compact clamp/cut/restart unit and a rotary table, the STAXX Compact 1700 offers a material feed rate of 40 meters/minute, a layup rate of 30 kilograms/hour, and a pallet size (part layup area) of 1,525 millimeters by 900 millimeters. It also offers a scrap rate potentially below 5% vs. the 50% that Meyer asserts is typical in textile preforming for parts of this size. The rotary table and buildup of layered blanks appears similar to Dieffenbacher's (Eppingen, Germany) Fiber-forge RELAY Station. Meyer contends that RELAY is using automated tape laying (ATL) with ultrasonic spot-welding, not AFP with continuous compaction, and that the STAXX rotary table also can accommodate 500 millimeters of z-directional travel, which enables integration of sandwich core and specialized inserts.

“We use a zero-point clamping system for just this reason,” Meyer notes, adding that, either manually or via automated pick- and-place robot, “you can take the pallet out and equip it very accurately with inserts, and then put it back into the cell with tolerances below 0.1 millimeter.” He points out that although this is new for AFP, it is considered standard in the metal-cutting industry, as is much of the CNC control designed into STAXX. For example, “It has two bays,” he says, “so that you are loading one part while laying up another simultaneously, in order to maximize throughput.”

Meyer also claims a big advantage in design freedom with regard to fiber orientation. “STAXX can place fiber at any angle between 0° and 180°, in increments of 0.01°,” he claims. Parts demonstrated, thus far, include automotive tunnels, floors and B-pillars. “We have shown that we can supply ... B-pillars from a single machine for a luxury car at 100,000 units per year,” Meyer contends. “We can also make aerospace parts, like ribs, clips and brackets, as well as industrial parts.”

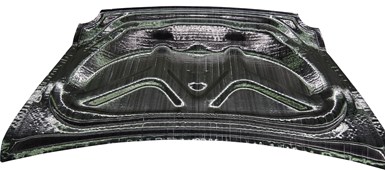

ATL at 10-15 seconds per layer

FILL Gesellschaft (Gurten, Austria) supplies innovative machinery for production in metals, plastics, wood and fiber-reinforced composites. “Preform automation is one of our main fields,” says Wilhelm Rupertsberger, head of FILL’s composites competence center, noting systems developed for BMW and Audi, including a machine for the carbon fiber-reinforced plastic (CFRP) rear wall of the new Audi model, as well as equipment for CFRP wheels at Tier 1 suppliers to other companies. “All of these machines automate preforms for RTM,” he adds.

Fig. 2. Picks, places and consolidates 4-5 layers per minute

The MultiLayup System from FILL Gesellschaft (Gurten, Austria) feeds UD tape from two sides to a central station where a vacuum gripper with integrated heating picks, places and consolidates each layer’s tapes to build preforms at 10-15 seconds per layer. Source | Fill

Although FILL has sold a number of units for cutting, stacking and hot-drape forming unidirectional and noncrimp fabric reinforcements into composite preforms, its latest development is an adaptation of ATL. The MultiLayup System (pat. pend.) uses dual arrays of vacuum rails to convey tape from two magazines of up to 16 reels each. Both material feeders unroll and cut the designated tape from each reel to a tailored length, as determined from the part’s CAD file analyzed by FILL process software.

“Connection between CAD data to CNC control is one of our strengths,” explains Rupertsberger. The cut tapes required for a given ply in the preform are then transferred by a vacuum gripper system to a segmented rotary deposit table with 100 mm of z-axis movement. The vacuum gripper’s integrated heating strips join/consolidate each ply of tapes to the next layer on the table, producing a tailored near-net shape preform (Fig. 2). The system accommodates parts up to 2 meters by 2 meters, which Rubertsberger claims readily handles automotive parts, including roofs, hoods and backwalls at the upper limit of this range.

Rupertsberger cites an unusually short cycle time of 10-15 seconds per layer. “The dual feeders effectively double the rate of material delivery to the pick-and-place station,” he explains. More importantly, the vacuum gripper collects and places each layer’s tapes simultaneously, instead of one at a time. “We can also reduce the waste by integrating nesting of cut tapes digitally into the process,” he says, adding, “We also check the direction of the fiber and the shape of the completed preform.”

In addition to the MultiLayup System, FILL is working with ENGEL AUSTRIA GmbH (Schwertberg, Austria) to develop thermoplastic tape preforming. “Our equipment makes the layup, and ENGEL AUSTRIA GmbH has the machine to add the injection material and thermoform the part,” says Rupertsberger. For automotive, the unidirectional tapes use polyamide (PA) as a matrix. He explains that these parts can use carbon fiber, but it is expensive and, therefore, important to place it with precision only where needed. “Our machine feeds, cuts, positions and consolidates the tapes to create a tailored organosheet inline, achieving the benefits of injection molding with the properties of composites,” he claims. “We are exploring this technology for cycle time reduction and also for the recyclability of parts,” he adds, but also notes, “Parts manufacturers would rather have the fiber and matrix already together in a semipreg thermoplastic material in order to simplify and avoid a chemical process in the line.”

