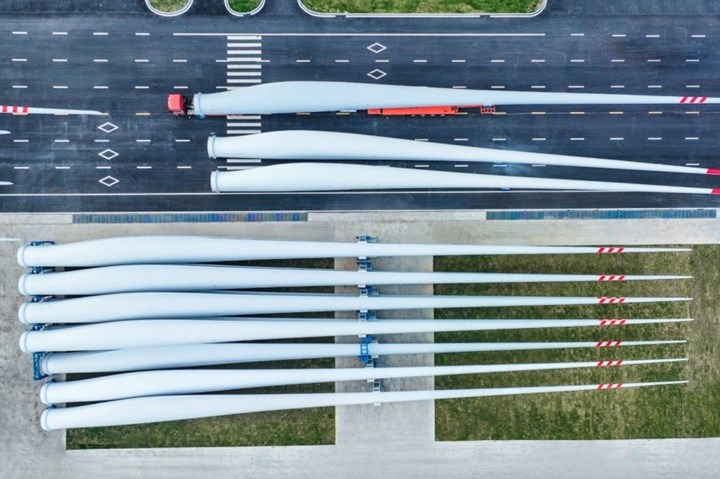

China’s Sany Renewable rolls out 131-meter wind blade

Sany reports that it has adopted an optimized airfoil design with greater thickness and a blunt trailing edge to augment strength and stability.

Source: Sany Renewable Energy via LinkedIn

Chinese wind blade manufactureer Sany Renewable Energy (Beijing) has announced the rollout of a 131-meter wind blade, claiming that it has implemented several key blade design advancements — focusing on both strength and reliability — to enable a more robust structure.

Sany reports in a LinkedIn post that SY1310A retains an “optimized airfoil design with greater thickness and a blunt trailing edge.” Moreover, the new manufacturing process technologies aided in its successful development, including self-designed fiberglass pre-quilting technology, long-distance automatic infusion technology for large composite blades and 3D design for trailing edge blind bonding inserts.

Upgraded pultruded spar cap from glass to carbon fiber, along with the adoption of reinforcement and shear web on the trailing edge, improve stiffness and stability. In an effort to actively pursue sustainability, recyclable polyurethane structural parts have also been incorporated to enhance the recyclability of ultra-long blades.

One source indicates that the turbine blade is expected to be first used for its 10-megawatt (MW) turbines at an onshore facility in Germany, where Sany would also like to build another facility. Rechargenews.com notes that “the new blades will later be applied to the future 15-MW wind turbine that was unveiled at the 2023 Beijing International Wind Energy Conference and Exhibition in October, where it was proclaimed as the world's largest onshore wind turbine.”

For reference, the blades on Vestas’ (Aardus, Denmark) flagship V236 15-MW offshore wind turbine come in at 115.5 meters. China’s Mingyang (Guangdong) unveiled an 18-MW offshore design with 140-meter blades in October 2023.

Related Content

-

Trends fueling the composites recycling movement

Various recycling methods are being considered for composites, from novel dismantling and processing, to building capacity and demonstrating secondary use applications.

-

Plant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

-

We4Ce infused 2.5-3-MW rotor blade design passes validation test

Composite rotor blade structure design by We4Ce, mold and prototype production by InDutch Composites and fatigue testing by Suzlon Group has resulted in the novel blade’s IEC61400-5:2020 certification.