Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

The structural properties of composite materials are derived primarily from the fiber reinforcement. In a composite, the fiber, held in place by the matrix resin, contributes tensile strength, enhancing performance properties in the final part, such as strength and stiffness, while minimizing weight. Fiber properties are determined by the fiber manufacturing process and the ingredients and coating chemistries used in the process.

Glass fibers

The majority of all fibers used in the composites industry are glass. Glass fibers are the oldest and, by far, the most common reinforcement in most end-market applications (the aerospace industry is a significant exception) to replace heavier metal parts. Glass fiber weighs more than the second most common reinforcement, carbon fiber, and is not as stiff, but is more impact-resistant and has a greater elongation-to-break (that is, it elongates to a greater degree before it breaks). Depending upon the glass type, filament diameter, coating chemistry (called “sizing,” see “Critical fiber sizing," below) and fiber form, a wide range of properties and performance levels can be achieved.

To make glass fiber, raw materials are melted and drawn into delicate and highly abrasive filaments, ranging in diameter from 3.5 to 24 μm. Silica sand is the primary raw ingredient, typically accounting for more than 50% of glass fiber weight. Metal oxides and other ingredients can be added to the silica, and processing methods can be varied to customize the fibers for particular applications.

Continuous glass filaments are supplied in bundles called strands. Roving generally refers to a bundle of untwisted strands, packaged, like thread, on a large spool. Single-end roving consists of strands that are made up of multiple continuous glass filaments that run the length of the strand. Multiple-end roving contains lengthy but not entirely continuous strands, which are added or dropped in a staggered arrangement during the spooling process. Yarn is a collection of strands that are twisted together.

Electrical or E-glass, so named because its chemical composition makes it an excellent electrical insulator, is particularly well-suited to applications in which radio-signal transparency is desired, such as aircraft radomes, antennae and printed circuit boards (PCBs; see CW’s report on the shifting role of glass fiber reinforcement in PCBs: “Printed circuit boards: A mobile market,”). However, it is also the most economical glass fiber for composites, offering sufficient strength to meet the performance requirements in many applications at a relatively low cost. It has become the standard form of fiberglass, accounting for more than 90% of all glass-fiber reinforcements. At least 50% of E-glass fibers are made up of silica oxide; the balance comprises oxides of aluminum, boron, calcium and/or other compounds, including limestone, fluorspar, boric acid and clay.

When greater strength is desired, high-strength glass, first developed for military applications in the 1960s, is an option. Known by several names — S-glass in the US, R-glass in Europe and T-glass in Japan, its strand tensile strength is approximately 700 ksi, with a tensile modulus of up to 14 Msi. S-glass has appreciably greater silica oxide, aluminum oxide and magnesium oxide content than E-glass and is 40-70% stronger than E-glass.

E-glass and S-glass lose up to half of their tensile strength as temperatures increase from ambient to 540°C, although both fiber types still exhibit generally good strength in this elevated temperature range. Manufacturers are continually tweaking S-glass formulations. An S-3 UHM (for ultra-high modulus) Glass, for example, was introduced by AGY Holding Corp. (Aiken, SC, US) several years ago. The upgraded S-3 glass has a tensile modulus of 14,359 — higher than S-glass and 40% higher than E-glass — due to improved fiber manufacturing as well as proprietary additives and melt chemistry.

Although glass fibers have relatively high chemical resistance, they can be eroded by leaching action when exposed to water. For example, an E-glass filament 10μ in diameter typically loses 0.7% of its weight when placed in hot water for 24 hours. The erosion rate, however, slows significantly because the leached glass forms a protective barrier on the outside of the filament; only 0.9% total weight loss occurs after seven days of exposure. To slow erosion, moisture-resistant sizings, such as silane compounds, are applied during fiber manufacturing.

Corrosion-resistant glass, known as C-glass or E-CR glass, stands up better to an acid solution than does E-glass. However, E-glass and S-glass are much more resistant to sodium carbonate solution (a base) than is C-glass. A boron-free glass fiber, with performance and price comparable to E-glass, demonstrates greater corrosion resistance in acidic environments (similar to that of E-CR glass), higher elastic modulus and better performance in high temperatures than does E-glass. In addition, taking boron out of the manufacturing process produces fewer environmental impacts, a decided advantage.

