Advanced Composites Training uses augmented reality to deliver composites training

Virtual system delivers live composite technology training courses for a range of industries without the inconvenience of travel.

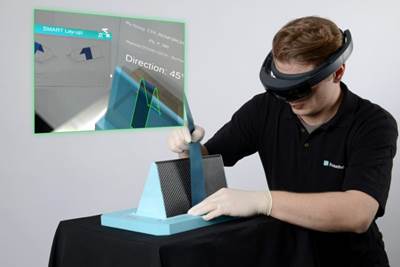

ACT founder Wilson Boynton uses augmented reality to deliver composites training. Photo Credit: ACT

The COVID-19 global pandemic has forced many businesses to find new ways of delivering their goods and services. For Advanced Composites Training (ACT, London, Ontario, Canada), a division of Renaissance Aeronautics Associates (RAA) Inc., that meant developing and launching a new augmented reality system to deliver composites training. Using Microsoft HoloLens2 and software developed by Kognitiv Spark (Brunswick, Canada), ACT is able to offer live courses to students globally.

ACT founder, Wilson Boynton, believes his company is the first to use augmented reality to deliver intensive composites technology training for the aerospace, aviation, automotive, marine and renewable energy industries.

“This is a huge benefit to our clients who are considered essential workers worldwide, but who may not be able to come to London due to travel and quarantine restrictions,” says Boynton. “It also allows us to increase our class sizes, since physical distancing is not a factor.” As the only privately-owned Canadian composites training institute exceeding both Transport Canada and American Federal Aviation Administration standards, ACT works with both civilian and military technicians from more than 39 countries.

ACT offers 17 courses covering all aspects of composites manufacturing and structural repair technologies. According to the company, technicians typically travel to London, Canada for intense on-site training, which combines a mix of theory and hands-on instruction.

However, demand for composites training has remained strong since the beginning of the pandemic, says Boynton, prompting the decision to explore virtual training options. “Augmented reality allows us to project holograms that the instructor sees through the HoloLens,” he says. Students tune in from their laptop or other digital device. “They see exactly what the instructor sees. It’s like having someone looking through your eyes while you are doing the work.”

Reaction to ACT’s augmented reality training has been positive. “Clients are very satisfied,” says Boynton. “Students get the experience of being here, without having to travel.” The launch of augmented reality training is the latest in a number of exciting milestones for ACT.

This February, Boynton enjoyed the thrill of watching NASA’s Perseverance rover land on Mars. Less than two years ago, he was invited to NASA’s Jet Propulsion Laboratory (JPL, Pasadena, Calif., U.S.) to provide training in the composite materials used in its construction. “Composites made the whole thing possible,” he notes.

April 2021, ACT also celebrates 25 years in business. The company plans to celebrate with a 25th Anniversary Virtual Open House on May 11, 2021. “People can take a virtual tour of our facility through the use of the HoloLens and learn more about our training options,” Boynton says.

While augmented reality training will continue to allow technicians from around the world to strengthen their composites knowledge without the inconvenience of travel — long after the global pandemic is over — Boynton believes it will never completely replace the in-class experience.

“Technicians are tactile learners,” he says. “Augmented reality training is an effective way to deliver the vast majority of the knowledge people need to be comfortable working with composites, but it will never completely replace hands-on learning.”

Related Content

SAMPE launches 2026 Emerging Engineers Challenge

Early-career engineers are invited to submit design concepts by Dec. 8, focused on enhancing a manufacturing process using advanced materials, robotics, data analytics or machine learning.

Read MoreHands-on composites training, M&P engineering consulting services

CAMX 2025: Set up in its new facility in Spark, Nevada, Abaris is highlighting its training capabilities, course offerings, and customer consultation and technical assistance.

Read MoreSAMPE 2025: Innovation, circularity and connection drive composites forward

Collaboration, workforce development and an ongoing focus on scalability and sustainability took center stage at SAMPE 2025 in Indianapolis.

Read MoreIACMI celebrates 10th anniversary at Members Meeting

Event in Dayton recapped the Institute’s successes, set future goals, celebrated the retirement of COO Dale Brosius and more.

Read MoreRead Next

Augmented reality system facilitates FRP component preforming

The software makes exact alignment and position of materials directly visible on the component.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More