Mussel Polymers announces new multifunctional carbon, aramid fiber coating

Specialty materials company produces poly(catechol-styrene) polymer that effectively bonds with many materials, providing enhanced adhesion and other surface functionalizing benefits.

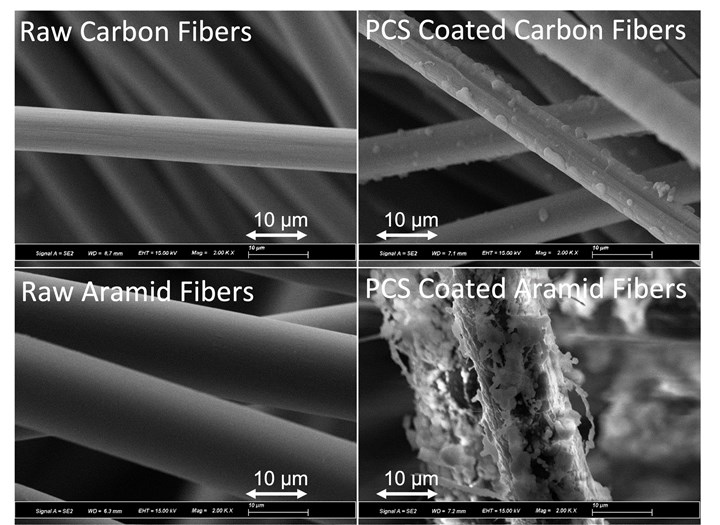

Shown here are PCS-coated carbon and aramid fibers. (A) depicts scanning electron microscope (SEM) micrographs of raw carbon fibers (B) PCS-coated carbon fibers, (C) raw aramid fibers and (D) PCS-coated aramid fibers. Photo Credit: Mussel Polymers Inc.

In September 2022, Mussel Polymers Inc. (MPI, Bethlehem, Pa., U.S.) a specialty materials and coatings startup company from Purdue University (West Lafayette, Ind., U.S.), announced that it successfully coated carbon and aramid fibers with its bio-inspired poly(catechol-styrene) (PCS) catechol-containing polymer, which it says is a step forward in producing lighter, stronger fiber-reinforced composites.

According to MPI, PCS coatings improve bonding for a wide range of adhesive and composite chemistries while functionalizing material surfaces. This application of PCS is likely to significantly increase the strength and impact energy of fiber-reinforced materials and improve the use of coatings and adhesives with carbon fiber parts and materials.

While carbon and aramid fibers possess many positive attributes, they are notoriously difficult to bond with because they are smooth and chemically inert. Previous work coating carbon and aramid fibers with polydopamine (PDA), a catechol containing research agent-like PCS, showed that the shear strength of a single coated fiber pulled from its matrix increased more than 200% compared to that of a raw fiber. Further, the flexural strength and impact energy of reinforced composites made with the catechol-coated fibers increased more than 200%.

PCS is reported to be the first commercially available catechol compound used to coat carbon fibers, among its many other uses. MPI is developing products for applications in the dental, biomedical, defense, specialty coatings, industrial and marine industries.

“The MPI team successfully coated carbon and aramid fibers with PCS using a simple one-step, room temperature process,” Jason Stieg, chief commercial officer (CCO) of MPI, says. “These coated fibers were examined under the scanning electron microscope [SEM] at Lehigh University [Bethlehem, Pa., U.S.]. The resulting images were striking and showed complete coverage of the fibers. The ability of our polymer to bond to these surfaces has applicability in both advanced composite materials and the assembly and coating of carbon fiber parts.”

George Boyajian, CEO of MPI, says the company expects to expand its partnerships with new materials and products companies. Furthermore, the simplicity of the coating process may accelerate its adoption and enable safer and more environmentally sound materials.

Mussel Polymers is currently in discussions to jointly develop new composite materials with its PCS.

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

-

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?