High-performance fibers

High-performance fibers used in advanced composites include carbon fiber, aramid fiber (known by the trade names Kevlar and Twaron), boron fibers, high-performance polypropylene fiber, ultra high molecular weight polyethylene (PE), newer fibers such as poly p-phenylene-2,6-benzobisoxazole (PBO), and hybrid combinations, as well.

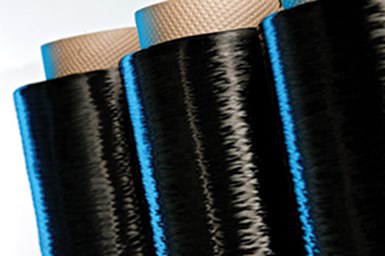

The fiber is the composite's primary source of the strength and stiffness. Fibers must be treated with chemicals, called sizings, that make them compatible with the intended matrix and ease processing. These rolls contain Tenax carbon fiber filament yarn, recently introduced by Toho Tenax Europe GmbH (Wuppertal, Gemany) with a new tailored sizing that makes the fibers compatible with thermoplastic resin matrices and useful in high-temperature composites applications. Source: Toho Tenax

Carbon fiber — by far the most widely used fiber in high-performance applications — is produced from a variety of precursors, including polyacrylonitrile (PAN), rayon, pitch as well as bio-based, carbon-rich precursors such as lignin or bio-based PAN. The precursor fibers are chemically treated, heated and stretched, then carbonized, to create the high-strength fibers. The first high-performance carbon fibers on the market were made from rayon precursor. PAN-based carbon fibers have long since replaced rayon in structural applications, but the latter’s “dogbone” cross-section and high-temperature performance often makes it the fiber of choice for carbon/carbon (C/C) composites in ablative heat shields. PAN-based carbon fibers are the most versatile and widely used. They offer an amazing range of properties, including excellent strength — to 1,000 ksi — and high stiffness. Pitch fibers, made from petroleum or coal tar pitches, have high to extremely high stiffness and low to negative axial coefficient of thermal expansion (CTE). Their CTE properties are especially useful in spacecraft applications that require thermal management, such as electronic instrument housings. Carbon fiber’s properties are stimulating searches for alternative and less expensive precursor materials, such as lignin derived from pulp and paper waste. Research efforts are gaining traction for such low-cost fiber materials and they are on the way to becoming viable commercial reinforcement choices, thanks to research efforts at Oak Ridge National Laboratory (Oak Ridge, TN, US) and other groups.

Although they are stronger than glass or aramid fibers, carbon fibers are not only less impact-resistant but also can cause galvanic corrosion in metals they contact, because of their electrical conductivity. Fabricators overcome the latter problem by using a barrier material or veil ply — often fiberglass/epoxy — during laminate layup.

The basic fiber form for high-performance carbon fiber is bundles of continuous fibers called tows. A carbon fiber tow consists of thousands of continuous, untwisted filaments, with the filament count designated by a number followed by “K,” indicating multiplication by 1,000 (e.g., 12K indicates a filament count of 12,000). Tows may be used directly, in processes such as filament winding or pultrusion, or may be converted into unidirectional tape, fabric and other reinforcement forms (for more about fiber forms, see “Fiber reinforcement forms.”

“Spread tow” fabrics are gaining popularity. As the name implies, the filaments in each tow are spread out to form very thin, wide “tapes” that are then woven. Such fabrics deliver very good performance at very low weight. Oxeon (Borås, Sweden) is a well-known purveyor of spread-tow fabrics, tradmarked TeXtreme, and other fiber converters are following suit.

Aramid fibers, formed from aromatic polyamide, provide exceptional impact resistance and good elongation (higher than carbon, but less than glass). Standard, high-performance aramid fiber has a modulus of about 20 Msi, tensile strength of approximately 500 ksi and elongation of nearly 3%.

Renowned for its performance in bulletproof vests and other armor and ballistic applications, aramid fiber has been in demand in part due to the need for personnel protection and armor in law-enforcement and military markets. Aramid’s properties also make the fiber an excellent choice for helicopter rotor blades, marine vessel hulls and sporting goods where impact resistance is desired.

Boron fibers are five times as strong and twice as stiff as steel. They are made by a chemical vapor deposition process in which boron vapors are deposited onto a fine tungsten or carbon filament. Boron provides strength, stiffness and light weight, and possesses excellent compressive properties and buckling resistance. Uses for boron composites range from sporting goods, such as fishing rods, golf club shafts, skis and bicycle frames, to aerospace applications as varied as aircraft empennage skins, truss members and prefabricated aircraft repair patches.

