Infusion

CAMX 2022 exhibit preview: Magnum Venus Products

Rather than sealant tapes for infusion processes, Magnum Venus Products suggests the use of its Secure Vacuum Bag Seal, an inflatable seal designed to fit into a groove built into the perimeter of the mold.

Read MoreCAMX 2022 exhibit preview: Composite Alliance Corp.

Composite part design and fabrication is supported through standard and custom solutions with global tooling, machinery and service supplier Composite Alliance Corp.

Read MorePlant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

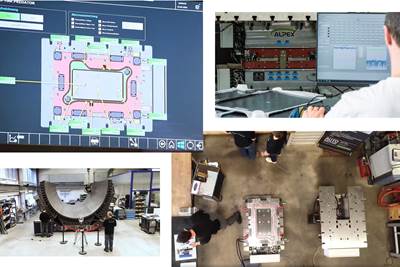

WatchDigitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

Read MoreTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

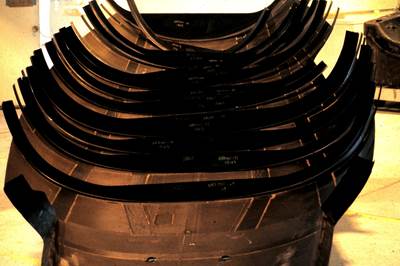

WatchBlue Wind manufactures 1,000 nacelles in 28 months with one mold

Manufacturer combined speed and quality for composite wind turbine nacelles during the pandemic, producing 10 nacelles per week.

Read MoreDoing the twist: A look at dimensional issues in high-temperature cured laminates

When it’s not the tooling, the root cause of dimensionally inaccurate composite parts often boils down to two things: fiber form(s) used and laminate symmetry.

Read MoreMonash Motorsport constructs FSAE autonomous, electric vehicle with ATL Composites materials

Composite are incorporated into the vehicle’s monocoque chassis, aerofoils, aerofoil endplates and other components to suit high aerodynamic loads, minimize mass and enhance efficiency for the globally competitive team.

Read MoreFostering best practices for wet layup procedures

As fabricators continue to manufacture composite tools and parts using an open mold, wet layup process — often with mixed success — it’s important to stress proper preparation, materials, application methods and standardization.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read More