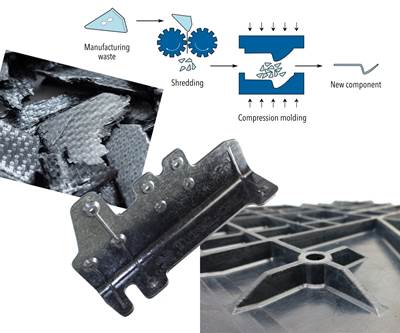

A demonstrator of the recycled carbon fiber/PPS access door panel. Source | TPAC

GKN Aerospace (Redditch, U.K.) reported in June 2020 that with the successful flight test of Bell Flight’s (Fort Worth, Texas, U.S.) V-280 Valor military rotorcraft, several of its thermoplastic composite (TPC) components had taken to the skies. Among these components were two integrally-stiffened, compression-molded, thermoplastic composite access panel doors manufactured from recycled waste material via the TPC-Cycle program led by the ThermoPlastic composites Application Center (TPAC, Enschede, Netherlands) and Saxion University (Enschede, Netherlands) (read CW’s previous coverage on the four-year TPC-Cycle program).

The new recycled panel door was designed to replace a carbon fiber/epoxy part manufactured via hand layup, with the goals of reducing part weight as well as manufacturing cost and cycle time. The new component was designed and tested by GKN Aerospace, and manufactured by the TPAC, in collaboration with the ThermoPlastic composites Research Center (TPRC, Enschede, Netherlands). The access panel doors are comprised of Toray Advanced Composites (Nijverdal, Netherlands) carbon fiber-reinforced polyphenylene sulfide (PPS), reclaimed from consolidated waste generated during the production of the rotorcraft’s TPC V-tail empennage components, which are also designed and manufactured by GKN Aerospace.

The recycled TPC access panel door boasts weight savings of 9% compared to the original part, as well as significant production cost savings.

TPAC’s proprietary re-manufacturing process involves three main steps: Shredding the waste into centimeter-long flakes, simultaneous heating and low-shear mixing and compression molding the part in an isothermal mold.

According to project partners, the demonstrator component offers weight savings of 9% compared to the original part, largely due to the thermoplastic material’s processability, which enables the integration of stringers for geometric stiffening. The orientation of the stringers was chosen to distribute stresses more uniformly over the product, resulting in material reduction and weight savings. Material optimization was also achieved by using reclaimed materials, reducing overall waste.

Significant production cost savings were achieved through the use of reclaimed materials, which eliminated the costs associated with new materials. In addition, the original process required hand layup and use of an autoclave; the out-of-autoclave (OOA), compression molding process involves an isothermal mold, fast demolding and near-net-shape manufacturing to maximize cost efficiency and overall manufacturing cycle time.

“The current project underlines the role of applied research involving the total value chain in driving innovations from first idea to an industrially viable and tested product in record time,” says Ferrie van Hattum, TPAC’s scientific director.

The Bell V-280 Valor in flight. Source | GKN Aerospace

In addition to meeting weight and cost savings goals, the application and process also demonstrate a step toward more sustainable manufacturing. Preliminary results of an ongoing life cycle analysis (LCA) performed by Saxion and TPAC show significant CO2 reductions when using this material, the manufacturing process — mainly due to the part’s lower weight — the use of recycled material and the use of an isothermal mold in an OOA process. According to project partners, application of reclaimed fiber reduced the CO2 output from production of new materials and significantly increased the part’s buy-to-fly ratio. The shredding, mixing and compression molding stages of the process also are said to reduce energy consumption by eliminating the autoclave from the previous thermoset composite production process. Thermoplastic composites also produce negligible amounts of harmful volatile organic compounds (VOCs) during processing compared to thermoset-based composites.

The TPAC says the manufacturing process used for this application looks like a promising solution for other non-structural aerospace products, and its short cycle time may make it viable for end markets that require higher volume throughput. Work is ongoing to evaluate the production process for serial production, as well in-depth cost and environmental impacts, and quality control and inspection implications. A feasibility study is also being executed to see if the applied approach and recycling route can be applied to other aerospace applications such as non-structural fairings, covers and system brackets.

Additional TPC-Cycle project partners include Nido Recyclingtechnologie (Nijverdal, Netherlands); Cato Composites (Rheden, Netherlands); Dutch Thermoplastic Components (Almere, Netherlands) and the ThermoPlastic Composites Research Center (TPRC); Regieorgaan SIA, part of The Netherlands Organisation for Scientific Research (NWO, The Hague, Netherlands).

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreThermoplastic components successfully flight tested on Bell V-280 Valor

The components were manufactured for Bell by GKN Aerospace for the V-280 Valor tiltrotor.

Read MoreRecycled thermoplastic composites for production

Multi-year R&D at ThermoPlastic composites Applications Center (TPAC), TenCate and Clean Sky 2 demonstrate economic advantage of serial production using recycled materials.

Read More

.jpg;width=70;height=70;mode=crop)