Commercially available ultra high-molecular weight (UHMW) polyethylene (PE) fibers are well known for their extremely light weight, excellent chemical and moisture resistance, outstanding impact resistance, antiballistic properties and low dielectric constant. However, PE fibers have relatively low resistance to elongation under sustained loading, and the upper limit of their use temperature range is about 98°C. PE fiber composites are used in racing boat hulls, ski poles, offshore mooring ropes and other applications that require impact and moisture resistance and light weight but do not need extreme temperature resistance. At least one aircraft manufacturer uses high-modulus PE fibers for the bulletproof insert in cockpit doors.

High-performance polypropylene (PP) fiber is a fairly new olefin-based fiber type for composites, and is produced by Innegra Technologies (Greenville, SC, US) and marketed as Innegra fiber. It is being adopted in applications that exploit its light weight, high ductility and toughness, impact resistance and vibration damping properties. Innegra is often woven into a hybrid fabric with other high-performance fibers to increase material toughness.

Poly p-phenylene-2,6-benzobisoxazole (PBO), known by its trade name Zylon, is a relatively new fiber with modulus and tensile strength almost double that of aramid fiber and a decomposition temperature that is almost 100°C higher. Suitable for high-temperature applications, it is currently used in protective ballistic armor, sporting goods, insulation and tire reinforcements.

The high cost of high-performance fibers can be a deterrent to their selection, if manufacturers neglect to examine how that high cost is mitigated by the greater performance, durability and design freedom these materials bring to a project and the consequent positive effects those advantages have on a key metric: lifecycle cost. This is particularly true for carbon fiber, the selection of which has, historically, been complicated by significant fluctuations in carbon fiber supply and demand. Carbon and other high-performance fibers generate perennially high interest in the state of global fiber markets, a subject treated annually in the SourceBook's "Supply and demand: Advanced fibers" feature. The SourceBook's publisher, CompositesWorld, also offers the yearly Carbon Fiber conference, devoted to examinations of those markets and applications.

Other fiber options

Quartz fibers, while more expensive than glass, have lower density, higher strength and greater stiffness than E-glass, and about twice the elongation-to-break, making them a good choice where durability is a priority. Quartz fibers also have a near-zero coefficient of thermal expansion (CTE) and can maintain their performance properties under continuous exposure to temperatures as high as 1050°C and up to 1250°C for short time periods. Quartz fibers possess significantly better electromagnetic properties than glass, a plus when fabricating parts such as aircraft radomes that protect radar systems and other key electronic equipment.

Ceramic fibers offer high to very high temperature resistance but low impact resistance and relatively poor room-temperature properties. Typically much more expensive than other fibers, ceramic, like quartz, is the fiber of choice when its advantages justify the extra cost. One application of ceramic fibers is for flame-resistant veil material in laminates for aircraft interiors, which must withstand 1093°C for at least 15 minutes without flame penetration. Ceramic composites, which combine ceramic or silicon carbide fibers in a ceramic matrix are now being more widely adopted for use in certain high-heat aircraft engine applications. (To read more about ceramic-matrix composites in jet engines see "Aeroengine Composites, Part 1: The CMC invasion.")

Basalt fibers are inexpensive, golden brown-colored fibers, similar to glass, and historically produced in Russia and Ukraine. Kamenny Vek (Dubna, Russia), Sudaglass Fiber Technology Inc. (Houston, TX, US) and Technobasalt-Invest LLC (Kyiv, Ukraine) have been basalt fiber suppliers. A new supplier, Mafic (Kells, County Meath, Ireland), offers basalt fibers in both continuous form and as long-fiber thermoplastic pellets, and mines and produces its basalt fiber in Ireland.

Basalt reportedly exhibits somewhat better chemical and alkali resistance than glass and is said to offer an alternative to glass fiber in composite rebar used to reinforce concrete in civil infrastructure and building construction applications. Basalt’s market share, however, has decreased somewhat over the past several years due to issues with product consistency because the composition of the basalt rock from which the fibers are manufactured varies, based on the quarry from which it is extracted. That said, there is evidence from testing in Europe that basalt fiber can clearly outperform E-glass (see the article "Can basalt fiber bridge the gap between glass and carbon?"

Fiber hybrids capitalize on the best properties of more than one fiber type and can reduce raw material costs. Hybrid composites that combine carbon/aramid or carbon/glass fibers have been used successfully in ribbed aircraft engine thrust reversers, telescope mirrors, driveshafts for ground transportation vehicles, and in the infrastructure arena, in column-wrapping systems that reinforce concrete structural members.