Read more in the blog “Automated Preforming, Part 7: Fill Gesellschaft”.

40-second preforms, 90-second parts

The Quilted Stratum Process (QSP) focuses squarely on thermoplastic tapes, pultruding them inline and then assembling them into preforms for use as inserts in a thermoforming process. Started in 2013, with a pilot production line completed in 2015, QSP is a French development led by R&D facility Cetim (Nantes) in partnership with suppliers Pinette Emidecau Industries (Chalon sur Saône), Compose (Bellignat) and Loiretech (Malville) and local government Région Pays de Loire.

QSP feeds, cuts and assembles multi-thickness, multi-oriented inputs into tailored preforms in 40-90 seconds. Fast, robotic transfer (<5 seconds) then moves preforms through a two-step preheat before thermoforming them in a 500-MT Pinette press with a 2,000-bar, 0.4-liter shot Krauss-Maffei (München, Germany) injection unit for overmolding, using a 200-kilowatt RocTool Inc. (Le Bourget du Lac, France) rapid heat/cool induction system.

The line begins with thermoplastic pultrusion of glass or carbon fiber unidirectional (UD) tape at the right thickness (1.5-3.0 millimeters) and width (100-300 millimeters) for the process. “With thin tapes, you need three to four layers in the preform,” explains Franck Bordellier, lead QSP development engineer at Cetim. “We’d rather have these already plied in the tape.” The goal is to produce tape at a cost of €3/kg (US$3.27/kilogram). “Pultrusion can reduce cost because it is a continuous process,” says Bordellier. “If we run the line at 3m/min we can beat glass fiber/polyamide organosheet at €7/kilogram [US$7.64/ kilogram].”

This tape is fed directly into the Pinette-supplied cutting cell and cut while at, using an ultrasonic (UT) technology developed by Sonimat (Lencloître, France) that operates at 400 mm/sec. Cut tape patches are then transferred to storage or the preform assembly module, which uses a patent-pending tape placement concept to a x patches with UT welding. “It is very efficient because it is more of a parallel vs. serial build process.”

Assembled preforms exit via conveyor and are moved by robot into a conduction oven, which heats the inside of the preform, and then into an infrared (IR) oven which heats the outer surfaces. “Conduction provides maximum calories inside the preform,” says Bordellier, “which allows us to put a lot of heat into higher thickness areas without degrading the lower thickness areas.” From the IR oven, located just outside the press, preforms lose only 15°C before thermoforming begins. “The preform’s thermal profile has a direct effect on part performance,” notes Bordellier.

Parts are demolded on the opposite side of the press by a robot with needle grippers from Schmalz GmbH (Glatten, Germany). Bordellier describes the line’s process control, “We have integrated a thermal camera for IR heat control, a laser system for preform placement and an optical system for quality assurance through the process.” He notes that QSP has demonstrated hundreds of parts. Among them is the L-shaped, multi-material automotive seat structure, developed with Faurecia, which integrates 13 patches of 1.5-, 2- and 3-millimeter thick organosheet and UD tape into a preform in 40 seconds. The 2.5- to 3-milimeter thick part, with integral plastic and metal fittings, is formed in a one-shot, 60-second molding cycle.

Read more in the blog “Automated Preforming, Part 3: Quilted Stratum Process”.

Fig. 3. Quick-change head processes multiple materials quickly

Preforming systems developed by Compositence (Leonberg, Germany) can process towpreg, dry fiber and thermoplastic tape, using an exchangeable, quick-release AFP head to produce as many as four net-shape preforms simultaneously, in one minute. Source | Compositence

Four parts/minute and multifunctional tow

Although Compositence (Leonberg, Germany) has developed an AFP-based method to produce near net-shape preforms, it has also moved beyond, working with BMW to develop what it calls multifunctional tow, which dramatically boosts drapability and material throughput. The main elements of its system include a spool creel, 2D (gantry) or 3D (robot) manipulating system with exchangeable, quick-release AFP head and a rotary table on a linear rail (Fig. 3). Its newest system, ready for production later in 2017, will lay up as many as four preforms (e.g., 1.25 meters by 0.75 millimeters) simultaneously, in 1 minute. Both systems can handle towpreg, dry fiber and thermoplastic tape.

Fig. 4. Millions of parts per year and 25% less scrap

Working with BMW and SGL, Compositence has developed stitched, dry fiber multifunctional tow and demonstrated preform production at rates up to 250 kg/hr — 3.5 million parts/yr, — besting NCF with equal or better drapability and resin flow in subsequent molding but 25% less scrap. Source | Compositence

Thomas Dobiasch, head of sales at Compositence, says conventional AFP typically uses 0.25-0.5-inch (6.35-12.7-millimeter) wide tapes, derived from the process’ aerospace origins. Developed for automotive parts, the Compositence system uses tapes ≥12-millimeters wide with 150-600 g/m2 fiber areal weight because, says Dobiasch, “placement of narrow materials takes too long. For us, the speed of the preform layup must be in the same range as the molding machines, which for injection molding is 1 minute.” However, he cautions, “Wide tapes can produce more waste for certain types of parts. You must tailor your process for the part you are making.”

