Materials & Processes: Introduction

High strength at low weight remain the winning combination that propels composite materials into new arenas, but other properties are equally important. This article outlines the case for composites and introduces SourceBook's overview of the materials and processes used to make them.

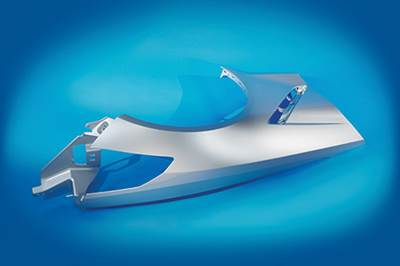

High strength and low weight remain the winning combination that propels composite materials into new arenas, but other properties are equally important. Composite materials offer good vibrational damping and low coefficient of thermal expansion (CTE), characteristics that can be engineered for specialized applications. Composites are resistant to fatigue and provide design/fabrication flexibility that can significantly decrease the number of parts needed for specific applications — which translates into a finished product that requires less raw material, fewer joints and fasteners and shorter assembly time. Composites also have proven resistance to temperature extremes, corrosion and wear, especially in industrial settings, where these properties do much to reduce product lifecycle costs. These characteristics have propelled composites into wide use. The push for fuel economy in the face of rising oil prices, for example, has made lightweighting a priority in almost every mode of mechanical transportation, from bicycles to large commercial aircraft.

Since The Boeing Co.’s (Chicago, IL, US) 787 Dreamliner — 50% composite by weight and 100% composites on its aerodynamic surfaces — entered production and, in December 2009, successfully made its first flight, composites have earned their way into primary and secondary aerospace structures and found a greater place in the aircraft interior in the aerospace world. The 787 has since been joined in the world spotlight by other composites-intensive aircraft from its commerical transport aircraft rival, Airbus (Toulouse, France) and others. The first 52% (by weight) composite Airbus A350 XWB was delivered as 2015 dawned. And Airbus previously incorporated composites into its A380 superjumbo passenger jet and its A400M military transport plane as well. The four programs are a present fulfillment of a long-awaited transformation that has also overtaken the general aviation aircraft market and long been a part of military aircraft manufacture. As the articles that accompany this introductory statement will demonstrate, composites — available in increasingly diverse material forms and manufacturable by an extensive array of molding and forming processes — have taken or are poised to take the spotlight in manufacturing arenas throughout the world.

A definitively different material

Composites differ from traditional materials in that composite parts comprise two distinctly different components — fibers and a matrix material (most often, a polymer resin) — that, when combined, remain discrete but function interactively to make a new material, the properties of which cannot be predicted by simply summing the properties of its components. In fact, one of the major advantages of the fiber/resin combination is its complementary nature. Thin glass fibers, for example, exhibit relatively high tensile strength, but are susceptible to damage. By contrast, most polymer resins are weak in tensile strength but are extremely tough and malleable. When combined, however, the fiber and resin each counteract the other’s weakness, producing a material far more useful than either of its individual components.

The structural properties of composite materials are derived primarily from the fiber reinforcement. Commercial composites for large markets, such as automotive components, boats, consumer goods and corrosion-resistant industrial parts, often are made from noncontinuous, random glass fibers or continuous but nonoriented fiber forms. Advanced composites, initially developed for the military aerospace market, offer performance superior to that of conventional structural metals and now find applications in communication satellites, aircraft, sporting goods, transportation, heavy industry and in the energy sector in oil and gas exploration and wind turbine construction.

High-performance composites derive their structural properties from continuous, oriented, high-strength fiber reinforcement — most commonly carbon, aramid or glass — in a matrix that promotes processability and enhances mechanical properties, such as stiffness and chemical resistance.

Fiber orientation can be controlled, a factor that can improve performance in any application. In composite golf club shafts, for example, boron and carbon fibers oriented at different angles within the composite shaft enable it to take best advantage of their strength and stiffness properties and withstand torque loads and multiple flexural, compressive and tensile forces.

A matrix can be polymeric, ceramic or metallic. The polymer matrices most widely used for composites in commercial and high-performance aerospace applications are thermoset resins, consisting of polymer chains that are permanently cured into a crosslinked network when mixed with a catalyst, exposed to heat, or both. Curing usually occurs under elevated temperature and/or pressure conditions in an oven and/or vacuum bag or in an autoclave. Alternative but less-used curing technologies include electron beam, ultraviolet (UV) radiation, X-ray and microwave processes.

The other most commonly used matrix type is thermoplastic (TP) resin, which is proving an increasingly popular option for composites manufacturers. Thermoplastic linear polymer chains are formed and can be reformed into shaped solids by melting or softening and then cooling the material. Often sold in sheet or panel form, thermoplastics can be processed by in-situ consolidation techniques, such as simple press forming (see “Fabrication methods,”) to make tough, near-net shape parts without the autoclave or vacuum-bag cure required by thermosets. TP reformability offers the potential to correct anomalies or repair in-service damage.

Editor's note: To continue reading articles in "Industry Overivew, Part I: Materials & Processes," you may return to the SourceBook main menu by clicking here.

Related Content

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreBraided thermoplastic composite H2 tanks with co-consolidated molded boss areas to fit EV battery space

BRYSON project demonstrates possible designs, automated manufacturing and low permeability concepts, including EVOH liner and novel PPA matrix.

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Classic harps in carbon fiber

Lever and pedal models less cumbersome, still classy.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreMaterials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

Read More