Offshore wind turbine construction begins for South Fork Wind

The 130-megawatt utility-scale wind farm off the coast of Long Island leads state efforts to install 9 gigawatts of offshore wind by 2035.

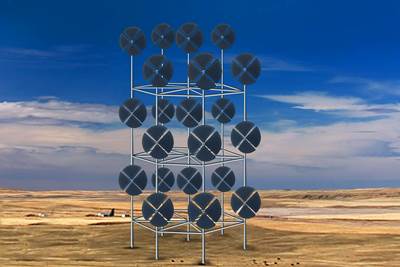

South Fork Wind turbine installation. Photo Credit: South Fork Wind

On Nov. 20, New York completed installation of the first offshore wind turbine for South Fork Wind, to be a utility-scale wind farm in U.S. federal waters. Once completed, the 130-megawatt (MW) offshore wind farm will address a growing reliability challenge for Long Island’s electrical grid, while also generating enough renewable energy to power approximately 70,000 homes, eliminating up to six million tons of carbon emissions, or the equivalent of taking 60,000 cars off the road annually over a 25-year period. The development supports progress toward the state’s Climate Leadership and Community Protection Act goal to install 9 gigawatts (GW) of offshore wind by 2035.

The first of South Fork Wind’s 12 Siemens Gamesa (Zamudio, Spain) wind turbine generators was hoisted into place by the offshore construction team at the project site 35 miles off Montauk, New York. Hundreds of U.S. workers and three Northeast ports have supported South Fork Wind’s construction, helping to stand up the foundations of a new domestic supply chain that’s creating local jobs across the northeast. All 12 turbines are expected to be installed by the end of 2023 or early 2024.

“We congratulate our partners at Ørsted, Eversource and LIPA as this first turbine at South Fork Wind represents a momentous milestone in our efforts to bring the benefits of clean, renewable offshore wind energy to New York,” Nyserda president and CEO Doreen M. Harris says.

First approved by the LIPA Board of Trustees in 2017, South Fork Wind began construction in February 2022, beginning with the onshore export cable system that links the project to the local energy grid, which was completed early this year. The wind farm reached its “steel in the water” milestone in June 2023 with the installation of the project’s first monopile foundation.

Maritime company Van Oord’s (Rotterdam, Netherlands) offshore installation vessel, the Aeolus, is installing the turbines. Turbine installation involves using a crane to place the steel turbine tower onto the foundation. The nacelle and rotor are then installed on top of the tower. Lastly, the blades are lifted and installed one by one by bolting them to the rotor.

Once in operation, South Fork Wind will be supported by U.S.-built crew transfer vessels and eventually by the U.S.’ first offshore wind Service Operations Vessel.

The announcement builds on the momentum established by the New York governor’s announcement earlier this month, which publicized the largest state investment in renewable energy in U.S. history. The conditional awards included three offshore wind and 22 land-based renewable energy projects totaling 6.4 GW of clean energy, enough to power 2.6 million New York homes and deliver approximately 12% of New York’s electricity needs once completed. When coupled with two marquee offshore wind blade and nacelle manufacturing facilities, this portfolio of newly announced projects is expected to create approximately 8,300 family sustaining jobs and spur $20 billion in economic development investments statewide, including developer-committed investments to support disadvantaged communities.

Learn about other U.S. offshore wind project announcements, “U.S. sets offshore energy records with $4.37 billion in winning bids for wind sale.”

Related Content

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

Read MoreRead Next

Vestas secures another U.S. repowering order, looks ahead to wind blade recyclability

A 158-MW order adds to Vestas’ increasing presence in the U.S., not just in wind blade and nacelle manufacturing, but also its initiatives to make blades more recyclable.

Read MoreDOE funds project for 3D-printed wind blade tooling

Targeting U.S. wind energy, the program backs Purdue’s CMSC center and industry partners to develop the foundation for automated tooling manufacture, supporting new innovations in composite materials, other technology elements.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read More

.jpg;maxWidth=300;quality=90)