Additive Manufacturing/ 3D Printing Using Composites

Additive manufacturing, commonly known as 3D printing, has revolutionized composite production by enabling the layer-by-layer construction of intricate composite structures. In the realm of composites, additive manufacturing techniques allow for the creation of complex geometries with precise fiber orientations and resin distribution, optimizing material performance. This technology offers the flexibility to customize parts, reduce waste, and experiment with novel composite combinations. By depositing materials layer upon layer, additive manufacturing facilitates the production of lightweight, high-strength components tailored for specific applications in industries such as aerospace, automotive, and healthcare, pushing the boundaries of what's achievable in composite design and fabrication.

ESSENTIAL READING

VIEW ALLAvoiding pitfalls in the design of LFAM composite components

Recoat temperature, part orientation and bead geometry are some key design variables to consider for a successful and reliable large-format additive manufacturing (LFAM) process.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

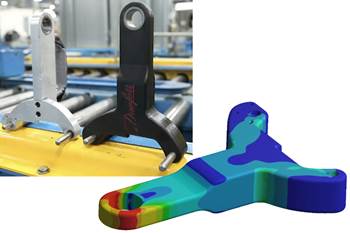

Read MoreHow to validate 3D-printed composite part performance

Integrated Computational Materials Engineering (ICME) workflow simulates composite material performance to speed development, optimize performance and reduce costs for a redesigned 3D-printed CFRP bracket.

Read MoreContactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

WatchLatest Additive Manufacturing News And Updates

LEAM Technologies to present LFAM thermal control results in Feb. 24 webinar

One-hour webinar hosted by MTC, IMechE and AMUK to cover LFAM processing techniques, applications, sustainability and material innovations with LEAM, Airtech and MTC experts.

Read MoreCRP Technology, CRP Meccanica boost Alpine Hy6 concept car with 3D printed intake

A monolithic intake plenum and manifold system, 3D printed with Windform SP CFRTP materials, improves sealing reliability and structural stability for Alpine’s hydrogen V6 engine.

Read MoreAdditive Engineering Solutions acquires Momentous Mold, boosting precision tooling

Two-month acquisition of Momentous Mold & Machine brings 2,000 years of expertise, advanced CNC machining and ITAR-certified solutions to tackle complex aerospace, defense challenges from prototype to production.

Read MoreFormer CEAD experts launch Dutch Boat Factory

SNAPSHOT: Maarten Logtenberg and Charlène van Wingerden take the helm at the newly established Dutch Boat Factory B.V., inheriting assets to efficiently, sustainably build scalable 3D printed boats.

Read MoreTurkish partners form LFAM Center business venture

Basaran Technology, Otostech and Omniform’s combined additive manufacturing and composites expertise will service defense, marine and architectural industries.

Read MoreStack3d demonstrates composite LFAM proficiency with trade show booth furniture series

Functional and recyclable glass fiber-reinforced PETG booth elements are achieved through robotic pellet-extrusion technology.

Read MoreFeatured Posts

3D printed CFRP forms speed construction of concrete nuclear reactor bioshield

In its first demonstration, Kairos Power and Oak Ridge National Laboratory tested the potential of AM and composites to enable fast, repeatable manufacturing for energy construction.

Read MoreKraussMaffei makes LFAM both a product line and an internal benefit

Plastics processing equipment supplier now offers two LFAM machines to customers and to complement its own production uses, enabling a variety of polymer to fiber-filled application options.

Read More3D Fiber Tethering for rapid fabrication of continuous fiber composites

CarbonForm’s 3DFit technology combines robotic, continuous fiber 3D printing and winding to produce small, high-strength, complex parts — like drone frames — in as little as 10 minutes.

WatchCMH-17 updates composites data, will publish new Volume 7 on additive manufacturing

The Composite Materials Handbook-17 is publishing new data and industry best practices, helping to fill the aerospace industry’s growing knowledge transfer gap and support advanced materials and structures.

Read MoreCaracol North American headquarters can produce 100 systems per year

The Italian LFAM systems manufacturer has opened a new facility in Texas that will support application development, service and the production of its turnkey robot-enabled 3D polymer composite printers.

Read MoreOptimizing a CFRP landing leg demonstrator

MT Aerospace achieves design for manufacturing, integrating multiple elements into one-piece structure using AFP and 3D printed tooling to meet time and budget constraints.

WatchFAQ: Additive Manufacturing

What is additive manufacturing in composites?

Additive manufacturing, also known as 3D printing, in composites involves the layer-by-layer deposition of composite materials, such as continuous fibers or chopped fibers within a matrix, to create complex parts or structures.

What types of additive manufacturing methods are used for composites?

Various methods are employed, including Fused Filament Fabrication (FFF), Continuous Fiber 3D Printing (CFF), Binder Jetting, Directed Energy Deposition (DED), and others that selectively deposit materials to build composite parts.

What composite materials can be used in additive manufacturing?

Additive manufacturing processes can work with a range of composite materials, such as carbon fiber-reinforced polymers (CFRPs), glass fiber composites, and even advanced materials like nanocomposites or hybrid composites.

What are the advantages of additive manufacturing in composites?

Benefits include the ability to create complex geometries, lightweight structures, reduced material waste, customization, rapid prototyping, and the integration of functional features within parts.

Are there limitations to additive manufacturing in composites?

Challenges include limitations in scaling for large-scale production, post-processing requirements, ensuring consistent mechanical properties, and the need for advancements in material options.