Remotely installing an AFP system amid COVID-19 travel restrictions

Addcomposites has completed remote installation of AFP-XS for Regional Institute of Advanced Materials (IRMA) in France.

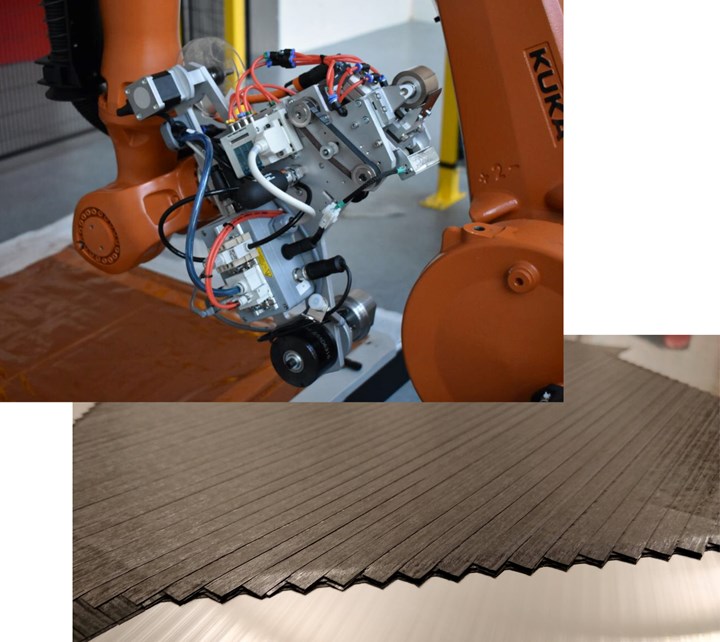

Despite COVID-19 travel restrictions, Addcomposites (Espoo, Finland) has completed the installation of its AFP-XS automated fiber placement (AFP) system to IRMA (Regional Institute of Advanced Materials) in Ploemeur, France. The installation was supported remotely, by creating a visual installation guide in coordination with IRMA’s trusted local integrator. The integrator successfully completed the installation without the Addcomposites team physically present during the integration.

IRMA creates innovative plastics and composites - formulating “tailor-made” solutions upon request. IRMA uses specialized composite materials based on fused deposition modeling (FDM) and AFP with short fibers (FDM), long fibers (FDM assisted by extrusion) and continuous fibers (AFP). The newly installed AFP-XS from Addcomposites will complement IRMA’s fleet of composite fiber deposition machines with digital tools (AddPath) and different draping technologies.

Addcomposites started its operation in mid-2018 with the primary goal to make aerospace-grade composites manufacturing accessible to all industries. The AFP-XS is built upon a Plug-n-Produce Platform (PPP) and can be installed and operational within a day. Future installations can be performed remotely (with online support from the Addcomposites team) or in-person, depending on the user’s preference.

The team is now gearing to launch its laser-assisted fiber placement, complete cell design, and installation services, along with launching AddPath, our purpose-built offline programming (OLP) software, in the coming months. For more information on how Addcomposites can help you get started with AFP, contact info@addcomposites.com.

Addcomposites’ activities have been supported by Business Finland, European Space Agency, and our trusted partners and customers.

Related Content

-

Inside the MFFD — CW's coverage of the Clean Aviation multifunctional fuselage demonstrator

CompositesWorld rounds up coverage of the MFFD project over the past decade. Now complete, the MFFD illustrates numerous processes and technologies for manufacturing primary aerospace structures using thermoplastic composites.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

-

Mikrosam equips BTU Germany with single-tape AFP head for Type 5 pressure vessels

Delivery of upgraded placement head provides additional automated layup flexibility, quality control for the university’s latest projects advancing Type 4 and 5 hydrogen storage.