Out of Autoclave

KAI demonstrates thermoplastic and infused structures for future airframes

Korea Aerospace Industries advances its expertise through a welded TPC fuselage section and resin-infused wing skin module and torsion box demonstrators.

Ginger Gardiner

Executive Editor, CompositesWorld

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreCirrus G3 Vision Jet unveiling builds upon years of composites and safety expertise

An evolutionary update to the single-engine personal jet featuring a reimagined interior, increased seating capacity and more safety innovations is backed by Cirrus’ ongoing composites fabrication operations.

Read MoreDonghua University demonstrates in situ consolidation of thick low-melt PAEK laminates

SNAPSHOT: Even without using heated tooling, the Center for Civil Aviation Composites achieved thermoplastic composite laminates with <1% voids, near-zero warpage and good consolidation, showing potential for OOA production.

Read MoreSyensqo, Teijin Carbon achieve aerospace qualification for composite resin

Resin infusion system Prism EP2400 achieves NCAMP qualification with Teijin Carbon’s advanced NCF and UD reinforcements.

Read MoreEpisode 51: Francesco Ierullo, Exel Composites

Francesco Ierullo, vice president of sales and marketing, Exel Composites discusses the role the composites manufacturing processes of pultrusion and pull-winding are playing in infrastructure and renewable energy applications today.

Read MoreClean Aviation's regional aircraft technology testbed #2 demonstrates advances with composites

European project advances OOA outer wing box using resin infusion and thermoplastic composite technologies.

Read MorePrepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

Hannah Mason

Technical Editor, CompositesWorld

Composite Integration presents webinar on liquid resin infusion

On July 30, 2025, company experts will discuss the role of LRI in delivering scalable, OOA composite production for the aerospace sector.

Read MoreAM method enables tool-free, energy-efficient thermoset composites production

University researchers highlight how the combination of a thermally curable resin system with photothermal curing eliminates the post-curing steps involved in discontinuous, continuous fiber parts fabrication.

Read MoreFlyber launches U.K. composites manufacturing site for advanced mobility applications

The startup’s design automation and composite material layup and curing technologies target lightweighting for aerospace, UAVs, eVTOL and high-performance mobility platforms.

Read MoreClean Sky 2 outer wing box demonstrator validates OOA LRI, shimless assembly and SHM

Full-scale wing box project achieves TRL 5 with 2% weight reduction and 4% reduction in recurring production costs through improved manufacturing efficiency and assembly processes.

Read MoreInduction heating system enables OOA composites processing

JEC World 2025: Roctool focuses attendees’ attention on the light induction tooling (LIT) system targeting efficiency, sustainability and performance.

Read MoreCOMPINNOV TP2 project promotes use of thermoplastics in aerospace

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Stewart Mitchell

Contributing Writer

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreSmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreGKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

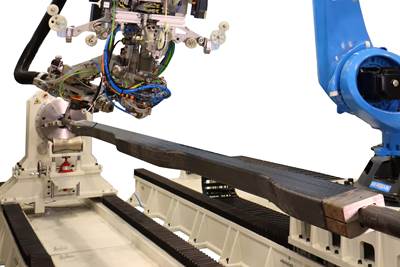

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Ginger Gardiner

Executive Editor, CompositesWorld

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreTrelleborg launches low-friction thermoplastic composite bearing

The HiMod Advanced Composite Bearing Plus is a dual-layer bearing with a low-friction PEEK liner that doubles as an impermeable sealing surface, in addition to 50% less sliding friction, increased wear performance.

Read More