Out of Autoclave

Update: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

WatchNational Composites Week: Top 20 stories in the last decade

As we celebrate National Composites Week, we’ve collected our top content over the last ten years.

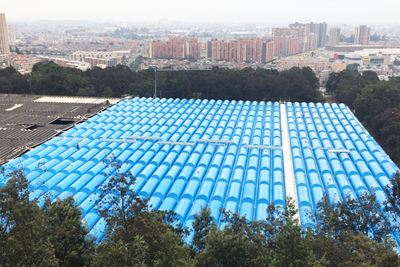

Read MoreSoling, Magnum Venus Products partnership produces LRTM composite domes

Incorporating the LRTM process enabled Soling to produce the largest LRTM part by volume manufactured in Colombia.

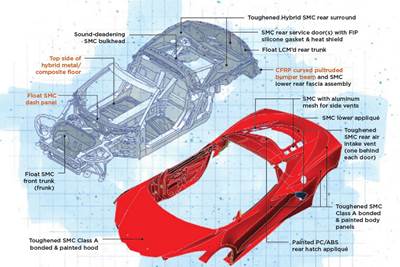

Read MoreComposites-intensive masterwork: 2020 Corvette, Part 2

Innovative composite materials trim mass, costs and noise on the high-volume mid-engine sports car.

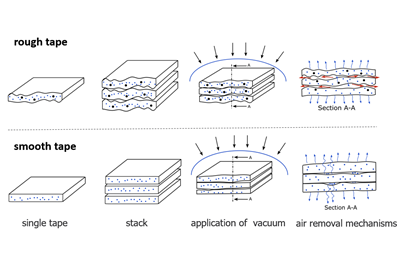

Read MoreTPRC investigates AFP in-situ consolidation alternative

The two-step process involves deposition of thermoplastic prepreg via AFP, followed by vacuum-bag-only (VBO). Research has already been completed in the qualitative stage.

Read MoreCAMX 2020 exhibit preview: Hexcel

Hexcel is showcasing its resins, thermoplastic UD tapes, epoxy prepregs and additive manufacturing technology.

Read MoreRecycled thermoplastic composite rotorcraft access panel takes flight

Designed as part of the TPC-Cycle program, the flight-tested panel demonstrates a lighter, cost-effective, sustainable thermoplastic composite application.

Read MoreLeonardo and CETMA: disrupting composites for lower cost and environmental impact

Italian OEM and tier supplier Leonardo works with CETMA R&D to develop new composite materials, machines and processes, including induction welding for in-situ consolidation of thermoplastic composites.

Read MoreCAMX 2020 exhibit preview: AGC Chemicals

AGC Chemicals Americas' mPLASTICS are new fluoropolymer-modified compounds to enhance the performance of carbon fiber-reinforced thermoplastic composites.

Read MoreElectroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

Watch