Inside Manufacturing

Braided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

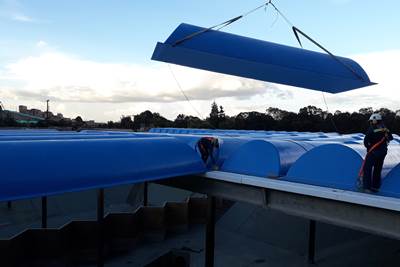

WatchLarge composite covers protect a lot of water

A massive concrete water storage facility in Bogotá, Colombia, gets a much-needed makeover with the resin transfer molding of 840 large composite domes that keep the water potable.

WatchAdvancing the OOA infused wing box

MTorres integrates lower cover, front and rear spars into unitized flying demonstrator using one-shot, low-cost, portable production.

Read MoreBuilding the Museum of the Future

FR composite panels provide structure, sealing and iconic facade for pioneering architecture in Dubai.

Read MoreC-FREX exoskeleton depends on CFRP for unpowered movement

C-FREX uses a novel design and CFRP to overcome the heaviness and weakness of metallic exoskeletons.

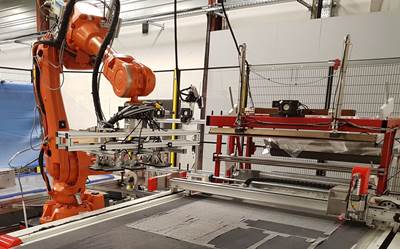

WatchHigh-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

Read MoreCompression RTM for production of future aerostructures

Automated preforming and 5-min resin infiltration show a way forward for lower-cost CFRP primary structures.

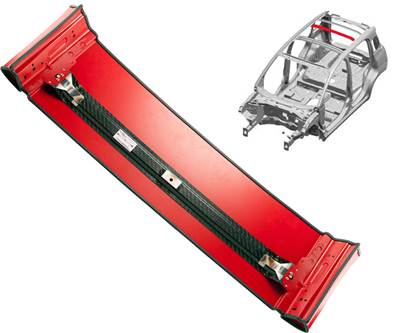

Read MoreOvermolded hybrid parts open new composites markets

A process that combines continuous carbon fiber-reinforced PAEK with chopped fiber/PEEK overmolding is making inroads in the aerospace market. Parts that previously could not be produced cost-effectively from composites can now be made at less cost than their metal counterparts.

Read MoreAutomated joining of hybrid metal-thermoplastic composite structures

The FlexHyJoin production cell combines surface structuring, induction and laser joining and NDT for automotive mass production.

Read MoreFilament wound utility poles offer design flexibility

In Turkey, a utility pole manufacturer combines filament winding, automation, glass and carbon fiber composites to expand its product line.

Watch