Natural fibers — abaca, bamboo, coconut, flax, hemp, jute, kenaf and sisal are the most common — are derived from the bast or outer stem of certain plants. Natural fibers are enjoying increased use because of their very low weight, adequate structural performance, and their “green” attributes including recyclability. The latter include lower cost (less energy is expended in their production), sustainability (they are biodegradable, and renewable) and carbon dioxide neutrality. They also have the lowest density of any structural fiber but possess sufficient stiffness and strength for some applications. Read CW's article on the bio-fiber reinforcements market, "Natural fiber composites: Market share, one part at a time."

With decades of development work behind it, the natural fibers industry is maturing. Indeed, it appears to be on the verge of leveraging the products’ numerous cost, performance and environmental benefits to big-time technical and potentially high-volume commercial applications. Pictured here are dyed bamboo fibers that are finding a place in highly decorated products, such a snowboards, surfboards and skis, becuase they have better damping properties than carbon fiber and are also easier and cheaper to color than glass fiber. Source | Sunstrand

The automotive industry, in particular, is using these fibers in traditionally unreinforced plastic parts and even employs them as an alternative to glass fibers in auto interiors. Natural fiber-reinforced thermosets and thermoplastics are most often found in door panels, package trays, seat backs, headliners and trunk liners in cars and trucks. European fabricators hold the lead in use of these materials, in part because regulations now require their automobile components to be almost completely recyclable, but The Ford Motor Co. (Detroit, MI, US) in the US has developed a host of natural fiber and bio-resin-based parts for its cars. Natural fibers can be incorporated into molded or extruded parts and, more recently, have been used in the direct long fiber injection (D-LFT) process where kenaf, flax and natural fiber/glass hybrids are used to reinforce polypropylene. Studies are underway to determine the suitability of long natural fiber composites for structural applications.

Critical fiber sizing

To achieve desirable properties in composite components, adhesion between the fiber and the matrix must be optimized. This bond at the fiber/matrix interface requires saturation of the fiber bundle with resin (termed wetout). To ensure good adhesion, attention must be given to fiber surface preparation, such as the use of a surface coating or coupling agent, termed sizing. Sizing, applied to fiber filaments immediately after their formation, actually serves two purposes: It not only enhances the fiber/matrix bond but it also provides a dry lubricant on the fiber surface that protects the fiber from abrasion and breakage during downstream handling, such as weaving or prepregging. Although it accounts for only 0.25-6.0% of total fiber weight, sizing is a dynamic force in fiber reinforcement performance.

Sizing chemistry is one of the primary attributes that distinguish each manufacturer’s fiber products from those of its competitors. It can be customized to optimize fiber performance in particular manufacturing processes, such as pultrusion, filament winding and weaving. For example, developments in sizing formulations have variously resulted in more cleanly chopped glass with reduced “fuzz” (caused by abrasion) and glass that wets out more efficiently.

Historically, carbon fiber was sized only for compatibility with epoxy resin. Today, fiber manufacturers are responding to demands from fabricators and OEMs to produce carbon fibers that are compatible with a broader range of resins and processes, as carbon fiber use increases in applications outside the aerospace arena. Many high-performance fiber producers now offer optimized sizings that are compatible with thermoplastic resins, particularly for high-speed automotive part processing.

This article was originally published 3/17/2016, updated 7/1/2022

Related Content

Carbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

Read MoreAn outlook on China’s carbon fiber market

This analysis sheds additional light on the insights, observations and data shared in ATA Industrial Group’s carbon fiber market report on global and Chinese industry players.

Read MorePrepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreRead Next

Can we make recycled carbon fiber “sexy”?

Although we have methods to create useful product forms from recovered fiber, creating demand for those products will require new entrepreneurial effort.

Read MoreNatural fiber composites: Market share, one part at a time

Suppliers and adventurous composites fabricators put the “feel good” aspect in the rearview mirror, winning customers by competing on price and performance.

Read MoreCan basalt fiber bridge the gap between glass and carbon?

When I started writing about composites in the way, way back, industry innovator Brandt Goldsworthy was still alive. His article on basalt fiber was one of the most-read columns in the old Composites Technology book, and there seems to be a lot of interest in this alternative performance fiber. Mafic SA is a new player in the basalt fiber market.

Read More