In pursuit of speed, Compositence has patented its edge fixation technology for AFP. “We fix the fibers only at the beginning and end of placement,” says Dobiasch, explaining that the AFP head lifts slightly up to fly freely, “accelerating across the layup in between, which speeds up productivity.” However, this edge fixation technique cannot be used with towpreg, because it requires continuous compaction to avoid trapping air in the layup.

Another key driver in preforming productivity is drapability. “Our draping capability must be the same as noncrimp fabric [NCF] or better,” notes Dobiasch. Since 2010, Compositence has worked on AFP preforming with BMW (Munich, Germany) and SGL Group (Wiesbaden, Germany). “With them, we have developed what we call multifunctional tow, where multiple rovings are fixed together with a kind of textile process,” he explains (Fig. 4).The stitching binds the tows to maintain precise width — typically 46 millimeters for dry fiber — and also aids resin flow vertically through the fibers, crucial in the next step, either resin injection or infusion.

“The fibers are not blocked from moving layer to layer as they are in stitched fabric,” Dobiasch explains, “so drapability is very good and confirmed by BMW as being the same or better than NCF. They have also verified the improved resin flow.” He concedes the material does require more time and cost to produce vs. towpreg, “but it is better to give the material some functions, and you then get cash back during the processing via less scrap and better cycle time in wet compression molding and RTM.”

Dobiasch claims a 25% reduction in scrap vs. NCF due to AFP’s net shaping ability compared to cutting waste with fabric. He adds, “We have also demonstrated with BMW that we can preform 3.5 million parts per year on one machine with an output of 250 kg/hr.”

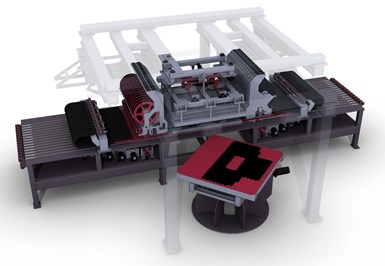

Back to the future, Fiberforge 4.0

The original automated tape/fiber process was the Fiberforge RELAY Station, mentioned earlier, which CW reported on as early as 2004. A spin-off from high mileage/low-weight automotive development, it made its own tapes from large-tow carbon fiber or glass rovings and melted thermoplastic pellets (e.g., nylon), orienting the fiber into a semi-consolidated sheet, or tailored blank, which was then heated and pressed into a composite part. In 2008, it produced a unidirectional glass/polyethylene military backpack frame with integrated ribs in 70 seconds, with reported production of 20,000 units.

Fig. 5. More versatile version of a pioneer preforming process

Eppingen, Germany-based Dieffenbacher’s new Fiberforge 4.0

preforming system boasts material throughput of up to 490 kg/hr, layup speed of less than 1 second per course and the capacity to combine up to four different types of tape in one part.

Source | Dieffenbacher

Although Fiberforge was liquidated in 2013, Dieffenbacher North America Inc. acquired the RELAY technology and has continued its development. Dieffenbacher’s Fiberforge RELAY Station, capable of parts measuring 2 meters by 2 meters and laydown rates to 150 kilograms/hour in 2014, has evolved into Fiberforge 4.0 (Fig. 5). is more recent development boasts material throughput of 490 kilograms/hour with a layup time of less than 1 second per course, and it has the ability to combine as many as four types of tape in one part. Further, version 4.0 reportedly can interface with other Dierrenbacher automated systems to produce more than 1 million parts/year from a single production line. “Fiberforge 4.0 is a game changer,” contends Dieffenbacher’s director of technology and business development Matthias Graf, “and we expect that it will bring a breakthrough for composites in the automobile industry.”

More to come

The examples mentioned here are not exhaustive. Other early preforming pioneers, such as Coriolis Composites (Queven, France), also are at work on faster evolutions of AFP for automotive preforms, including glass fiber/polyamide prepreg tape loops, which are overmolded to produce composite engine mounts. And new players continue to emerge. Voith Composites GmbH & Co. KG (Garching bei München, Germany), for example, launched its Voith Roving Applicator at JEC World 2017 (March 14-16, Paris, France).

More detailed discussions of additional players and other processes, plus news about standardized drapability testing, preform simulation software and specific solutions for aerospace and wind energy structures, can be found online in the CW Blog Automated Preforming series.

All that to say this: Given the ongoing activity — already commercial and potential — it’s already clear that preforming is unlikely to remain a composites production bottleneck. And in Part 2, CW will explore new solutions for forming fabrics, 3D and continuous processes and the latest in tailored fiber placement (TFP) technology.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePlant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreRead Next

Preforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)